Sheet Metal Fabrication Welding Steel Wall Mounting Metal Brackets

| Product name | Sheet Metal Fabrication Welding Steel Wall Mounting Metal Brackets |

| Production Progresses | Purchasing raw material / do Inspection on raw material/ make mould/Make samples / Inspection samples/ Sample approvel by customer / Mass production/ Surface finishing/ Packing /Delivery. |

| Tolerance | 0.8~2.0 mm |

| Material selection | Steel,Stainless Steel,Brass,Copper,Aluminum,etc. Mainly Material used as below; 1)Aluminum: 6061,6063,7075,6082 2)Stainless steel: SUS303,SUS304,SUS316L,SUS430 3)Steel: SPCC,SECC,SGCC and ect |

| Surface Treatment | Heat treatment /Mirror Polishing/Electronic Polishing / (Zinc, nickel, chrome, tin, brass, gold, silver, titanium) Plating / Electrophoresis / Black Oxide / Hot-dip galvanizing / Powder Coating / Paint Coating / Blasting / Shot Blasting / Bead Basting / Anodizing / Phosphating / PAD Printing / Laser etching / Dacromet Coating / Enamel. |

| Payment terms | TT |

| Packing Detail | nner Packing: PE bag / EPE Foam Packing / Anti-Rust Paper Packing / Blister / SMT / Vacuum Packing / Plastic Box Packing / Color Box Packing.

Outter Packing: Stretch Film Packing / Carton / Pallet / Wood Case or customized |

| Service | OEM/ODM Stamping Service Tooling/Moulds Design and Make Service |

| Drawing Format Accpeted | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

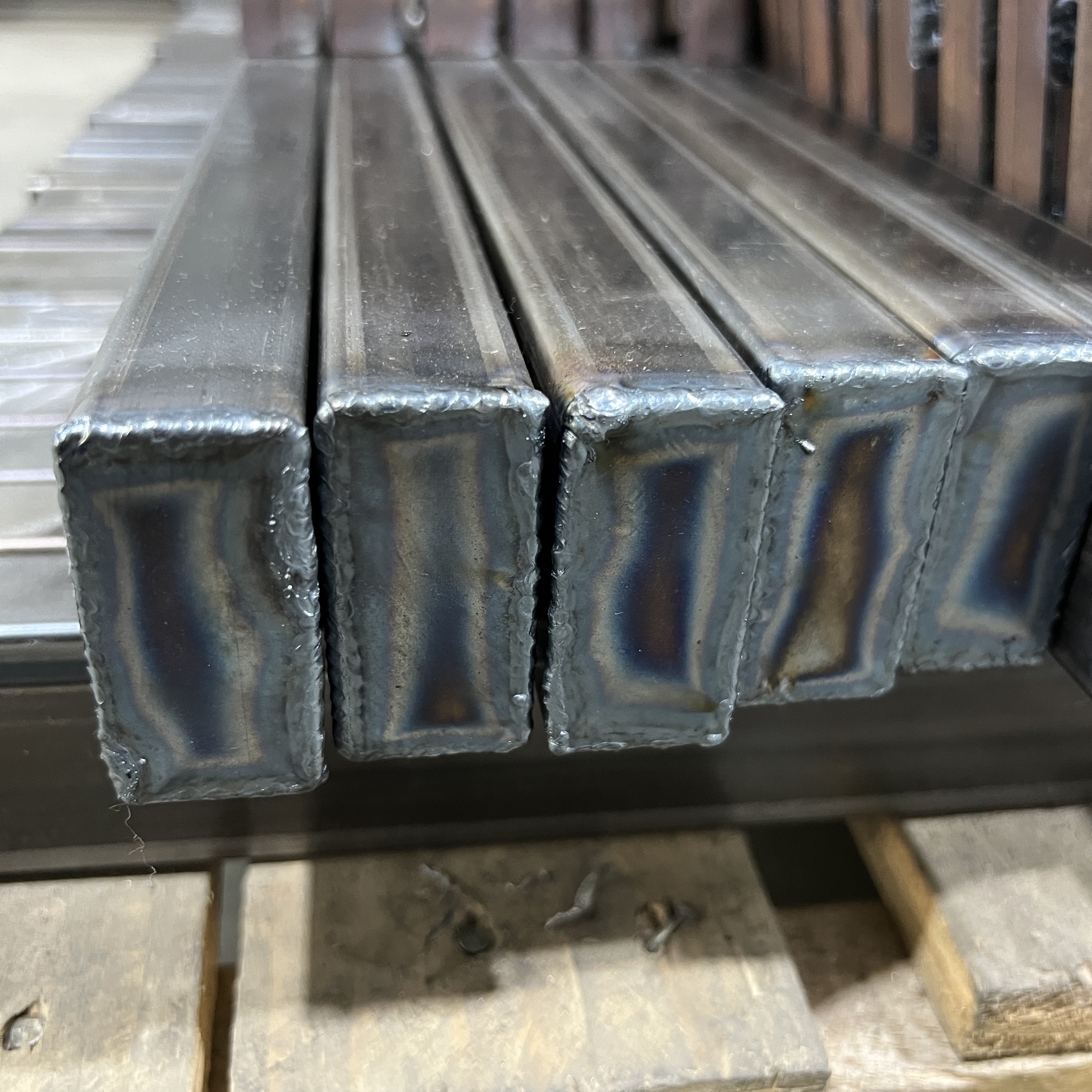

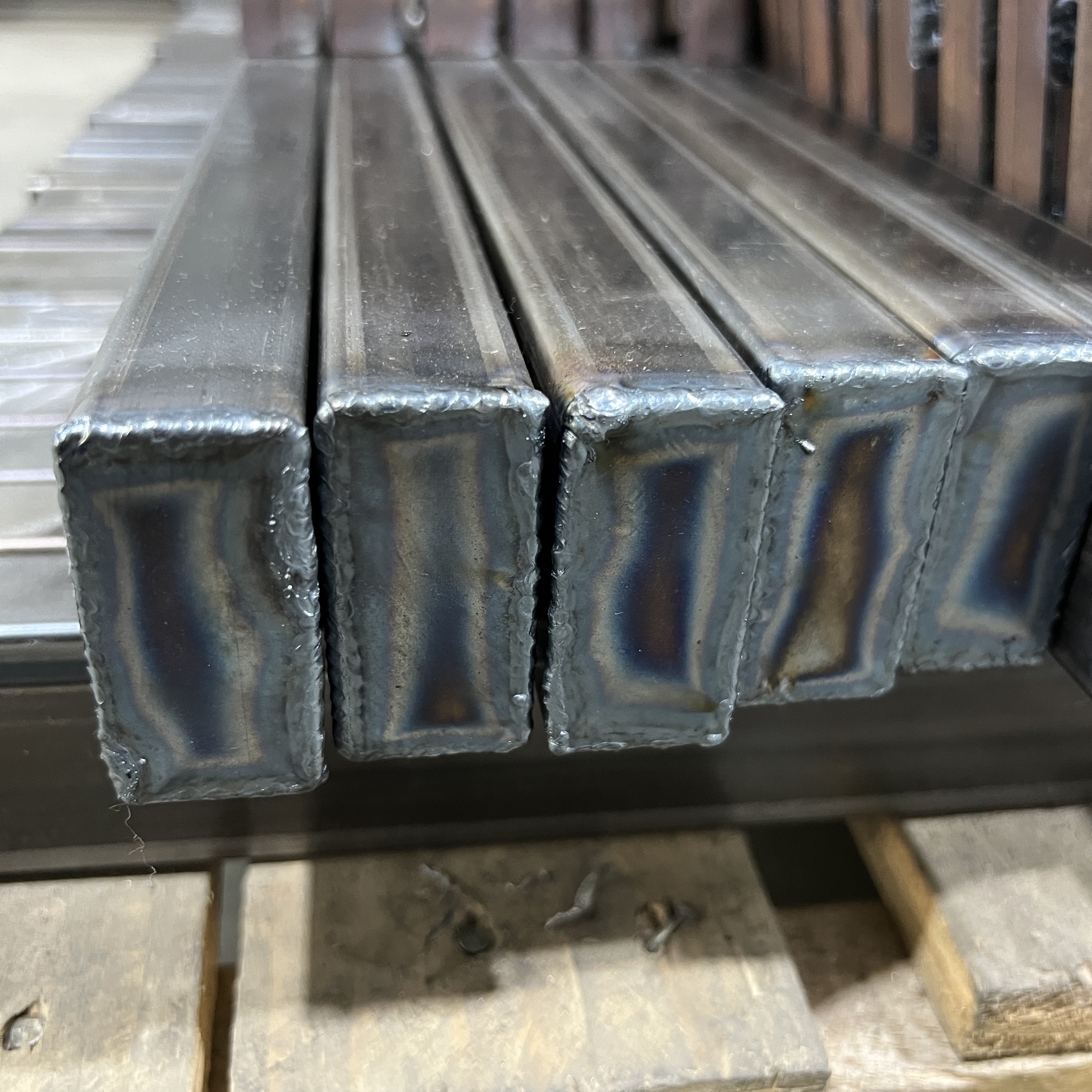

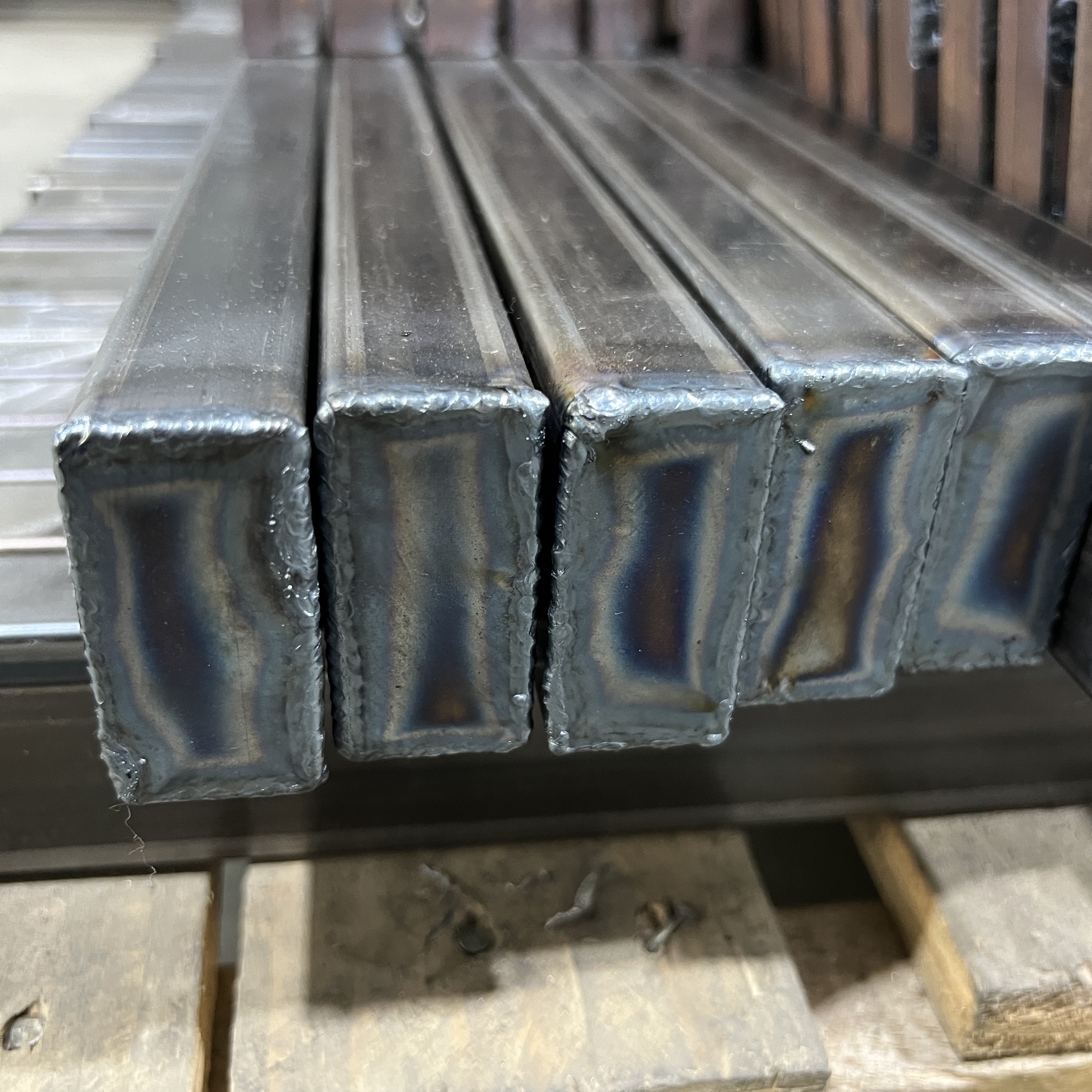

Select 1.2mm iron plate and metal tube, use CNC punching machine bending equipment, and customize a rapid forming steel structure frame.

Manual argon arc welding is used to process and shape the product, and finally, polishing is selected to remove the surface of the product, as shown in the left figure.

If you have the same project that needs customization, please contact us

As shown in the diagram, the steel structure frame buckle is installed according to local display.

FAQ

Q1: Where can I get sheet metal fabrication product & price information?

A: Send us an inquiry e-mail, we will contact you as we receive your mail.

Q2: How long can I get the sample?

A: Depends on your specific items, within 3-7 days is required generally.

Q3: What's kinds of information you need for a quote?

A: Kindly please provide the product drawing in PDF, and will be better you can provide in STEP or IGS.

Q4: what's the payment terms?

A: We accept 50% as payment deposit when the goods are done, we take photos for your check and you then pay the balance.

Q5: How to deliver the goods?

A: We will deliver goods through international freight forwarders such as DHL UPS or federal.

Q6: Are you a trading company or factory?

A: We are direct factory with experienced engineers and employees as well as approximate 4,000 square meters workshop area.

Q7: What shall we do if we do not have drawings?

A: Please send your sample to our factory, then we can copy or provide you better solutions.

Please send us pictures or draftswith dimensions (Length, Height, Width), CAD or 3D file will be made for you if placed order.

Q8: Can we get some samples before mass production?

A: Absolutely,the freight is paid by the customer.

Q9: Will my drawings be safe after sending to you?

A: Yes, we will keep them well and not release to the third party without your permission.

Q10: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with pictures or videos which show the machining progress.