Sheet Metal Enclosure ARC Welding Service

Sheet Metal Enclosure ARC Welding Service

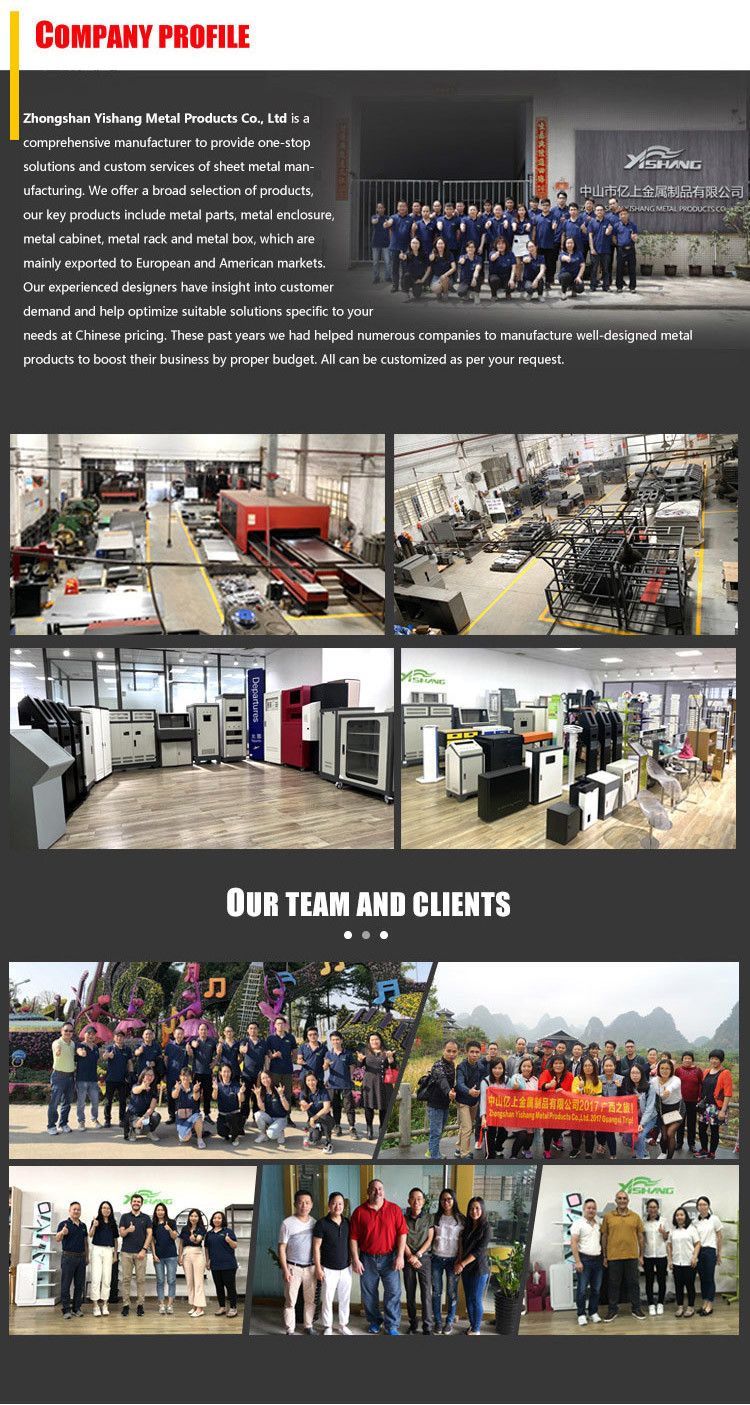

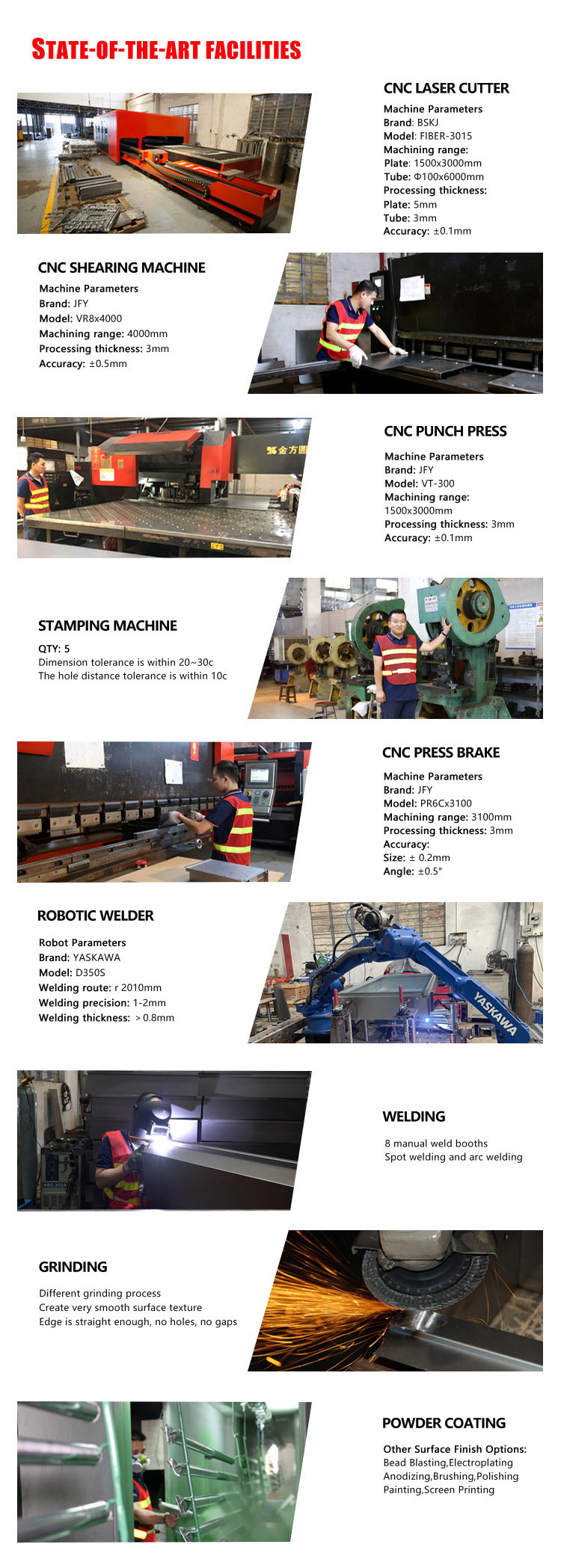

We use a arc to weld and process this metal shell stainless steel panel.

Quality inspection requirements after laser welding:

1. The radial position cannot be destroyed

2. Welding spot is straight both left and right side

The dimension of welding spots follows the drawing standard

3. Surface is without holes, gap and cannot be out of shape and bubbling

4. Surface can be smooth or TIG welding, following the drawing standard

5. The advantages are stable quality, high capacity and simple operation

If you want to get free samples, please contact us!

Stainless steel panel polishing and processing service

We use a polishing machine to polish the welding position of the product.

Quality inspection requirements for polishing:

1. The plane is smooth enough, no shadow, no holes, no gaps, no seams

2. The inner angle follows drawing standard

3. The outer corner surface needs to polarize the angle

4. Straight edge is straight enough, no holes, no gaps (the width is not more than 20mm)

Sheet Metal Enclosure ARC Welding Service

Sheet Metal Enclosure ARC Welding Service