Why Your Enclosure Design May Be Increasing Cost Without You Realizing It

Designing a sheet metal enclosure isn’t only a technical task—it’s a procurement-critical decision. At scale, the wrong material, missed tolerance, or excessive weld point becomes a cost multiplier. Enclosures that underperform in the field result in returns, delays, and warranty escalations. These issues erode profitability and slow down market response.

This article is designed to support procurement leaders, engineering teams, and product managers involved in enclosure sourcing and manufacturing. Based on over 26 years of fabrication experience, YISHANG presents practical insights that reduce production risk, lower lifecycle cost, and improve supplier collaboration—without overengineering.

Reframing the Problem: What You’re Really Buying

A metal enclosure is more than a shell. It protects electronics, integrates with components, provides access, and reflects your brand’s quality.

Procurement managers must consider not only initial cost but repeatability across large orders. Is the design manufacturable at scale? Will quality be consistent in batch 10,000 as it was in prototype 1?

Functional context changes everything: an outdoor kiosk needs IP-rated sealing; a vending machine may prioritize tamper resistance; a server rack demands thermal performance. Understanding that context helps suppliers deliver exactly what your application requires—with the right tolerances, treatments, and test protocols.

Strategic Decisions That Impact Cost and Delivery

Choosing the Right Material and Thickness

Materials influence price, process, and product longevity. While stainless steel (304/316) is ideal for corrosion resistance, aluminum is preferred for weight-sensitive builds like EV battery enclosures or telecom equipment. Galvanized steel is budget-friendly for indoor applications but unsuitable for marine environments.

| Material | Application Example | Strength | Corrosion Resistance | Finish Options |

|---|---|---|---|---|

| Stainless Steel | Medical, Outdoor Displays | High | High | Polished, Brushed |

| Aluminum 5052 | EV Housings, LED Enclosures | Medium | Medium | Powder Coat, Anodizing |

| CRS (Cold Rolled Steel) | Kiosk, Cabinets | Medium | Low | Powder Coating, Electroplated |

| Galvanized Steel | Control Boxes | Medium | Medium-High | Painted, Passivated |

Thickness directly impacts formability and structural performance. For example, thinner walls may work in small-scale aluminum extrusion enclosures but can collapse under stress during high-volume bending or press operations. Procurement teams should match thickness to structural needs and production volume realities.

Clarifying material spec and tolerance up front helps avoid back-and-forth during supplier quoting and improves BOM stability. This is especially crucial when sourcing bulk metal enclosures with tight schedules.

Designing for Fabrication Efficiency

Designs must respect press brake and laser cutting limitations. Maintain consistent bend radius: a best practice is to match internal radius with material thickness. Avoid clustering holes near edges; allow for deburring and burr-free edge quality.

We once encountered a design where louvered vents were placed too close to mounting flanges, making folding impossible without distortion. Simply moving them by 5mm enabled automated folding—saving three minutes per unit.

Buyers benefit most when the design simplifies forming, welding, and finishing. Good geometry lowers defect rates and maximizes throughput per batch. When sourcing custom sheet metal housing, design efficiency directly supports lead time and cost predictability.

From CAD to Production: How Designs Scale

Build for Manufacturability (DFM)

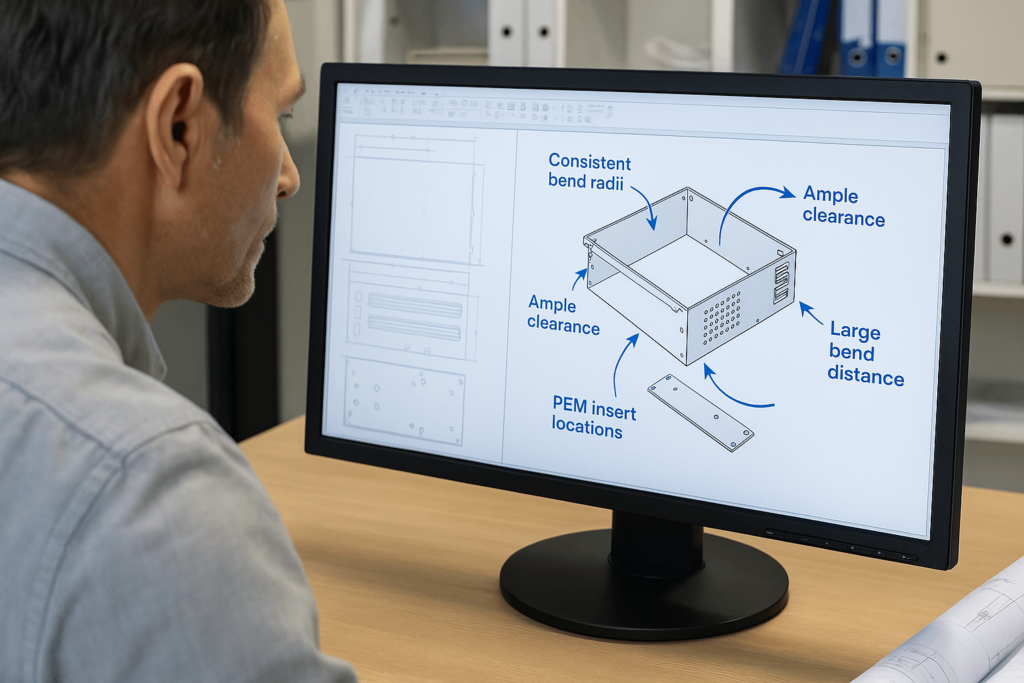

Before sending RFQs, ensure designs pass basic DFM rules:

Bend clearance > 1.5x material thickness

PEM inserts (press-fit fasteners) aligned with tool-access sides

Minimum flange length for brake grip

The earlier you identify overcomplexity, the faster you get competitive quotes. Smart buyers often ask suppliers to participate in early-stage DFM reviews, saving both parties costly revisions.

YISHANG regularly supports OEM clients with these early consultations, especially when enclosure quantities exceed 5,000 pcs or multiple variants exist.

Smart Assembly Planning

Overcomplicated joins slow down production. We’ve seen enclosures with 18 screws replaced by slot-tab assemblies and 6 press-in studs—cutting assembly time by 60%. Welds introduce heat distortion. Whenever possible, use symmetrical mating parts and accessible fastener points.

For procurement, streamlined assemblies lead to better cycle times, easier inspections, and higher yield per shift.

Testing, Validation, and Quality Safeguards

Prototype Testing Done Right

Before moving into tooling, smart procurement teams commission functional prototypes to validate key risk areas:

Load-bearing deformation

Thermal flow and ventilation

EMI and vibration shielding

Minor structural elements like cable pathways or removable access doors often introduce fit issues that only emerge in physical builds. Testing pre-production samples helps refine these before tooling.

The goal here isn’t just to confirm the design works—but that it scales. That’s where pilot batches step in.

Pilot Runs: Your Insurance Policy

Pilot batches (100–500 units) are where you confirm:

Process consistency under actual run conditions

Quality sampling plans and tolerance range adherence

Packaging durability and labeling logic

While a prototype shows functional feasibility, pilot runs simulate real-world factory execution. They bridge the final gap between prototype validation and stable production.

With many buyers reporting that over 70% of post-sample problems emerge only in mass production, pilot runs are not optional—they’re risk mitigation.

A Real Example: Redesigning for Manufacturability

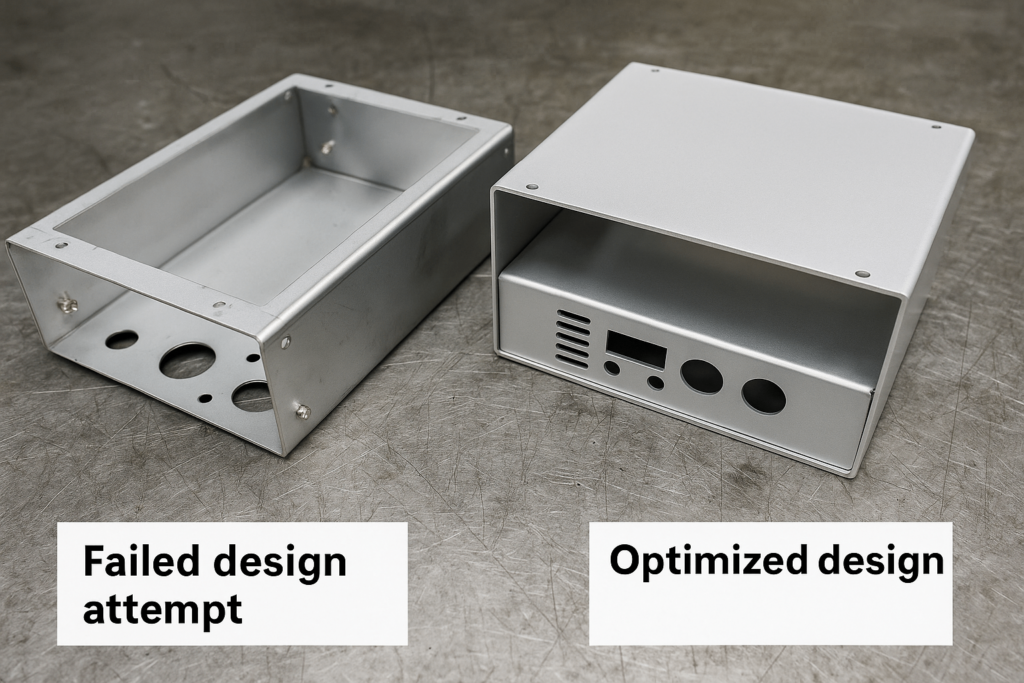

A European LED manufacturer approached YISHANG with a design that failed in production due to cracking near folded corners. It used powder-coated aluminum, 1.2 mm thick, with multiple tight bends and five welds.

We suggested a revised geometry with reduced bend angles, fewer welds, and a single-piece backplane. Welds were replaced with threaded standoffs and tabs. This saved 22% in per-unit cost and reduced rework scrap from 12% to below 1%.

Procurement teams gained better lead time visibility and fewer rejected shipments. These wins accumulate at scale.

Industries We Support

Our sheet metal enclosures are manufactured for a wide range of industries:

Medical Devices

Electric Vehicles (EVs)

Retail Kiosks and Smart Vending

Energy Storage Cabinets

Communication Equipment

We understand the certification, surface treatment, and material handling standards required in these industries.

Summary: Procurement Starts With Better Design

Great enclosure sourcing starts long before PO issuance. It begins with practical, scalable design.

Every bend, hole, finish, or joint has downstream cost and delivery impact. The buyers who win long term aren’t those who just look for the cheapest quote—but those who reduce variability, rework, and unexpected cost.

Work with suppliers who think in batches and tooling realities. And never skip the pilot run.

Looking for a sheet metal partner who speaks both engineering and sourcing? YISHANG is ISO 9001 and RoHS certified.

Contact YISHANG today to discuss your next enclosure project.