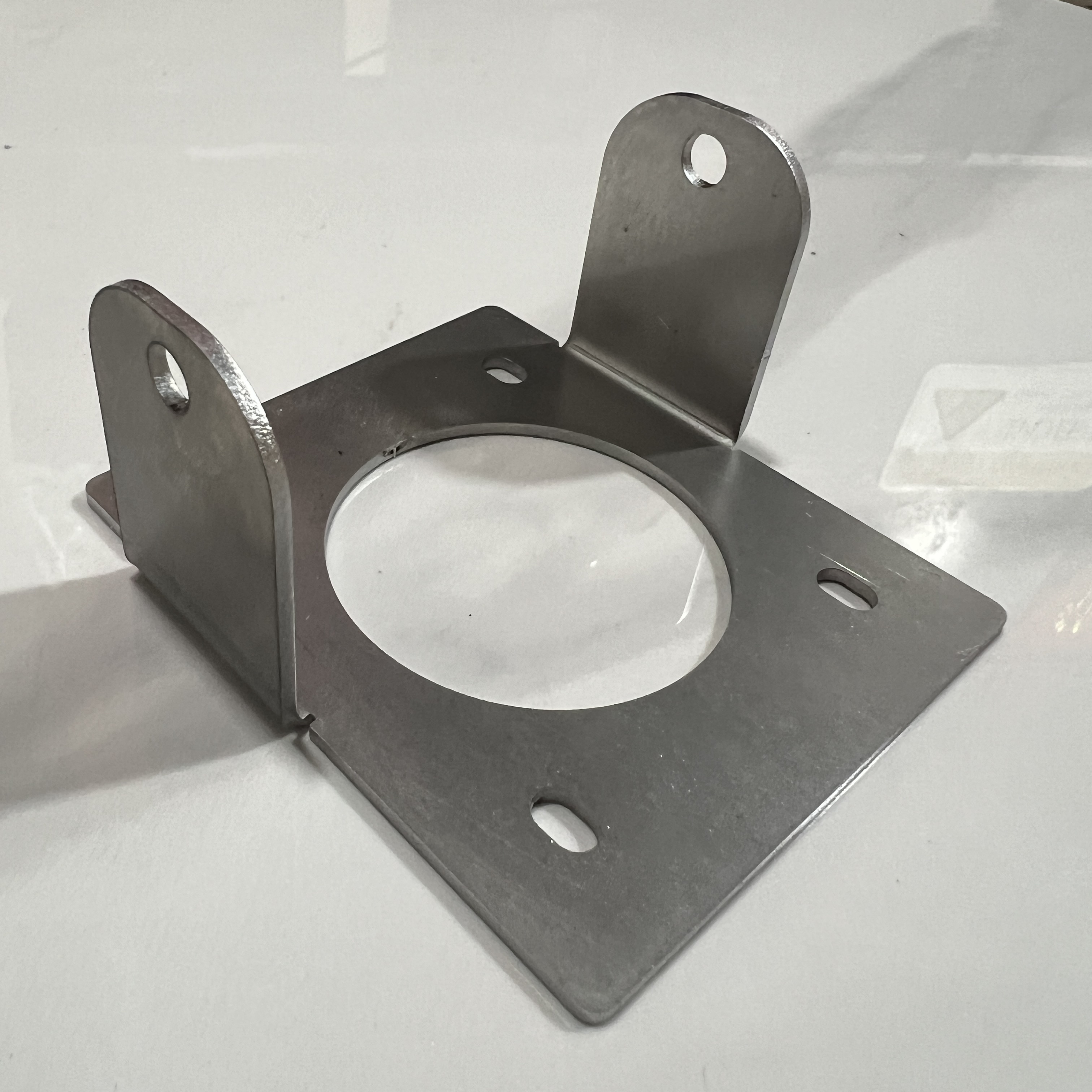

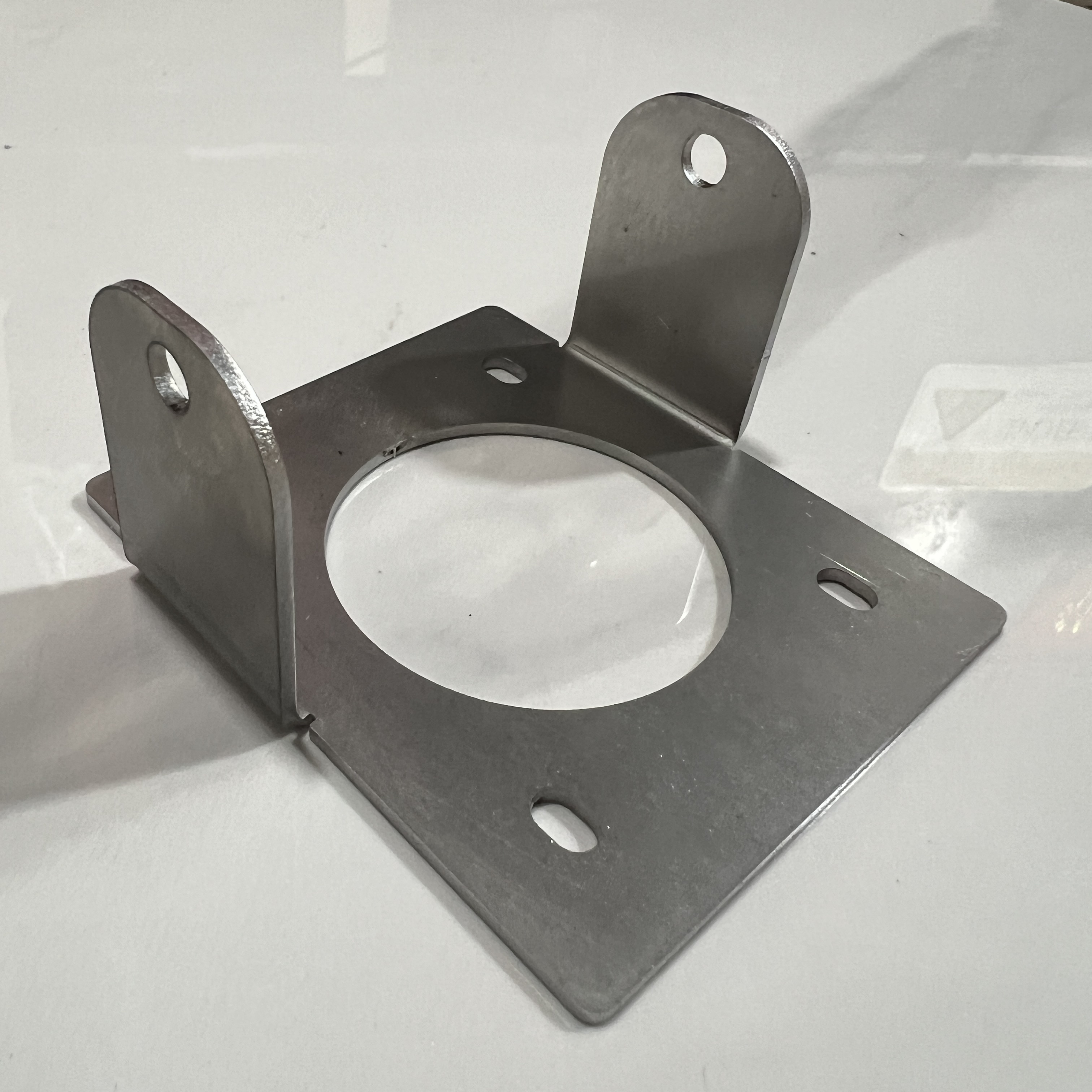

ISO9001 Certified Steel Sheet Metal Processing Forming Sheet Metal Working Parts

| Product name | ISO9001 Certified Steel Sheet Metal Processing Forming Sheet Metal Working Parts |

| Production Progresses | Purchasing raw material / do Inspection on raw material/ make mould/Make samples / Inspection samples/ Sample approvel by customer / Mass production/ Surface finishing/ Packing /Delivery. |

| Tolerance | 0.8~2.0 mm |

| Material selection | Steel,Stainless Steel,Brass,Copper,Aluminum,etc. Mainly Material used as below; 1)Aluminum: 6061,6063,7075,6082 2)Stainless steel: SUS303,SUS304,SUS316L,SUS430 3)Steel: SPCC,SECC,SGCC and ect |

| Surface Treatment | Heat treatment /Mirror Polishing/Electronic Polishing / (Zinc, nickel, chrome, tin, brass, gold, silver, titanium) Plating / Electrophoresis / Black Oxide / Hot-dip galvanizing / Powder Coating / Paint Coating / Blasting / Shot Blasting / Bead Basting / Anodizing / Phosphating / PAD Printing / Laser etching / Dacromet Coating / Enamel. |

| Payment terms | TT |

| Packing Detail | nner Packing: PE bag / EPE Foam Packing / Anti-Rust Paper Packing / Blister / SMT / Vacuum Packing / Plastic Box Packing / Color Box Packing.

Outter Packing: Stretch Film Packing / Carton / Pallet / Wood Case or customized |

| Service | OEM/ODM Stamping Service Tooling/Moulds Design and Make Service |

| Drawing Format Accpeted | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

Customer requirements. The CNC laser cutting machines ensure precise and accurate cuts, resulting in high-quality sheet metal working parts.

Our sheet metal working parts are made from 1.0-2.0mm thick stainless steel or carbon steel plates, providing durability and strength. The use of CNC laser cutting technology allows us to cut and shape the metal into any desired shape, catering to the specific needs of our customers.

With our state-of-the-art CNC laser cutting machines, we can create intricate and complex designs with ease. Whether simple geometric shapes or intricate patterns, our machines deliver exceptional precision and consistency.

The laser-cutting process ensures clean and smooth edges, eliminating the need for additional finishing or polishing. This not only saves time but also ensures a professional and polished look for the final product.

Our sheet metal working parts are suitable for various applications, including automotive, aerospace, electronics, and more. The versatility of our products makes them an ideal choice for various industries.

At Yishang, we prioritize quality and customer satisfaction. Our team of skilled professionals ensures that each sheet metal working part meets the highest standards of precision and quality. We are committed to delivering products that exceed our customers' expectations.

Choose Yishang for your sheet metal working part needs and experience the difference between superior quality and exceptional service. Contact us today to discuss your specific requirements and let us provide you with the perfect solution for your project.

FAQ

Q1: Where can I get sheet metal fabrication product & price information?

A: Send us an inquiry e-mail, we will contact you as we receive your mail.

Q2: How long can I get the sample?

A: Depends on your specific items, within 3-7 days is required generally.

Q3: What's kinds of information you need for a quote?

A: Kindly please provide the product drawing in PDF, and will be better you can provide in STEP or IGS.

Q4: what's the payment terms?

A: We accept 50% as payment deposit when the goods are done, we take photos for your check and you then pay the balance.

Q5: How to deliver the goods?

A: We will deliver goods through international freight forwarders such as DHL UPS or federal.

Q6: Are you a trading company or factory?

A: We are direct factory with experienced engineers and employees as well as approximate 4,000 square meters workshop area.

Q7: What shall we do if we do not have drawings?

A: Please send your sample to our factory, then we can copy or provide you better solutions.

Please send us pictures or draftswith dimensions (Length, Height, Width), CAD or 3D file will be made for you if placed order.

Q8: Can we get some samples before mass production?

A: Absolutely,the freight is paid by the customer.

Q9: Will my drawings be safe after sending to you?

A: Yes, we will keep them well and not release to the third party without your permission.

Q10: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with pictures or videos which show the machining progress.