Why Industrial Buyers Are Taking a Second Look at 6062

When evaluating aluminum grades for bulk procurement, most sourcing teams default to 6061 or 7075. These mainstream alloys dominate catalogs, but 6062 aluminum—though lesser known—is earning attention from buyers who prioritize consistency, surface finish, and processing compatibility.

For procurement professionals sourcing materials for high-volume fabrication, anodized finishing, or CNC machining, 6062 helps reduce post-processing variance—cutting defect rates and simplifying downstream quality control. Its stable behavior in production environments reduces processing variables, waste, and downtime—factors that directly affect supply chain predictability and batch quality.

What Exactly Is 6062 Aluminum?

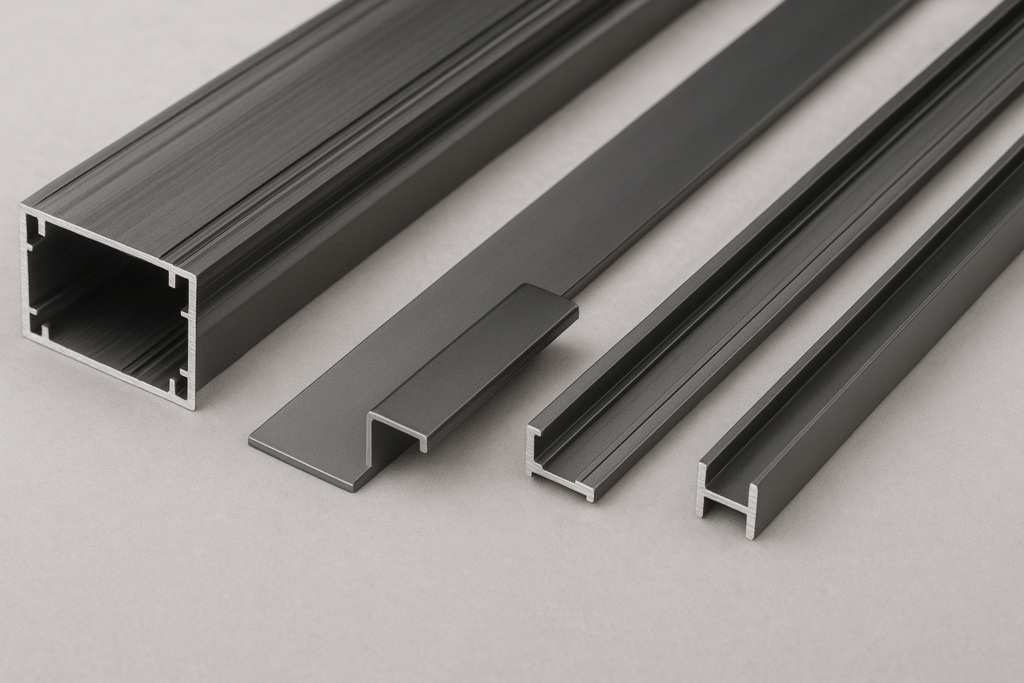

6062 aluminum is a magnesium-silicon alloy from the 6000 series, optimized for medium strength, excellent corrosion resistance, and improved surface uniformity. Unlike standard 6000 series alloys, 6062’s refined chemistry enhances machinability and formability while maintaining stable metallurgical behavior across extrusion runs.

Compared to 6061 and 6082, 6062 provides better finish quality and improved weld consistency—key factors in large-scale production or where tight tolerances and aesthetic standards matter.

Typical Composition (%):

| Element | Content Range |

|---|---|

| Aluminum | 95.8–98.6 |

| Magnesium | 0.45–0.90 |

| Silicon | 0.40–0.90 |

| Copper | 0.10–0.30 |

| Manganese | 0.15–0.40 |

| Chromium | Up to 0.25 |

| Zinc | Up to 0.10 |

| Residuals | ≤ 0.15 |

Its composition benefits sourcing teams prioritizing extruded aluminum components, anodized profiles, or high-integrity welding assemblies.

Performance and Consistency in Volume Production

6062 offers a mechanical profile suitable for structural and semi-structural parts, with performance metrics competitive with common mid-strength alloys.

Mechanical Properties (T6 Temper):

| Property | Range |

| Ultimate Strength | 290–330 MPa |

| Yield Strength | 240–290 MPa |

| Elongation | 12–16% |

| Brinell Hardness | 80–95 HB |

These attributes support CNC-ready aluminum alloy needs where reliable strength and post-processing integrity are essential.

Thermal & Physical Properties:

Density: ~2.73 g/cm³

Melting Point: ~582°C

Thermal Conductivity: ~167 W/m·K

Coefficient of Expansion: ~21.8 µm/m·°C

When your production line needs materials that maintain shape through forming and anodizing, 6062 proves efficient for use in electrical housings, modular brackets, or lightweight anodized aluminum structures, ensuring both dimensional stability and energy efficiency.

Fabrication Compatibility Across Supply Lines

6062 aluminum stands out in OEM workflows due to its compatibility across CNC machining, welding, bending, and finishing.

Machining

This alloy machines cleanly with minimal tool wear. For operations requiring cnc-ready aluminum alloy, 6062 offers stable tolerances, reducing secondary rework and polishing.

Welding

6062 is highly weldable via MIG or TIG. Post-weld recovery is effective, maintaining strength and anodizing capacity—ideal for welded enclosures or structural crossbars.

Forming

6062 supports tight radius bends and predictable shaping outcomes. Buyers benefit from lower die maintenance and reduced form-stage rejection rates.

Surface Treatment

As a lightweight anodized aluminum, 6062 is highly receptive to anodizing and powder coating, with consistent results across high-volume production. Uniformity in finish across batches is particularly valued by architectural and branded hardware clients.

Application Scenarios Relevant to Sourcing Teams

EV Frames and Modules

When sourcing for battery trays and chassis components, manufacturers rely on materials like 6062 that deliver strength without sacrificing weld quality. Stable under thermal cycling, it supports battery structure reliability and tooling cost control.

Marine and Outdoor Fixtures

Buyers specifying materials for salt-air environments choose 6062 for its corrosion resistance. Use in boat ladders, antenna mounts, and structural housings ensures lower replacement rates and longer service cycles.

Architectural and Retail Frames

For anodized window frames, partition systems, or retail fixture rails—6062 ensures reliable finish integrity across large batches, helping OEMs and architectural contractors reduce rejection rates and meet surface spec tolerances.

Heat Dissipation Units

Buyers sourcing aluminum for custom heat sinks, electrical enclosures, or lighting frameworks—including LED housings—benefit from 6062’s thermal conductivity and low deformation, making it a preferred aluminum for LED heat sinks where stable performance and long-term reliability are essential.

These applications offer sourcing advantages in terms of lead time, batch uniformity, and post-process consistency.

Comparative Value: 6062 vs Alternatives

6062 vs 6061 vs 7075 Aluminum

| Property | 6062 | 6061 | 6082 | 7075 |

| Strength | Medium | Medium | Medium-High | Very High |

| Weldability | Excellent | Good | Fair | Limited |

| Anodizing | Excellent | Good | Moderate | Poor |

| Price | Moderate | Low | Moderate | High |

| Formability | High | Moderate | Limited | Poor |

6062 offers a blend of workability and surface treatment stability. It surpasses 7075 in weld integrity and provides superior anodizing uniformity over 6061—key for buyers focused on controlling finishing costs and reducing waste.

Procurement Insights: Availability, Cost & Delivery

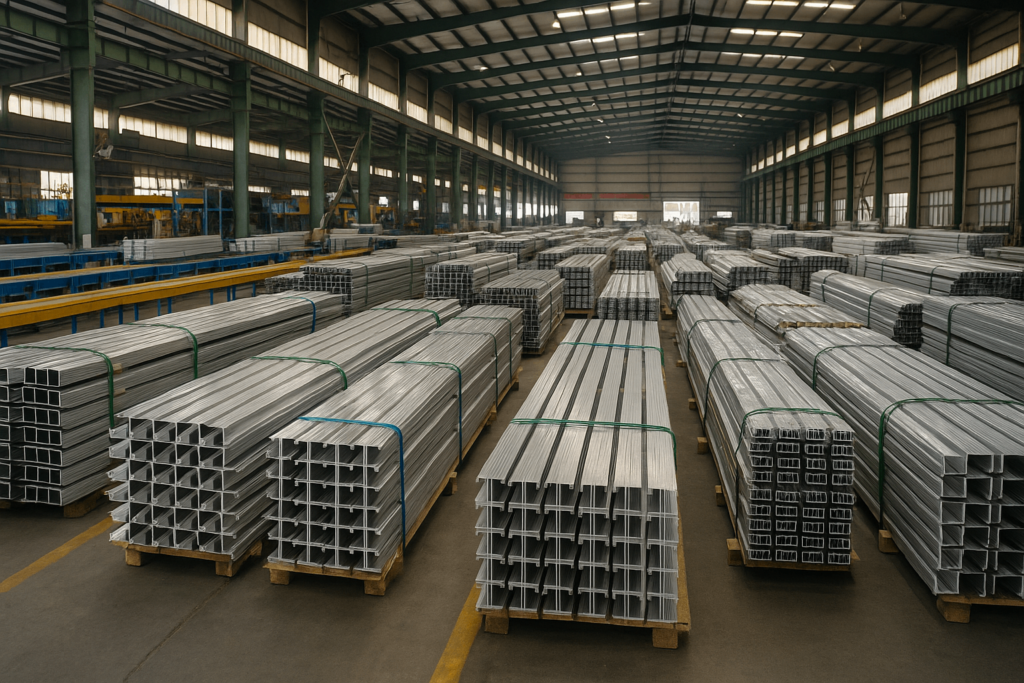

6062 is broadly available in bar, plate, and extruded aluminum components. For large orders, it offers reliable batch quality.

Lead Time: 2–4 weeks standard; variable based on customization.

Certifications: ISO 9001, RoHS compliant. YISHANG also provides MTRs, anodizing control samples, and consistent aluminum supply for OEMs needing extrusion-to-finishing integration.

Pricing Tip: As a cost-effective aluminum for forming and finishing, 6062 may carry a slightly higher base cost than 6061, but it often reduces downstream expenses thanks to faster processing, less rework, and fewer rejected parts.

Supply Coordination: Partner with suppliers offering integrated forming, machining, and finishing for faster fulfillment and traceability.

FAQs for Industrial Buyers

How does 6062 aluminum compare in long-term UV exposure for retail fixtures?

6062 performs well in UV-exposed environments when anodized, maintaining finish clarity and color stability for outdoor commercial displays or architectural panels.

Can 6062 be bent and formed?

Yes. It forms cleanly with minimal spring-back and is ideal for automated forming processes.

Is it weather resistant?

Yes—especially as lightweight anodized aluminum, it performs well in marine, industrial, and UV-exposed installations.

Can YISHANG ship globally?

Yes. As a bulk aluminum profile supplier, YISHANG delivers to 50+ countries with OEM-grade packing and lead time tracking.

Is it a viable alternative to 6061?

Yes. In applications requiring improved weldability or anodizing results, 6062 provides a processing advantage.

What certifications are usually required for bulk aluminum supply?

Many industrial buyers require ISO 9001 and RoHS compliance. YISHANG also supports traceability with MTR (Material Test Reports) and surface treatment samples for quality verification.

Final Word: 6062 for Scalable, Process-Friendly Supply

6062 helps reduce post-processing variability, enabling cost-effective manufacturing at scale.

From CNC machining compatibility to anodized surface consistency, its versatility suits industrial-scale procurement where performance and predictability converge.

YISHANG supports global buyers with engineered aluminum solutions. Send us your project specs—our team will tailor options to match your volume and processing goals.