When a Gram Matters More Than You Think

In high-volume sheet metal production, especially for global supply chains, small differences in material density can lead to major consequences. For galvanized steel—a widely used and corrosion-resistant material—the density determines not only mechanical performance but also shipping class, unit pricing, and tolerance during CNC fabrication.

At YISHANG, with over 26 years of experience in OEM and ODM sheet metal manufacturing, we understand how overlooked density values cause problems for wholesale buyers. If you’re sourcing galvanized steel components for industrial enclosures, kiosks, or vending systems, knowing the true density of your specified material is critical to preventing delays, overages, or cost disputes. This article provides the data, perspective, and methods to turn density into a controllable, strategic variable.

Density and Freight Planning for Galvanized Steel in Manufacturing

Density, by definition, is the mass per unit volume (g/cm³ or kg/m³). For galvanized steel, however, it’s not a fixed number. Variability in zinc coating thickness—from processes like hot-dip galvanization or electroplating—means the density ranges from 7.85 to 8.50 g/cm³.

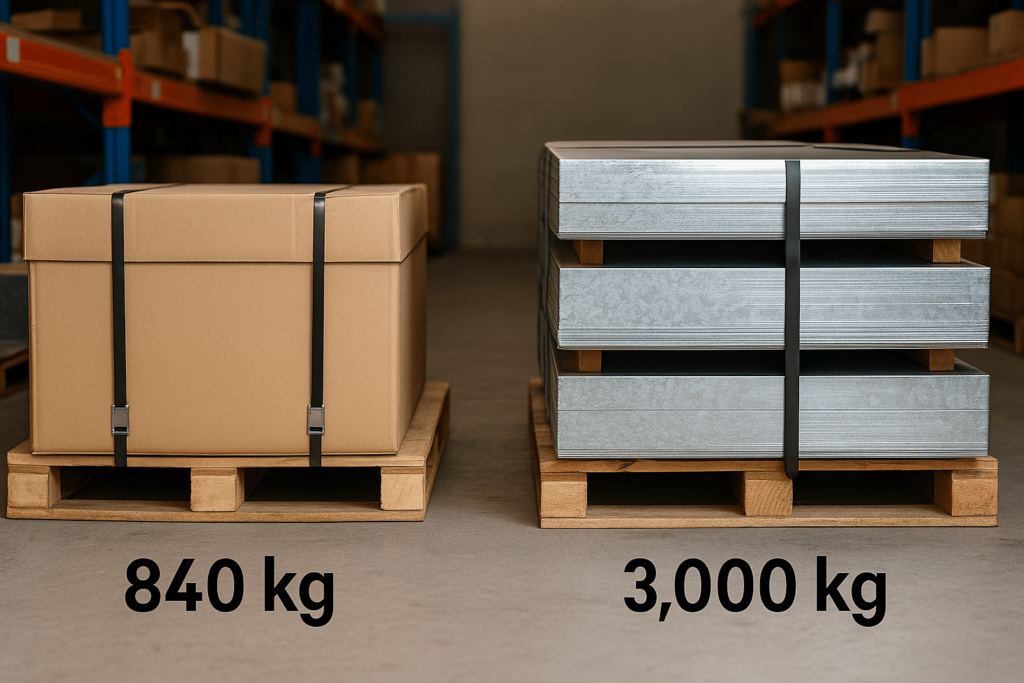

Why does this matter to you as a buyer? Because inaccurate density assumptions lead to incorrect shipping weight estimates, pricing misalignment, and in some cases, production setbacks. Consider a bulk order of 10,000 enclosures. A 0.1 g/cm³ deviation in density over each 3,000 cm³ unit results in 3 metric tons of unexpected weight.

This influences:

Container load limits

Freight quotes

Material yield from coils

Powder coating compatibility with post-galvanized parts

For our wholesale clients, YISHANG integrates actual zinc weight data into early-stage quoting, avoiding friction during downstream processes.

How Zinc Coatings Affect Density in Galvanized Steel

Galvanization protects steel from corrosion, but it also changes its density. Zinc is lighter than steel (7.14 g/cm³ vs. ~7.85 g/cm³), yet the additional layer increases the mass of each unit.

Hot-Dip Galvanization (HDG): This method can apply coatings as thick as 700 g/m². It is ideal for outdoor or structural components requiring long-term resistance.

Electro-Galvanization: Produces thinner, more consistent coatings (100–200 g/m²), commonly used in precision parts like electronics housing.

While HDG yields superior protection, it also drives part weight up—sometimes by 3–5%. This has a measurable impact on shipping cost per kilogram, a key concern for international buyers managing landed cost.

In one instance, a European automotive client spec’d galvanized brackets expecting 7.85 g/cm³. Final delivery, post-HDG, came in at 8.32 g/cm³. Result? Shipping class reclassification and additional €1,200 in air freight.

Calculating Galvanized Steel Density: From Theory to Application

Let’s break it down with a practical model. A 1m x 1m sheet, 2mm thick:

Volume: 2,000 cm³

Steel base: 2,000 x 7.85 = 15.7 kg

Zinc coating (600 g/m² double-sided): 1.2 kg

Total: 16.9 kg

Effective Density = 8.45 g/cm³

| Component | Mass (kg) | Volume (cm³) | Density (g/cm³) |

|---|---|---|---|

| Base Steel | 15.7 | 2,000 | 7.85 |

| Zinc Coating | 1.2 | 2,000 | 0.60 |

| Total | 16.9 | 2,000 | 8.45 |

YISHANG uses this level of detail for all quoting processes. For parts that undergo powder coating after galvanization, we also adjust for coating thickness when needed.

Density’s Impact on Structural Performance and Supply Chain

Architectural Fabrication

Density affects structural load calculations. Overweight wall panels can violate building codes or overburden mounting brackets. In one instance, a 2kg error per unit nearly stalled a municipal signage installation.

Electronics Enclosures

In battery housings, density influences electromagnetic shielding, thermal dissipation, and component alignment. Our customers often evaluate galvanized steel vs aluminum for this reason, balancing cost with performance.

Mass Fabrication and Forming

Incorrect density can throw off punch pressure settings or CNC bend angles. A 5% underestimation in density equals more tool wear and higher scrap rates. We preload accurate mass profiles into CAM software for predictable results.

Global Logistics

Freight cost is calculated in weight tiers. For example, a batch of kiosk enclosures misdeclared at 7.85 g/cm³ resulted in a 9.6% weight overage, bumping our client into a higher freight bracket. This is especially relevant in bulk shipments to Latin America and Southeast Asia, where margins are tight.

Galvanized Steel Density in Material Selection and Comparison

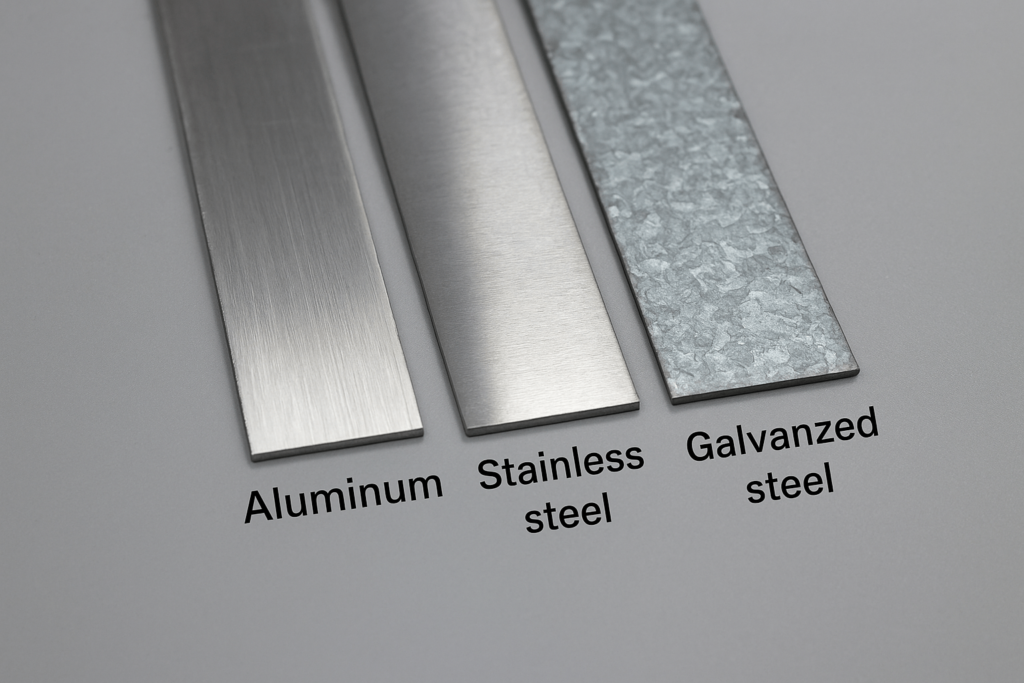

Buyers often compare galvanized steel vs stainless steel cost, or switch to aluminium and galvanised steel combinations for hybrid parts. But density must be part of that equation.

| Material | Density (g/cm³) | Avg. Cost (USD/kg) | Common Applications |

| Galvanized Steel | 7.85 – 8.50 | $0.90 – $1.20 | Racks, housings, kiosks |

| Aluminum | 2.70 | $2.50 – $3.50 | Lightweight panels, EV parts |

| Stainless Steel (304) | 7.90 | $2.80 – $3.20 | Food-safe equipment, medical |

| Copper | 8.96 | $8.00+ | Conductive components |

| Acero Galvanizado | 7.85 – 8.50 | Regional variation | Latin American infrastructure |

Depending on application, galvanized steel can outperform costlier materials by offering strength, formability, and corrosion protection—but only when its density is planned into the equation.

Avoiding Procurement Errors with Density Forecasting

We once worked with a vending OEM whose internal CAD assumed standard cold-rolled steel density. After galvanization, the project missed weight compliance by 6.3%, impacting both chassis load and wall mounting.

These issues are not design flaws—they’re data errors. Most common:

Relying on generic material specs

Ignoring zinc thickness range in HDG

Not cross-verifying density in ERP vs actual

YISHANG integrates galvanization type, target coating thickness, and post-process treatment (e.g., powder coating galvanized steel) into all density assessments. This safeguards both quote accuracy and production flow.

Making Density a Core Part of Material Sourcing Strategy

Density isn’t just a material property—it’s a sourcing variable that impacts landed cost, fabrication repeatability, and mechanical compatibility. Especially in OEM production cycles, preempting density misalignment can prevent shipment issues, scrap, and returns.

Here’s what you can do:

Include expected zinc thickness in RFQs

Ask for actual vs nominal material weights

Request a density forecast with your initial quote

YISHANG helps procurement teams worldwide reduce rework, eliminate freight overages, and protect project margins with density-aligned sourcing. Let us help you calculate right the first time.

Frequently Asked Questions (FAQ)

Is galvanized steel heavier than aluminum?

Yes, significantly. Galvanized steel has a density of 7.85–8.50 g/cm³ compared to aluminum’s 2.70 g/cm³. This matters for applications where weight influences freight cost or mobility.

What is galvanized steel used for in OEM manufacturing?

It’s widely used for electronic enclosures, frames, industrial kiosks, vending machines, HVAC parts, and battery casings—especially where corrosion resistance and structural stability are required.

How does zinc coating affect powder coating performance?

Zinc can affect surface adhesion if not properly pretreated. YISHANG applies pre-treatment steps to ensure compatibility between powder coating and galvanized surfaces.