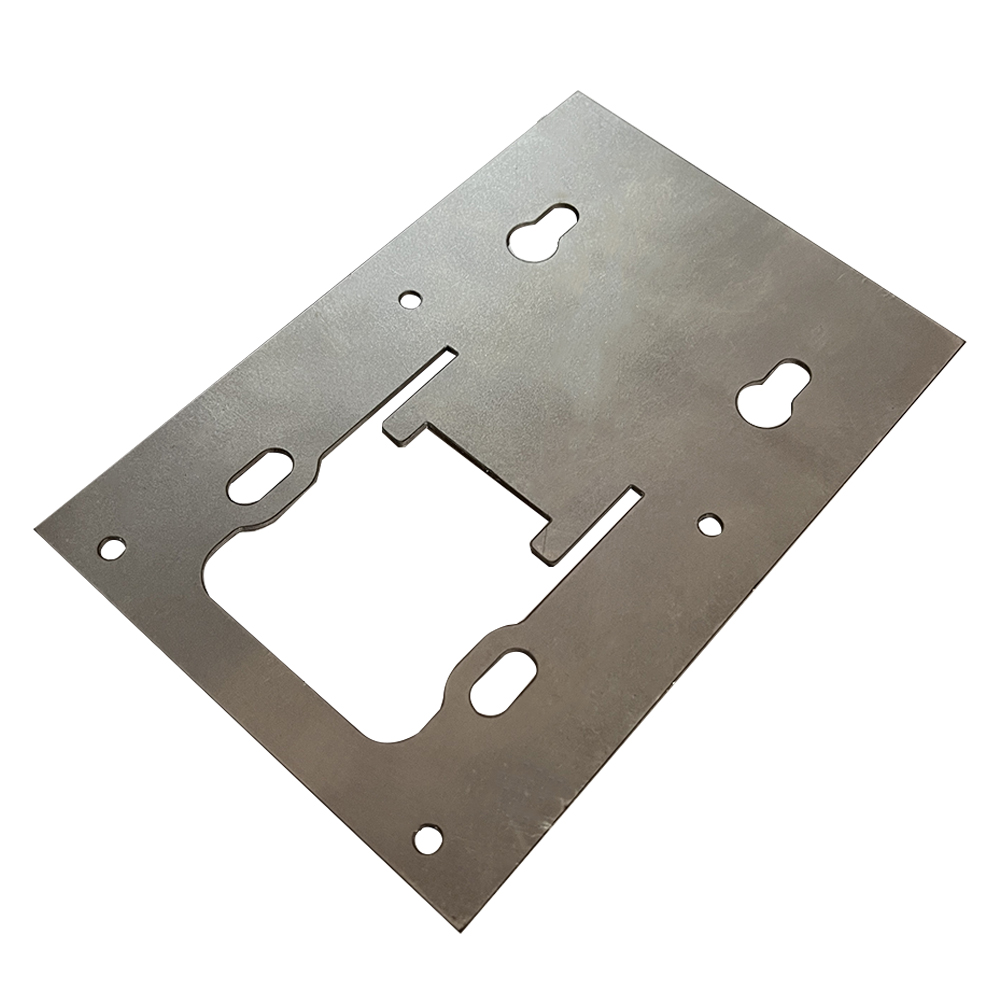

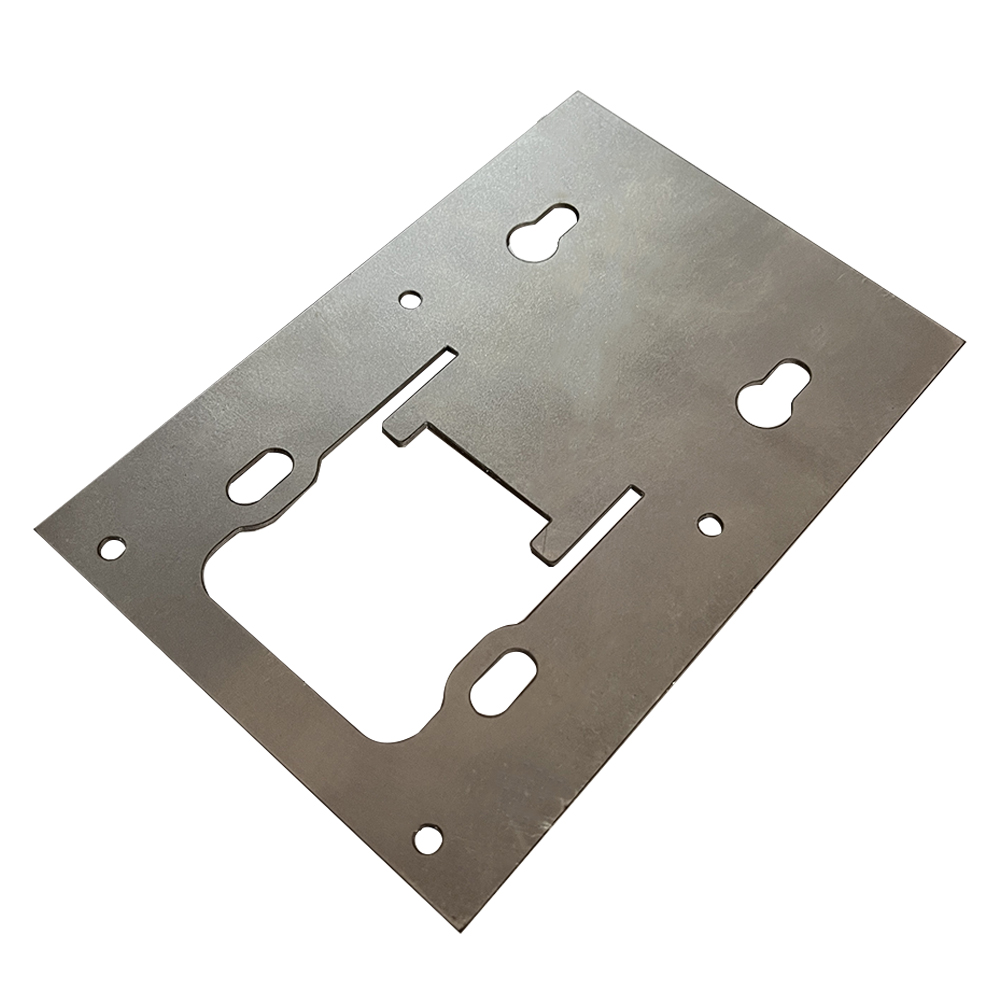

Deep Drawing Sheet Metal Fabrication Forming Process Service Punching Bending Stamping Stainless Steel Product

| Name | Rapid Service Steel Metal Fabrication Metal Bracket Stainless Steel Iron Laser Cutting Service |

| Surface treatment | Plating, Brushing, Polishing, Anodizing, Sandblasting, Knurling, or customer's requirements |

| Material Capacities | Metal: Aluminum alloy, stainless steel, brass, copper, tool steel, carbon steel, iron,

Plastic: ABS, POM, PC(Poly Carbonate), PC+GF, PA(nylon), PA+GF, PMMA(acrylic), PEEK, PEI ,etc |

| CNC processing scope | CNC 3-axis, 4-axis machining, CNC milling, CNC turning, CNC Lathe, High precision 5-Axis turning-milling combined machining |

| Application | Optical instrument, Automotive, Ele ctronic device, Digital communication, UAV, Aerospace, Bicycle, Pneumatic tools, Hydraulic,

Automatic Mechanical, etc |

| Drawing Format | IGS, STP, X_T, DXF, DWG, Pro/E, PDF, PNG, JPG |

| Delivery | DHL, FedEx, EMS, UPS, or customer's requirements |

| | Tissue paper, EPE, standard carton or plastic tray, sponge tray, cardboard tray, etc., can be customized according to customer

requirements |

1、 Laser cutting processing features:

1. Fine - Laser processing penetrates materials with fine cutting seams, and the workpiece is cut according to the design program with high dimensional accuracy. It can cut sharp corners and narrow seams.

2. Smooth - The incision has no burrs, good verticality, and the seam edge is not deformed or has no heat affected zone. The bright cutting edge can be directly welded into shape.

3. Fast - Focused laser beam with small light points, concentrated energy, high power density, like a sharp knife, fast cutting speed.

2、 Laser cutting processing objects

1. Except for gold, silver, and copper with high light reflectivity, the vast majority of materials can be cut by laser, suitable for carbon steel and stainless steel.

2. Various mechanical manufacturing sheet metal parts for medium and small batch material processing.

3. The use of laser cutting processing is an ideal choice for new product trial parts that are economically uneconomical or do not have enough time to open molds.

4. Complex shapes and multiple types of workpieces.

5. Materials and workpieces that cannot be processed or meet quality requirements using conventional cutting methods.

6. Works, quantities, cutting tools, and various metal and non-metal materials for font and graphic decorations, but PVC and other toxic vapor materials are not suitable.

3、 Characteristics of metal laser cutting processing:

1. High material utilization rate: the cutting seam width can be as small as 0.1mm, generally within the range of 0.1-0.3. Can be used for precision machining, with high workpiece accuracy and convenient nesting.

2. Small heat affected zone: generally within the range of 0.1-0.15mm, the workpiece deformation is small. 3. Laser cutting has no mechanical stress and surface damage.

4. The quality of the cut section is good.

5. The incision can be made in any direction and can be cut from any point. 6. Laser cutting is fast and efficient.

7. Fine machining without tool wear and does not require molds.

8. High degree of automation: convenient to use.

9. Low noise, pollution-free.

10. Mature technology and programmed laser cutting.