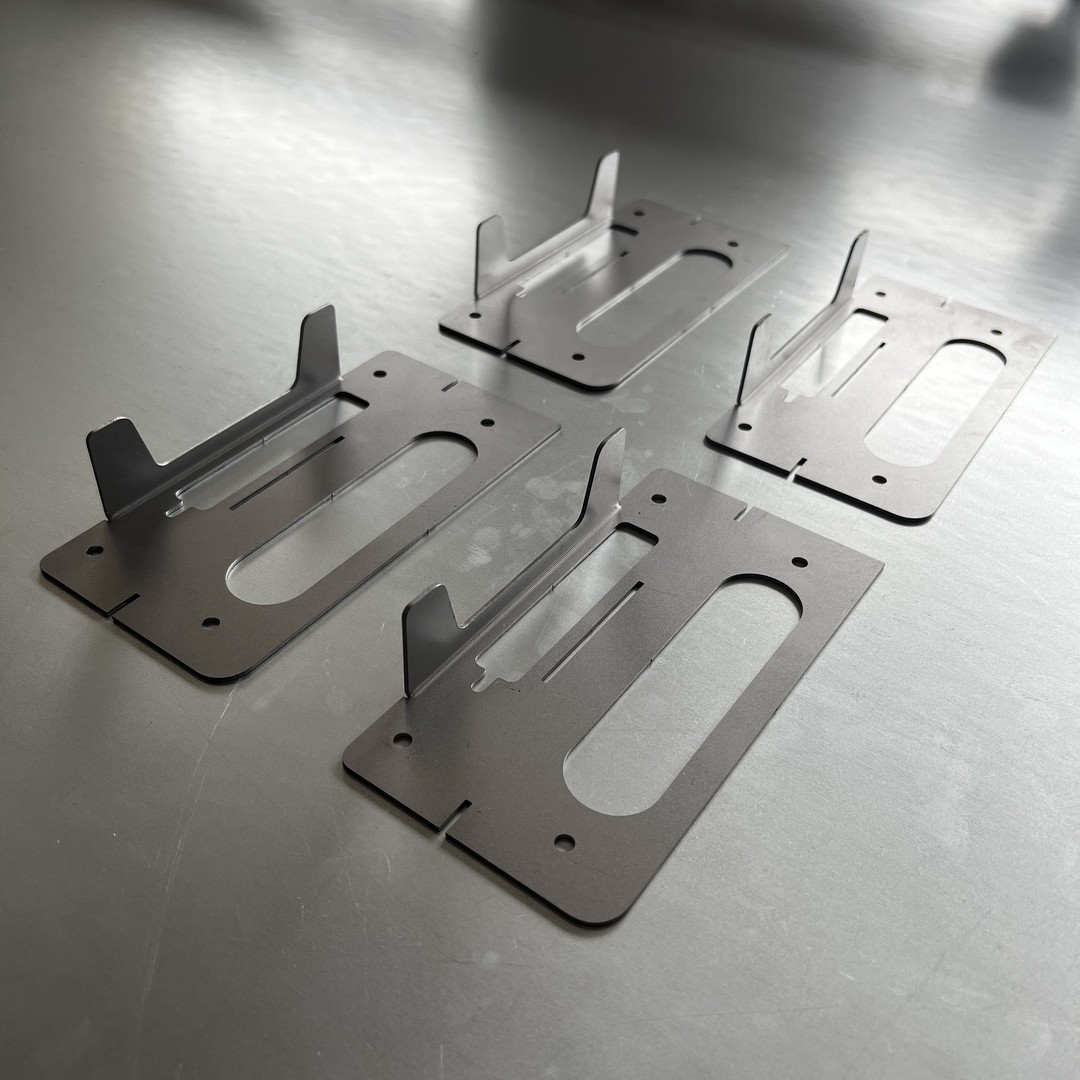

CNC punch cutting and product self inspection:

After selecting the appropriate materials according to the drawing requirements, we will perform CNC punch cutting, and the operator will polish and stamp the connection points of the semi-finished products formed by CNC stamping and remove burrs from the edges of the workpiece.

Sheet metal part roduct self inspection

1. Confirm the size of the first sample with CAD picture, the hole distance tolerance is within 10c.

2. Continue to work after confirming the first sample.

3. The surface must be no nick, indentation, or more.

4. The rag and burrs can not be big (Follow the standard of the sample.)

5. The junction can't be loose.

6. High required workpiece and technology standard, require milling junction or twisting hole.

7. Twisting hole must be round, four sides are no rag so that It can prevent your hands from being stepped.

YISHANG can bend circular and square pipes of different shapes according to customer requirements.

If you want to get free samples, please contact us!

CNC bending processing and quality inspection:

This product undergoes CNC punching and cutting before undergoing CNC bending processing.

Quality inspection requirements for CNC bending:

The angle tolerance is within 50c

2. The length and width tolerance are within 20c

3. The surface must be no nick, indentation or

Shadow

4. Seamless and straight are required when assembling the module, the position of the hole is consistent.