Introduction: Why Material Selection Matters in Industrial Procurement

For industrial procurement professionals, selecting the right steel alloy means balancing mechanical performance, production compatibility, cost-efficiency, and delivery timelines. Two of the most common chromium-molybdenum steels in global sourcing are 4130 and 4140. Though both fall under low-alloy, high-strength classifications, they are far from interchangeable.

This guide provides a practical, production-focused comparison of 4130 and 4140, based on real fabrication use cases and frequent supplier inquiries. At YISHANG, we support OEMs and industrial buyers in selecting and machining these materials across sectors like automotive components, agricultural tooling, energy systems, and structural fabrication. What follows is a sourcing-oriented guide designed to reduce selection risk and optimize your supply strategy.

Composition Differences: 4130 vs 4140 Steel Chemistry in Context

4130 steel, formally classified as AISI 4130 or ASTM A519, contains approximately 0.30% carbon, with chromium and molybdenum enhancing its weldability and moderate strength. Its relatively low carbon content contributes to excellent ductility and machinability, and it’s often used in applications where fabrication and welding are critical. 4130 steel composition also supports excellent fatigue resistance and flexibility during forming.

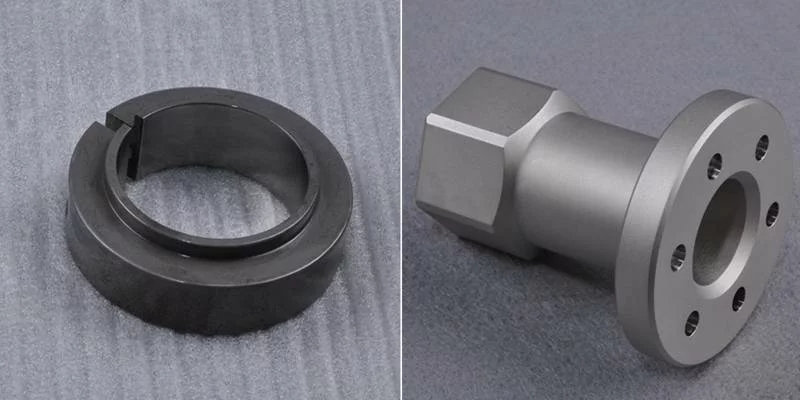

4140 chromoly steel — typically designated as AISI 4140 or ASTM A29 / SAE 4140 — contains around 0.40% carbon. This difference increases tensile strength, deep hardening, and surface durability. It’s well-suited for components like press-fit shafts, tool bodies, and high-torque gears. 4140 steel properties offer better wear life in heavy-load environments.

Procurement teams must understand these distinctions. The increased carbon and alloy content in 4140 also affect weldability, heat treatment complexity, and material cost. 4130 steel supports rapid prototyping and structural welding, while 4140 requires more controlled processing but delivers exceptional mechanical returns.

Mechanical Behavior: Performance Under Load and in the Field

4140 steel tensile strength ranges from 950 to 1100 MPa after heat treatment. Its Rockwell hardness can exceed 50 HRC, making it ideal for wear-resistant tooling and mechanical power transmission. The 4140 yield strength is also higher, offering excellent resistance under static loads. Its fatigue resistance and durability make it a preferred option for press-molded dies and load-bearing joints.

4130 steel tensile strength reaches 560 to 670 MPa (normalized) and up to ~850 MPa when hardened. Its superior elongation (~20–25%) improves shock absorption and cyclic fatigue resistance, making it a prime candidate for UAV frames, robotic assemblies, and aerospace support parts. 4130 steel modulus of elasticity ensures stable performance under oscillating conditions.

| Property | 4130 Steel (AISI 4130) | 4140 Steel (AISI 4140) |

|---|---|---|

| Carbon Content (%) | ~0.30% | ~0.40% |

| Tensile Strength (MPa) | 560–670 (up to 850 HT) | 950–1100 (heat treated) |

| Yield Strength (MPa) | ~460 | ~650–700 |

| Hardness (HRC) | 18–28 (annealed) | 28–32 (annealed), 50+ (HT) |

| Elongation (%) | ~20–25% | ~10–15% |

| Weldability | Excellent | Moderate (requires preheat) |

Processing and Fabrication: Weldability, Machinability, and Heat Treatment

4130 steel welding is straightforward. Minimal preheat is needed, and post-weld cracking is rare. This makes it ideal for aerospace tubing, roll cages, and industrial frame assemblies. Recommended TIG welding parameters include 90–130 amps for 1.6–2.4 mm thickness using ER80S-D2 filler, with interpass temperature control below 150°C.

4140 steel weldability requires more control. Preheating to 200–400°C is essential to prevent hard zones and cracking, particularly for thicker sections above 6 mm. TIG or MIG welding with ER110S-G filler is common. Suggested parameters include 140–180 amps for 3.0 mm+ sections, with post-weld tempering at 540–650°C to restore ductility.

Though machinability is acceptable, 4140 steel hardness (especially in HT condition) necessitates slower feeds, higher rigidity, and sharper tooling. In contrast, 4130 machines well in its annealed state, with smooth chip formation and reduced tool wear.

Both materials respond well to oil quenching and tempering. 4130 heat treatment allows balance between strength and flexibility. 4140 responds to deeper hardening with increased toughness, offering advantages for load-critical components.

Supply Chain and Procurement Considerations

4140 generally commands a 10–20% premium over 4130 due to higher alloying content and processing demands. However, 4140 chrome moly steel may eliminate secondary processes in some use cases — potentially lowering total cost of ownership.

4130 steel offers savings through ease of fabrication, reduced machining costs, and rapid sourcing. Its density, weldability, and adaptability contribute to leaner workflows in projects where speed and design flexibility are key. 4130 material properties also make it a prime choice for batch-based prototyping.

Common Mistakes in Alloy Selection and Fabrication

A European chassis manufacturer used 4140 for a welded frame without proper preheat. Weld failures spiked to 12%. Switching to 4130 resolved the issue.

An industrial client used 4130 for high-load shafts. Premature wear occurred. We recommended switching to 4140 steel with localized induction hardening — improving durability by 400%.

Understanding both alloys’ strengths and limits avoids costly redesigns, downtime, or scrap. Our team provides material-fit consulting early in your RFQ process.

Application Matrix: 4130 vs 4140 Steel by Use Case

| Application Scenario | Recommended Steel |

| Welded tubular structures | 4130 |

| Induction-hardened tool spindles | 4140 |

| Low-volume, adjustable tooling | 4130 |

| Surface-wear-critical dies | 4140 |

| Aerospace-grade framework | 4130 |

| High-precision shafts (pre-hardened) | 4140 |

| Robotic joints and frame links | 4130 |

We offer quick BOM reviews and alloy recommendations based on structural load paths, machining sequences, and weld setups.

FAQ: Buyers’ Most Common Questions About 4130 and 4140 Steel

Q1: Is 4130 easier to weld than 4140?

Yes. 4130 requires little or no preheat, while 4140 needs strict heat control to avoid cracks.

Q2: Can both be heat treated?

Absolutely. 4130 responds best to normalization or tempered cycles, while 4140 is ideal for quench and temper.

Q3: What’s the difference in machinability?

4130 is easier to machine in annealed form. 4140 pre-hardened requires slower feed rates and better tooling.

Q4: Are they interchangeable in all applications?

No. While similar, their mechanical and processing traits make each alloy more suitable for different use cases.

Q5: What are the international equivalents?

4130 ≈ 25CrMo4 (EN); 4140 ≈ 42CrMo4 (EN), 1.7225 grade.

Summary: Choosing Between 4130 and 4140 for Industrial Projects

There’s no one-size-fits-all. 4130 steel is ideal for weldable structures and adaptive manufacturing. 4140 steel excels in high-load, wear-critical parts.

At YISHANG, we guide procurement professionals in selecting the optimal grade, condition, and format for their application. With in-stock inventory, global shipping, and traceable documentation, we simplify the alloy sourcing process.

Looking for a reliable supplier of 4130 or 4140 steel with machining-ready formats and global delivery?

YISHANG offers:

Application-based material recommendations based on your BOM, CAD, or specs

CNC machining, welding, and certified heat treatment under ISO 9001

Global supply chain support with MTC, RoHS, and full traceability

MOQ from 100 pcs, delivered in 7–15 working days