Why Thickness Matters in Aluminum Buying

For OEM aluminum buyers, 16ga directly influences bend performance, finish uniformity, and shipping efficiency—key cost and function drivers in industrial sheet metal use.

It balances well between flexibility and rigidity, making it suitable for processes like bending, powder coat aluminium, and aluminum CNC service. That’s why many suppliers and manufacturers standardize it for consistent results.

Understanding 16 Gauge Aluminum in Practical Terms

While gauge is a familiar term in sheet metal, its interpretation differs across materials. In aluminum, 16 gauge refers to 0.0508 inches (1.29 mm), but this doesn’t align with the same gauge in steel or stainless.

| Material | Thickness (in) | Thickness (mm) |

|---|---|---|

| 16ga Aluminum | 0.0508 | 1.29 |

| 16ga Steel (CR) | 0.0598 | 1.52 |

| 16ga Stainless Steel | 0.0625 | 1.59 |

Why does it matter? Procurement mistakes caused by gauge misinterpretation can lead to costly rework, especially in OEM applications involving tight fits, CNC-drilled parts, or pre-anodized sheets.

According to ASTM B209, the thickness tolerance for aluminum sheets in this range may vary by ±0.10 mm. That margin becomes critical when integrating with laser-cut aluminum brackets or custom-finished panels requiring aluminum anodizing or alodine chromate conversion coating.

Why Aluminum Has Its Own Gauge—and Why It Matters to Buyers

Unique Measurement Origins: Unlike ferrous metals, aluminum’s gauge scale developed independently due to its distinct density and fabrication behavior. This discrepancy becomes especially important when aluminum parts are integrated with stainless or galvanized steel in hybrid assemblies.

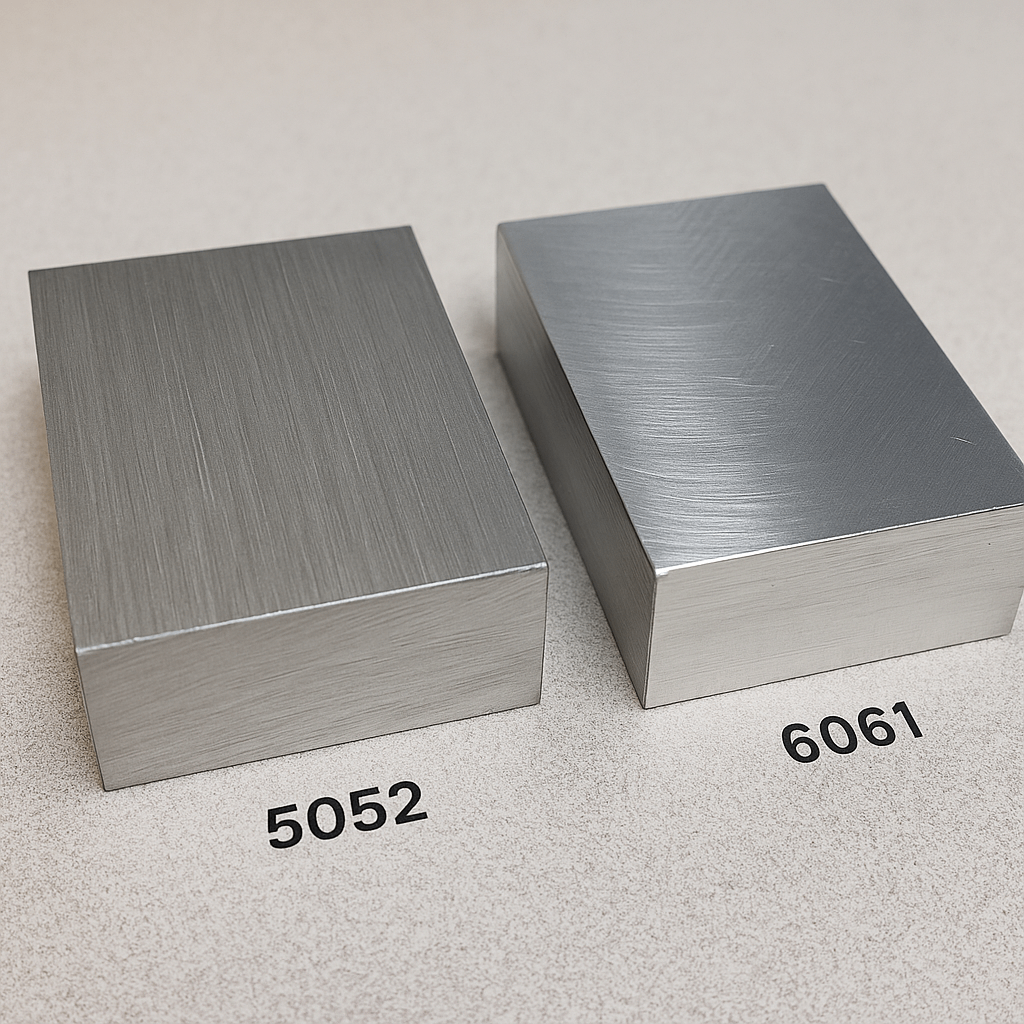

Alloy Selection Impact: The choice of alloy and temper within 16ga is another strategic decision. For example, 6061 aluminum hardness differs substantially from that of 5052. While the former offers higher rigidity, it’s less forgiving in deep bending or rapid stamping operations.

Finishing Considerations: Buyers sourcing components for aluminum CNC service or aluminum powder coating must specify not only gauge but also alloy (e.g., 5052-H32 or 6061-T6) and finishing tolerance. Surface treatments like aluminum anodizing or powder coat aluminium significantly impact final thickness and fit.

How 16 Gauge Aluminum Supports Production Agility

Many procurement teams favor 16ga aluminum due to its superior adaptability in production. It’s light enough for easy transport yet strong enough to avoid flex or deflection under moderate load. More importantly, it suits high-throughput operations in aluminum fabrication shops.

Use cases where 16ga dominates include:

Retail display systems: Ideal for folded, powder coated aluminium panels

Sheet metal enclosures: Particularly in vending or kiosk applications using 16 gauge aluminum for kiosks

Aluminum extrusion enclosures: Integrates cleanly with 2020 aluminum extrusion frameworks

This gauge also allows for consistent surface finish in aluminum powder coat processes—its thin profile reduces risks like orange peel and edge pooling, common with thicker substrates. For applications such as retail panels or precision signage, 16ga offers the best thickness for aluminum signage without overengineering the structure.

Fabrication Realities: What to Expect from 16ga Aluminum

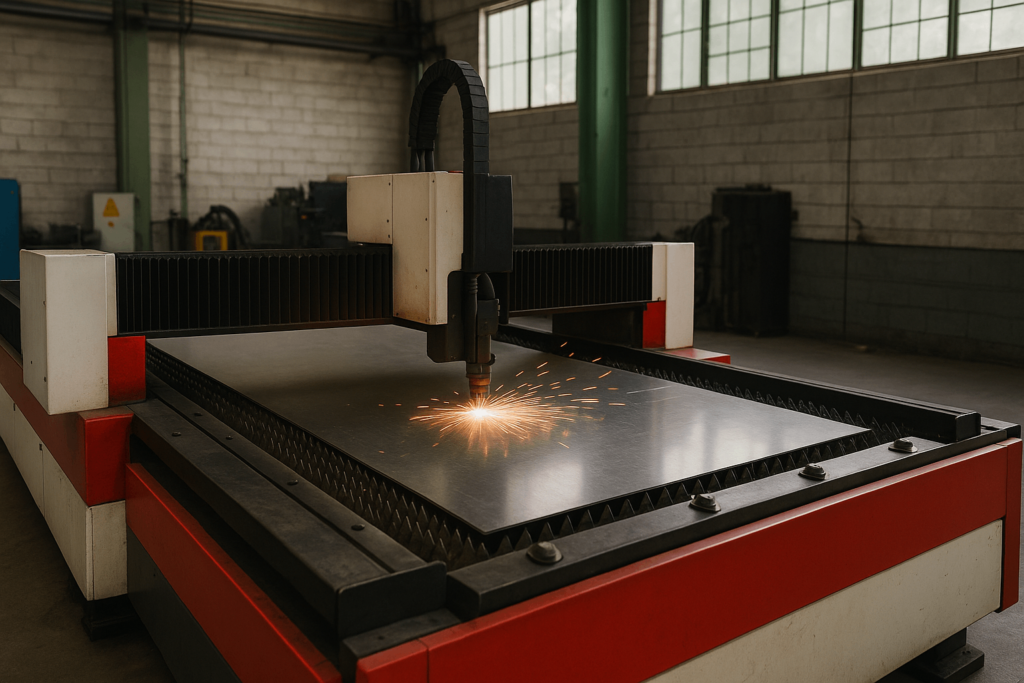

Many aluminum fabrication shops consider 16ga the optimal sheet gauge for aluminum powder coating finish due to its ability to maintain flatness while avoiding excessive material buildup. It’s equally ideal in laser cutting services, where clean separation is critical.

Aluminum fabricators report that 16ga is optimal for both manual and automated systems. During laser cutting, its thickness supports clean separation with minimal slag. For alu anodized components, it’s thin enough for uniform color penetration.

In bending, results vary by alloy:

5052-H32: Recommended minimum bend radius is 1.5× sheet thickness

6061-T6: Requires larger radius (>2.5× thickness) or edge reliefs to prevent cracking

Welding 16ga aluminum is relatively straightforward using TIG or MIG methods. But downstream finishing—such as aluminum anodizing colors or alodine coating—should be applied post-weld to avoid inconsistencies.

When machining aluminum CNC parts, 16ga offers sufficient depth for tapping, riveting, and precise hole tolerances. It also suits projects where best thickness for aluminum signage is required for durability without unnecessary weight.

Avoid These Missteps in Aluminum Gauge Procurement

Common procurement pitfalls that impact lead time and part quality:

Misreading Gauge Charts: Aluminum sheet gauge chart data differs from steel. Always verify dimensions in mm/inches, not just gauge.

Overlooking Post-Finish Growth: Finishes like powder coated aluminium can increase thickness by 0.1–0.2 mm. This may exceed design tolerances if not accounted for, especially when dealing with sheet metal thickness for powder coating process.

Confusing Thickness with Strength: A thicker sheet doesn’t always mean higher strength. For unsupported sections, the aluminum alloy and structural design dictate performance more than gauge alone.

Why 16ga Helps Meet Strategic Sourcing Goals

For wholesalers and OEMs sourcing custom 16 gauge aluminum sheet for OEM buyers, the material offers high utility in applications such as vending systems, paneling, and outdoor displays.

This gauge is also favored when choosing the best aluminum thickness for vending machine panels—strong enough for protection, thin enough for lightweight shipping.

For wholesalers and systems integrators, sourcing 16 gauge aluminum for kiosks or custom enclosures enables:

Lower shipping weight with maintained structural integrity

Streamlined aluminum CNC projects thanks to predictable formability

Cross-market alignment between retail displays, kiosk housings, and signage substrates

For example, one YISHANG client transitioned from 14ga steel to 16ga 5052 aluminum in housing production. This change reduced individual unit weight by 1.2 kg and saved 19% on material cost—while enhancing surface compatibility with aluminum anodizing and powder coat aluminium.

16ga is readily available in standard formats from most aluminium sheet metal fabricators, ensuring global sourcing continuity.

Technical Snapshot: Sheet Sizes, Alloys & Usage

| Sheet Size | Alloy | Est. Weight | Ideal Applications |

| 4′ x 8′ | 5052-H32 | ~21.6 lbs | Powder coated panels, kiosk systems |

| 4′ x 10′ | 6061-T6 | ~27.0 lbs | Vending enclosures, flat-pack frames |

| 2′ x 4′ | 1100-H14 | ~5.4 lbs | Custom branding panels, curved facades |

Process Reminders:

Laser Cutting: Use fiber-optic heads for clean separation

Bending: Observe minimum radius by alloy

Anodizing/Alodine: Clean with compatible agents to ensure finish uniformity

Buyer FAQs: Technical Answers to Real-World Questions

What is the minimum order quantity (MOQ) for 16ga aluminum components?

Our MOQ typically depends on customization level and fabrication process, but starts from 100 units for standard panels.

What certifications do your aluminum sheets comply with?

YISHANG supports RoHS and ISO 9001 standards. Material certification and mill test reports can be provided upon request.

Is 16ga aluminum suitable for exterior use?

Yes, particularly when combined with 5052-H32 alloy and protective coatings such as aluminum anodizing or alodine chromate conversion. These treatments enhance corrosion resistance in marine and outdoor environments.

Will 16ga aluminum fit existing extrusion systems?

Yes. It’s commonly used with extrusion systems like 2020 aluminum extrusion or 80/20 components. Compatibility depends on confirming panel thickness post-finishing.

Can YISHANG customize 16ga solutions?

Absolutely. As a seasoned aluminium laser cutting and aluminum CNC service provider, YISHANG supports both ODM and OEM batch orders with full pre-treatment and packaging solutions.

Final Word: Why 16ga Makes Strategic Sense

For OEM buyers and wholesale fabricators, 16 gauge aluminum strikes the right balance between form, function, and cost-efficiency. It performs well across key fabrication processes—whether it’s bending, CNC machining, or anodizing.

Over 60% of our OEM panel customers standardize 16ga sheets across multiple product lines, citing reliability and finish quality. Lightweight without sacrificing strength, it keeps shipping costs down and productivity up.

YISHANG supplies 16ga aluminum in ready-to-ship and custom formats, optimized for international orders and industry standards. Let us help you specify and scale your aluminum sourcing with confidence.