| SHEET METAL FABRICATION CAPABILITIES |

| General Capabilities | Manufacturing Based On Drawing |

| OEM (Original Equipment Manufacturer) |

| Drawing Formats | PRO-E, Auto CAD, Solid Works, UG, CAD / CAM / CAE, PDF |

| Automation Capabilities | CNC / Manual / Robotic Load / Unload |

| Fabrication Process | Laser Cutting / Folding / Forming / Punching | Welding / Painting / Powder Coating |

| Rolling / Shearing / Stamping | Plating / Hardware Insertion/Assembly |

| Welding Process | MIG / TIG / Arc / Stick |

| Materials Used | Aluminum / Stainless steel | Galvanized steel |

| Cold rolled steel / Hot rolled steel | Special requests |

| Gauge Size / Thickness (Laser) | 25mm Max Carbon Steel |

| 30mm Max Stainless Steel & Aluminum |

| Industry Standard | ISO 9001: 2015 |

| Sheet Metal Product | Brackets / Enclosures / Sheet metal parts / Frames | Decorative screen / Stamping parts / Panels / Covers |

| Industry Focus | Agricultural / Auto / Truck / Transportation | Military / Oil Field / Packaging |

| Chemical / Machine Tool/Medical | Pharmaceutical |

| Central:

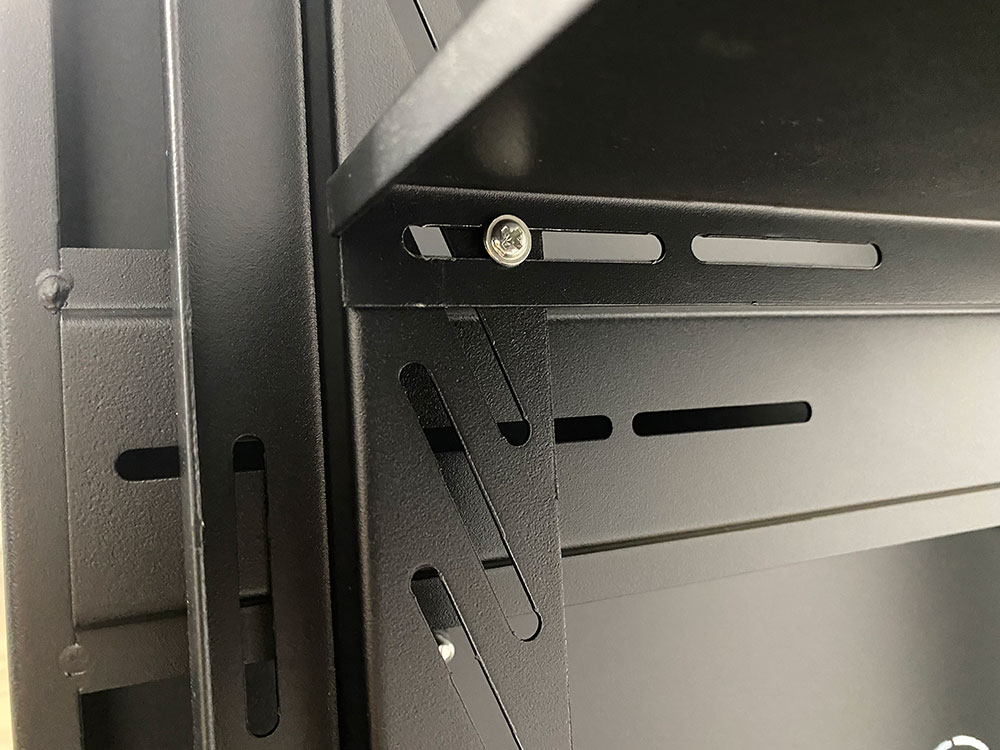

Built-in shelf: Shelves can be long and adjustable columns, and the operator can adjust different heights according to the equipment Placed inside the box.

Front and rear side panels:

The buckle installation method is adopted to maintain the beauty and simplicity of the network cabinet.

Front and rear door panels: double-opening design is adopted to facilitate the operator to view the internal data of the network cabinet. The pull-hand door lock is simple and convenient to switch. |

| Accessories:

There is a white integrated air conditioning distribution box on the outside, which can be detached or fixed for trial installation.

|

| Bottom

Casters: Use universal casters, with or without brakes.

Customers only need to provide the load-bearing data of the network cabinet, and we will configure suitable casters for you.

|