1. Introduction: Turning Edges into Functional Value

For professional buyers and procurement specialists sourcing for high-end architectural, retail, or furniture production, edge detailing is more than aesthetics. It impacts structural integrity, assembly consistency, and brand-level finishing.

Brass edge banding offers a unique solution: blending durability, visual impact, and manufacturability in one component. At YISHANG, we’ve spent over 26 years helping OEM clients across 50+ countries integrate custom brass edge trim into production lines that demand performance, scale, and international compliance.

This article isn’t about theory—it’s written to help you understand how brass edge banding solves specific production and sourcing challenges in hospitality manufacturing, architectural metal fabrication, and beyond.

2. What Procurement Teams and Engineers Actually Face at the Edge

In mass manufacturing, exposed edges are failure points. They suffer mechanical wear, invite moisture penetration, and often lead to rework due to inconsistent finishing. Especially when joining dissimilar materials like stone to MDF or acrylic to veneer, uncontrolled expansion gaps or adhesive visibility become persistent defects.

Buyers also know that inconsistency at the edge affects customer perception. Whether you’re supplying a hotel chain, marine furniture project, or a custom retail fixture, continuity and material behavior must align across thousands of units.

Brass edge banding directly addresses these recurring pain points with dimensional stability, machining ease, and surface adaptability. It’s not a stylistic add-on—it’s a process control tool for industrial designers and procurement engineers.

3. Why Brass Is Still the Right Material in a Cost-Sensitive Market

In industrial sourcing, every material decision must justify its lifetime cost. Brass stands out not only for visual appeal but for measurable performance. It offers:

Mechanical resilience: Tensile strength between 300–600 MPa means strong impact resistance without deformation.

Thermal stability: Maintains structural integrity across temperature cycles, preventing glue line failure.

Corrosion resistance: Especially with 316-alloy compositions, ideal for marine, kitchen, or outdoor furniture use.

Compared with ABS or aluminum trim, brass doesn’t crack under torque or lose adhesion in humid conditions. Plus, its natural antibacterial surface and compatibility with high-end substrates like marble or hardwood position it well for hospitality and premium commercial environments.

From a sourcing standpoint, YISHANG provides solid brass or plated variations depending on project tier, and thickness options from 0.5 mm to 3.0 mm.

4. Manufacturing Matters: How YISHANG Delivers Consistency

Most procurement failures happen between design intent and shop-floor execution. YISHANG solves this through a tightly controlled manufacturing system.

Each brass edge trim order begins with CAD/CAM translation of your drawings. Whether curved, beveled, or flat, we ensure:

±0.05 mm thickness tolerance via CNC-guided rolling

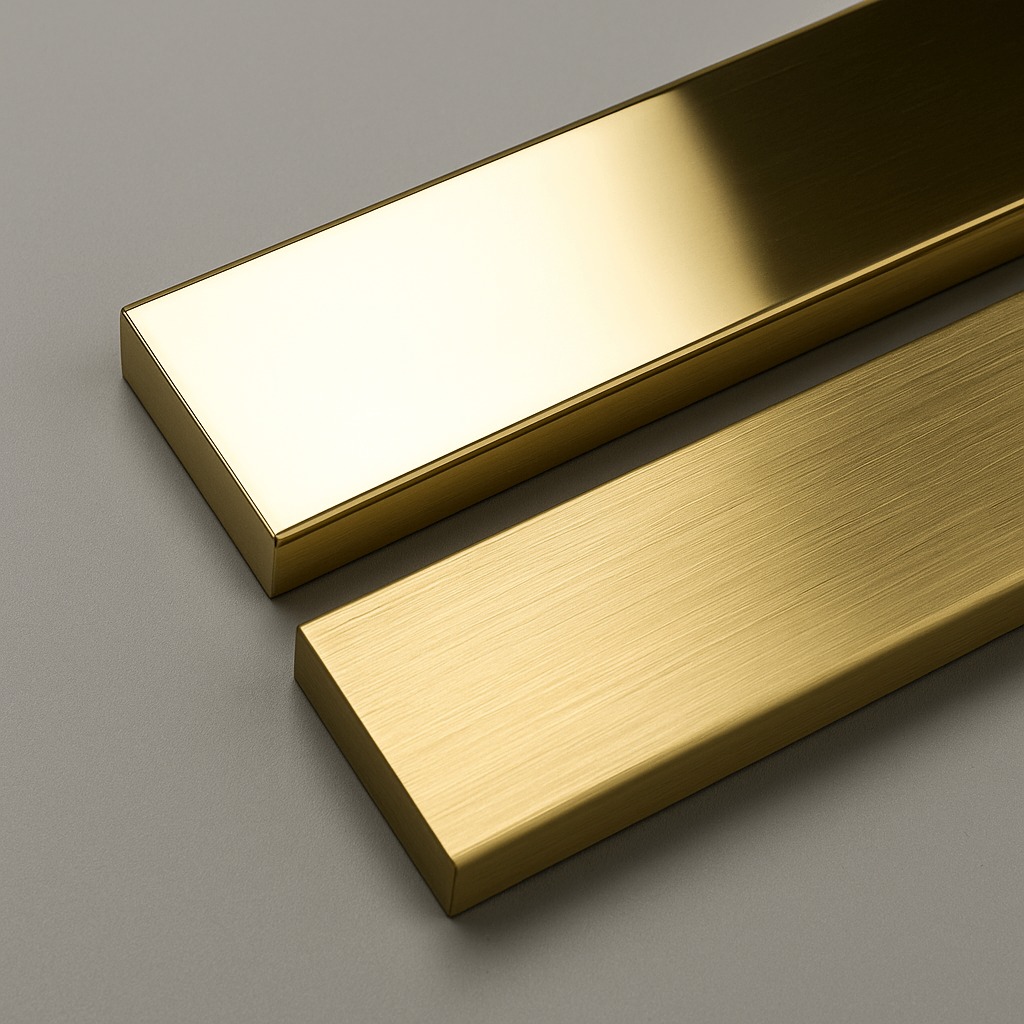

Mirror or brushed finish with lacquer sealing options

Profile repeatability across batches, using hydraulic press bending

All processes are RoHS-compliant and ISO 9001 certified. Our inline QC uses vision-guided inspection for edge uniformity, and lot traceability ensures peace of mind for high-volume exports.

We don’t just manufacture—we co-engineer with full technical transparency, including TDS (Technical Data Sheet) and material sourcing disclosures upon request.

5. Real Use Cases: Where Brass Banding Saves Cost & Adds Value

High-Wear Edges in Retail Fixtures

Standard laminates wear out under constant traffic. Our L-profile solid brass trims increase edge lifespan by 3–5x, reducing total maintenance cycles.

Mixed-Material Assembly in Furniture

Transitions from stone to MDF require precision. Brass trim masks joint lines, compensates for tolerance gaps, and prevents material separation.

Curved Hospitality Cabinetry

ABS or PVC edge bands fail under radial stress. YISHANG’s pre-curved brass trims match radii up to R20 mm, minimizing field adjustments.

Embedded Branding

We laser-etch logos into brass trims at edge level—ideal for premium cabinetry lines seeking low-profile brand presence.

Outdoor Furniture

Our 316 stainless-alloy brass banding resists moisture, salt spray, and UV, backed by accelerated corrosion testing results.

6. Installation: Simple, Scalable, Precise

For overseas buyers, ease of application is a procurement factor. YISHANG offers trim options compatible with:

Industrial adhesives with anti-bleed edge coating

Groove-insert mechanical locking

Screw-fixed removable trims (for access panels or tech enclosures)

To minimize installation variance, we offer:

Pre-drilled holes or backing templates

QR-coded installation guides

Field support via video or downloadable manuals

Packaged trims arrive with anti-scratch film and directional marking for line-side clarity.

7. From Drawing to Crate: Our Procurement-Friendly Process

YISHANG isn’t a catalog seller—we deliver engineered edge solutions. Here’s how we work with international buyers:

Drawings Submitted: 2D/3D or photos

Feasibility Feedback: Within 48 hours, incl. material & process suggestions

Prototyping: 5–7 working days

Batch QC & Traceability: Export-ready inspection protocols

| Parameter | Specification |

|---|---|

| MOQ | 500 m (profile) / 1000 pcs (unit) |

| Finish Options | Brushed / Mirror / Powder / Etched |

| Packaging | Foam corners + film + barcode tags |

| Compliance | RoHS / ISO 9001 |

We offer pallet-level consolidation for clients managing multiple components or factories, and support FCL (Full Container Load) shipping arrangements when required.

8. Care, Coating & Lifecycle Expectations

YISHANG trims undergo salt spray testing and edge durability checks. For coated trims:

Service life: 5–10 years (interior)

Recoating: Optional every 2–3 years (coastal/humid use)

Maintenance recommendations:

Wipe with microfiber and pH-neutral cleaner

Avoid abrasives and bleach

Our trims come with printed QR maintenance tags—scan to access instructions, replacement cycles, and care videos.

9. What’s Next: Performance-Driven Innovation in Edge Systems

At YISHANG, we’re not just refining edge trims—we’re redefining them. To support forward-looking design and procurement teams, we are actively developing:

LED-compatible trims for integrated ambient or task lighting

QR-coded edge identifiers to support anti-counterfeit tracking and assembly efficiency

Eco-alloy brass exceeding 40% recycled content for clients with green sourcing mandates

These technologies are already in pilot with manufacturing partners in Germany, Japan, and the UAE.

10. Export Compliance & Regional Standards

YISHANG ensures all brass edge banding complies with applicable export and client-side standards. For our key export markets:

EU: RoHS 3-compliant, REACH-compatible surface coatings

USA: Prop 65 advisory available, lead-safe finishes certified

Middle East: Moisture/humidity test certifications for marine/hotel installations

Australia: ISO 9001 manufacturing + Material Safety Data Sheet (MSDS) on request

Our export documentation includes full material declaration, HS code assignment, and country of origin certifications to meet customs and compliance requirements.

11. Conclusion

For professional buyers, brass edge banding isn’t just a line item—it’s a critical performance and aesthetics component that impacts the long-term perception and maintenance cost of your product.

YISHANG makes it easy to specify, source, and scale brass trims globally.

Send us your drawing or application spec—we’ll quote within 48 hours.