For global B2B buyers—especially wholesale procurement managers—selecting stainless steel isn’t just about chemical composition. It involves balancing cost, batch consistency, processing efficiency, and supply chain resilience. While alloys like 316L or 440C dominate many procurement discussions, 7Cr13 stainless steel remains a reliable, cost-effective option for industrial-scale production.

At YISHANG, we’ve supported clients across 50+ countries in sourcing and customizing 7Cr13 components. These include structural parts, custom brackets, tool heads, and retail hardware. When you understand how to manufacture stainless steel like 7Cr13, you can streamline supply chains and reduce landed costs without compromising on quality or compliance.

What is 7Cr13 Stainless Steel?

7Cr13 is a martensitic stainless steel grade closely aligned with AISI 440A. With 0.60–0.70% carbon and 12–14% chromium, it delivers high hardness and moderate corrosion resistance. Under Chinese GB/T 1220-2007, it’s classified as a durable yet affordable option for dry or semi-dry industrial uses.

Buyers often evaluate 7Cr13 when comparing zinc alloy vs stainless steel or choosing between steel vs stainless steel for both aesthetic and functional applications. In procurement, this grade frequently emerges as a balanced compromise between performance and economy.

Metallurgical Profile and Processing Behavior

| Element | Content (%) | Functional Role |

|---|---|---|

| Carbon | 0.60–0.70 | Improves edge retention and wear strength |

| Chromium | 12.00–14.00 | Enables corrosion resistance |

| Manganese | 0.50–1.00 | Supports toughness |

| Silicon | 0.50–1.00 | Enhances oxidation resistance |

| Nickel | ≤ 0.60 | Assists in minor corrosion resistance |

| Phosphorus | ≤ 0.04 | Enhances machinability |

| Sulfur | ≤ 0.03 | Improves free-machining behavior |

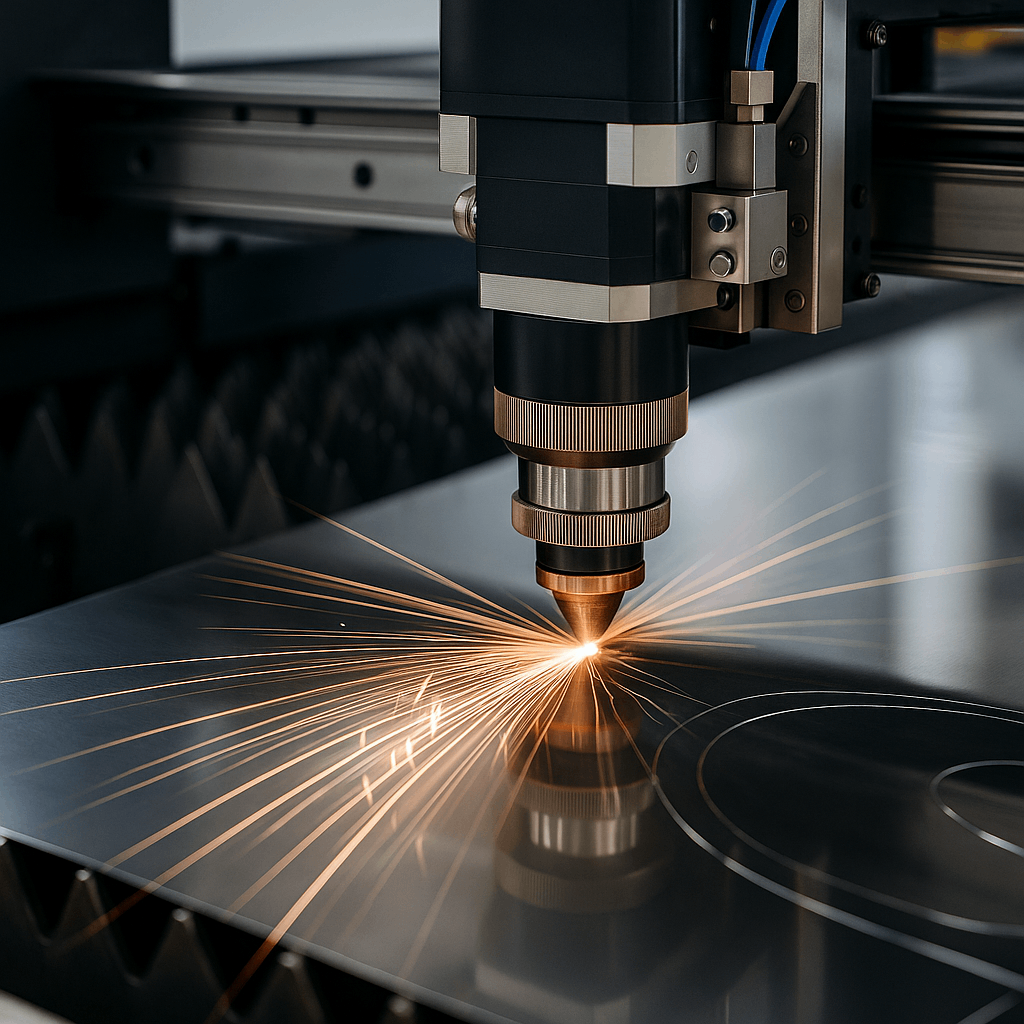

Following heat treatment (~1050°C) and tempering at 200–300°C, the alloy typically achieves HRC 54–58 hardness. Because of this, manufacturers favor 7Cr13 in CNC bending, laser cutting, and automated forming workflows.

Application Areas that Align with Procurement Priorities

Mass-Market Knives and Blades

For private-label kitchen tools and EDC blades, 7Cr13 delivers a dependable level of hardness and edge retention. It also simplifies post-processing thanks to ease of sharpening and compatibility with passivation. These features reduce rework and simplify maintenance for resellers.

Fixtures, Enclosures, and Kiosks

This grade performs reliably in brackets, vending panels, and enclosures where rust resistance and appearance matter. Its stable behavior in forming and cutting makes it ideal for high-throughput production environments. As buyers often ask how to bend stainless steel or how do you cut stainless steel sheets, 7Cr13 provides a cost-effective answer.

Brackets, Supports, and Architectural Hardware

For visible hardware in interior spaces or light structural use, 7Cr13 provides the aesthetic of higher-end grades at a lower cost. Powder coating, brushed finishing, or passivated surfaces are easily applied. These factors also reduce post-processing delays in production lines.

Efficiency in Fabrication and Procurement Considerations

Procurement teams frequently select 7Cr13 because of its consistency in fabrication and supply. Compared with low alloy steel vs stainless steel, it offers a distinct balance:

| Attribute | Advantage in 7Cr13 |

| Unit Cost | Lower than 304/316; excellent for mid-range products |

| Machinability | High—supports CNC, stamping, and bending lines |

| Weldability | Compatible with ER308L/ER309L filler rods |

| Surface Finishing Flexibility | Powder coating, passivation, PVD—all well supported |

| Supply Chain Access | Readily available in most Asian and EU sourcing hubs |

As a result, it is well suited for medium-volume OEM runs with time-sensitive delivery windows.

In high-volume blanking, tooling is not static—it evolves with every stroke. Key failure mechanisms include:

Abrasive wear, from hard materials or contaminated sheets

Adhesive wear and galling, common in stainless steel

Breakage or chipping, due to poor die alignment

Plastic deformation, when tooling exceeds its rated load

Understanding these risks matters from a cost-control perspective. If a die begins to wear unevenly, dimensional drift and burr growth occur long before visible failure. That’s why top-tier suppliers monitor punch condition in-line and perform predictive maintenance based on part count.

Comparison Snapshot: Performance vs Alternatives

| Property | 7Cr13 | 304 | 316L | Mild Steel | 440C |

| Hardness | HRC 54–58 | Lower | Lower | Soft | HRC 58–60 |

| Corrosion Resistance | Moderate | Good | Excellent | Poor | Very Good |

| Weldability | Good | Excellent | Excellent | Excellent | Fair |

| Machinability | Excellent | Good | Moderate | Excellent | Moderate |

| Unit Cost | Moderate | Higher | High | Low | High |

Because it bridges the gap between affordability and hardness, 7Cr13 remains a strategic option. Those researching difference between 304 and 316 stainless steel or 316L stainless steel vs 316 often find 7Cr13 useful in cost-controlled environments.

Trade Compliance and Technical Documentation

At YISHANG, we provide full traceability through:

Mill Test Certificates (MTC)

Batch-specific chemical analysis reports

Surface treatment and inspection documentation

RoHS compliance and material declarations

Conformance to EN 10088-2, REACH, and ANSI/ASME B36.19M standards

Although 7Cr13 is not officially designated in ASTM, it aligns closely with 440A and is globally accepted under this equivalent.

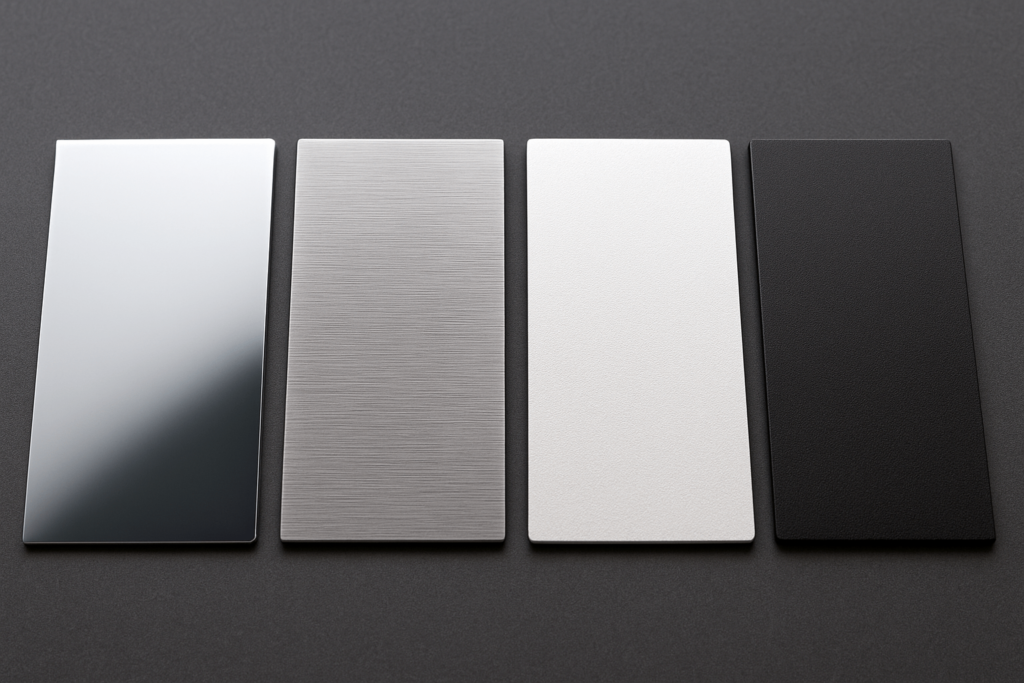

Surface Finishing Capabilities

| Finish Type | Purpose | 7Cr13 Suitability |

| Powder Coating | Decorative/protective outer coating | ✅ Excellent |

| Passivation | Enhanced corrosion resistance (hygienic) | ✅ Very Good |

| Brushed Polish | Satin effect for consumer-facing components | ✅ Good |

| PVD Coating | Color/texture control for design applications | ✅ Compatible |

These options expand the grade’s usability across industries, enhancing durability and visual appeal at scale.

Technical FAQs for OEM Buyers

Is 7Cr13 harder than mild steel? Absolutely. Its hardness outperforms mild steel, making it a strong choice for wear-prone parts.

Can it replace 304 or 316L? For dry or non-marine settings, yes. But in marine or sterile environments, 316L remains superior.

How is stainless steel manufactured for this grade? Through melting, hot rolling, annealing, pickling, and final passivation—a critical step for clean, corrosion-resistant surfaces.

Is stainless stronger than carbon steel? It depends. While carbon steel has tensile strength, 7Cr13 balances corrosion resistance and form stability for many use cases.

What welding rods work best? ER308L is suitable for stainless-to-stainless, while ER309L is preferred for joining dissimilar metals.

Final Thought: A Strategic Fit for High-Mix, Mid-Volume Orders

For procurement managers who require pricing efficiency and fabrication predictability, 7Cr13 stainless steel delivers. It balances processing flexibility and appearance while keeping material costs under control.

At YISHANG, we bring over 26 years of stainless fabrication experience to international clients. Ready to optimize your next production batch? Contact us with your drawings or RFQ—we’ll provide fast, informed support tailored to your needs.