Why 1055 Carbon Steel Matters for Industrial Buyers

1055 carbon steel is a medium-carbon material prized in industrial procurement for its ability to deliver dependable hardness without the price tag of high-alloy steels. It strikes a rare balance between strength, wear resistance, and cost-efficiency—ideal for manufacturers producing mid- to high-volume parts.

In today’s supply-driven procurement landscape, overseas buyers are seeking materials that simplify processing, reduce machining downtime, and allow predictable performance across batches. 1055 carbon steel fits these priorities especially well in sectors like tools, automotive, and agriculture, where durability meets repeatability.

This article explores how 1055 carbon steel aligns with fabrication demands, mechanical tolerances, and sourcing decisions that procurement teams must make daily.

What Is 1055 Carbon Steel Really Offering for B2B Procurement?

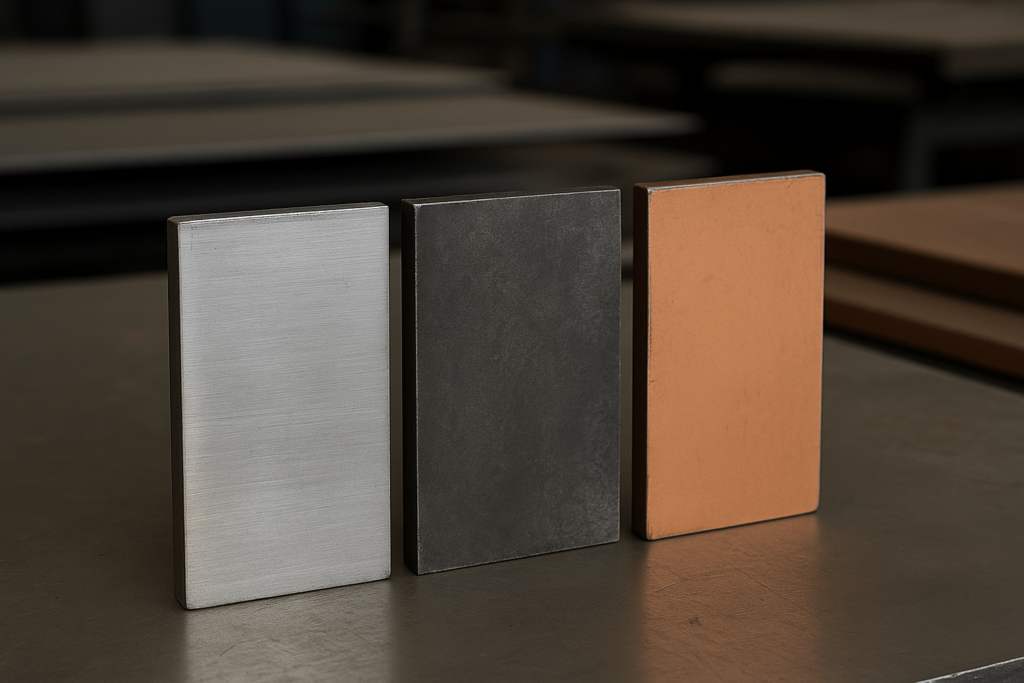

1055 carbon steel belongs to the medium-carbon steel family, containing approximately 0.55% carbon and 0.75% manganese. For buyers, this composition enables a balance of wear resistance, moderate structural load capacity, and early-stage fabrication flexibility.

It stands more robust than 1018 or 1040, yet remains more adaptable than high-carbon options like 1095. For procurement teams managing high-throughput lines or part replication, this means fewer breakdowns during forming, less downtime in CNC machining, and consistent quality across batches.

From a metallurgical perspective, its untreated ferrite-pearlite structure transforms into fine-grained martensite after heat treatment. This characteristic makes 1055 ideal for wear-prone components and edge-retaining geometries.

Comparative View for Sourcing Decisions

| Steel Grade | Carbon Content | Post-Treatment Hardness (HRC) | Common Use Case |

|---|---|---|---|

| 1045 | ~0.45% | 50–55 | Shafts, gear blanks |

| 1055 | ~0.55% | 55–62 | Blades, hand tools |

| 1095 | ~0.95% | 60–66 | Precision cutters |

For global distributors or OEM clients managing steel sheet metal material in multiple SKUs, 1055’s stock stability and low alloy variability contribute to lean inventory and simplified procurement.

Heat Treatment: Engineering Performance into the Supply Chain

The performance transformation of 1055 lies in heat treatment. It responds consistently to austenitizing (800–840°C) and oil quenching, minimizing risk of cracking. Subsequent tempering fine-tunes its hardness-to-toughness ratio for specific functional demands.

| Tempering Temp (°C) | Approx. Hardness (HRC) | Target Use |

| 200–300 | 60–62 | Cutting tools, shear blades |

| 400–500 | 55–58 | Springs, brackets, tool frames |

| 600–650 | 48–52 | Impact tools, hammers |

This heat-treat adaptability enables one base material to meet various performance specs, ideal for clients consolidating part categories under one steel grade to control cost and simplify logistics.

Mechanical Properties and Buyer Engineering Priorities

Properly treated 1055 achieves 800–1,000 MPa tensile strength and 600–700 MPa yield strength. Its moderate modulus of elasticity supports structural resilience in load-bearing tools and repetitive-impact components.

Compared to 4140 or 4130 alloy steel, 1055 avoids dependence on additional alloying elements and associated price volatility. It still delivers acceptable impact strength and fatigue life for parts under dynamic stress.

Clients using laser cut steel signs, pressed hardware, or formed spring plates value its machining consistency. For steel coating strategies, powder coated steel or phosphate finishes complement mechanical endurance with anti-corrosive resilience.

Application Logic: Where 1055 Delivers the Most Value

Knives, Blades, and Tools

1055 is widely chosen for tools requiring edge stability and mid-range shock resistance. Machetes, pruning knives, or shear components benefit from its martensitic hardness post-treatment. Powder coating steel or black oxide finishing improves corrosion resistance.

Case Example: A North American tool importer working with YISHANG transitioned from 1045 to 1055 carbon steel in their line of agricultural machete blades. This shift resulted in a 28% decrease in material breakage rates and reduced regrinding time by over 30%, improving both lifecycle performance and batch consistency.

Agricultural and Construction Parts

Parts like hoe blades or structural stiffeners fabricated from 1055 outperform mild steel under impact. Especially where terrain variability or soil resistance causes bending or cracking, 1055 provides durability without cost excess.

Automotive and General Hardware

Used in brackets, levers, or suspension retainers, 1055 meets tolerances and durability requirements without entering the high-cost tier of alloy steels. Combined with powder coated finishes or galvanized surfaces, it supports outdoor or underbody use.

Trade-Offs and Engineering Cautions

1055 lacks inherent corrosion protection. Without powder coat steel treatment, oxidation risk rises in humid zones. Buyers deploying parts outdoors or in semi-marine conditions should specify black oxide, phosphate, or powder coating galvanised steel options.

Its weldability is moderate—acceptable when pre-heated and tempered post-weld. Robotic or high-speed welding lines may need adaptation, making 1055 less ideal where speed outweighs material cost.

Finally, 1055’s mechanical profile drops significantly at continuous temperatures over 300°C. Buyers needing heat resistance should evaluate 304 stainless steel temperature rating or use alloy alternatives.

Strategic Fit for Industrial Buyers

For buyers evaluating steel sheet processing and medium-duty hardware fabrication, 1055 offers an optimal balance between material cost, mechanical reliability, and process repeatability. It’s not a stainless steel, but it is dependable, uniform, and ready for OEM conversion.

In BOM consolidation or SKU reduction strategies, one steel grade capable of multiple property profiles (via heat treatment) enables cost savings and simplifies global sourcing.

Ordering 1055 Carbon Steel Parts with YISHANG

Our procurement process follows a simple framework:

Receive part drawing or specifications

Confirm stress profile and end-use conditions

Recommend finish (powder coat, oxide, phosphate)

Submit quote with lead time

Prototype verification and batch production

We provide engineering insights into whether alloy steel vs. carbon steel is better for your needs and optimize surface treatment based on mechanical exposure and aesthetic targets.

FAQs

Is 1055 suitable for outdoor products?

Yes, with proper coating (e.g., powder coating galvanised steel or black oxide).

Can it replace 4140 steel?

In medium-stress, low-corrosion roles, yes. For high-load/high-heat, 4140 remains superior.

What’s its machinability rating?

Moderate before hardening; harder states require coated carbide tools.

Does it suit structural applications?

Yes, for medium-load support, brackets, frames, and impact-facing elements.

Why choose YISHANG for 1055 components?

Because we offer vertically integrated forming, machining, coating, and assembly tailored to your supply chain.