SHEET METAL FABRICATION CAPABILITIES |

| Name | Factory Direct Professional Sheet Metal Fabrication Aluminum Laser Cutting Service |

| General Capabilities | Manufacturing as per design drawings

OEM (Original Equipment Manufacturer) |

| Drawing Format | PRO-E, Auto CAD, Solid Works, UG, CAD / CAM / CAE, PDF |

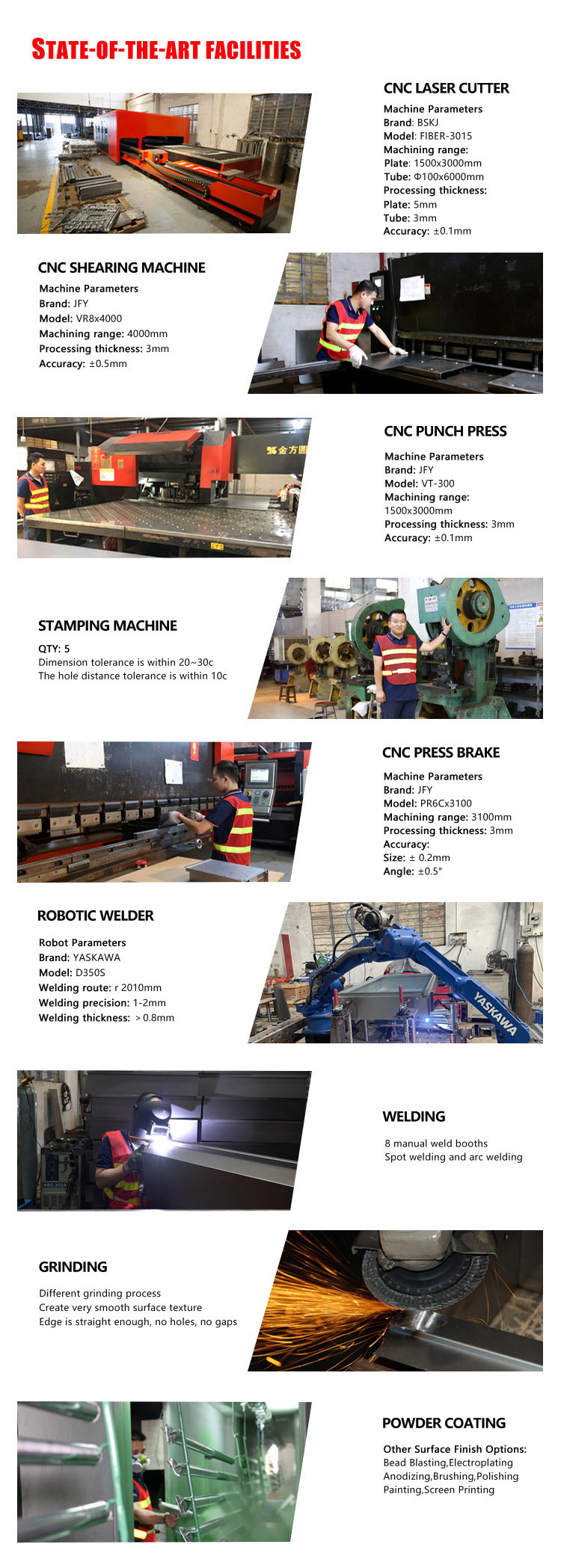

| Automation Capabilities | CNC / Manual / Robotic Load / Unload |

| Welding Process | MIG / TIG / Arc / Stick |

| Fabrication Process | Laser Cutting / Folding / Forming / Punching

Welding / Painting / Powder Coating

Shearing / Stamping/ Polishing |

| Materials Used | AL1060, AL6061, AL6061, AL5052

Steel, mild steel, SPCC

SS201, SS303, SS304, SS316, SS316L

Galvanized sheet

Special requests |

Gauge Size / Thickness

(Laser) | 25mm Max Carbon Steel

30mm Max Stainless Steel & Aluminum |

| Logo | Screen printing, laser marking, UV printing |

| Surface Finish | Powder coating, bead blasting, anodizing, electroplating, polishing, brushing, painting, screen printing, etc |

| Industry Standard | ISO 9001: 2015 |

| Sheet Metal Products | Brackets / Enclosures / Sheet metal parts / Frames/Cabinets

Decorative screen / Stamping parts / Panels / Covers |