When NEMA 13 Wasn’t Enough: A Real-World Lesson

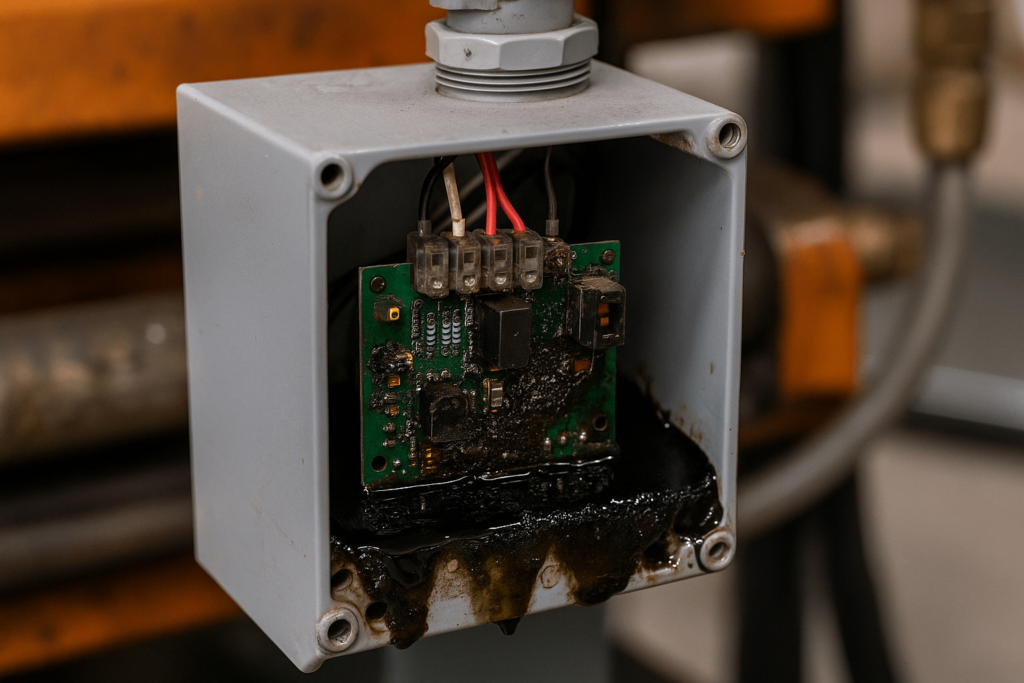

In a precision automotive components plant near Guangzhou, three NEMA 13-rated control boxes failed within 14 months. The issue? Persistent oil mist, subtle condensation, and unsealed cable entries.

This case highlights a common gap in industrial sourcing: assuming a label guarantees performance. In reality, every NEMA rating has a context. If that context isn’t understood or properly matched, reliability and ROI collapse.

This article is written for procurement engineers, product integrators, and industrial buyers who need clarity—not marketing.

What NEMA 13 Really Covers (And What It Doesn’t)

A NEMA 13-rated enclosure is designed for indoor use in environments with light dust, airborne oil, and non-corrosive coolant mist. It’s ideal for indoor locations where washdown isn’t needed, but airborne residue exists.

Under UL 50E and NEMA MG 1-2021 guidelines, a qualified NEMA 13 enclosure must block:

Dust, lint, light fibers

Dripping or sprayed non-corrosive liquids

Light oil and coolant exposure

It’s frequently selected for machinery rooms, equipment panels, indoor automation lines, and packaging control boxes. It’s comparable to NEMA 12, with the key difference being oil resistance.

But it is not waterproof, not corrosion-proof, and not for outdoor conditions. For example, if you’re comparing NEMA 12 vs NEMA 4, or NEMA 13 vs NEMA 3R, NEMA 13 falls short in weather and washdown resistance.

Where NEMA 13 Performs Well (Real Use, Not Theoretical)

YISHANG supplies thousands of NEMA 13 enclosures per year across North America, Western Europe, and Southeast Asia. These products serve machine tool integrators, electrical wholesalers, and OEM product builders.

Typical NEMA 13 Procurement Scenarios

Indoor CNC rooms (U.S., Vietnam): airborne oil mist is constant, but no water spray or corrosive fumes.

Automated packaging (Canada, Australia): powdered materials and oil require tight seals but not full waterproofing.

Indoor ESS cabinets (Europe): control units need to resist dust and thermal cycling, not rain.

Case in Focus: Warehouse Automation in France

A logistics integrator needed control boxes for autonomous drone recharging stations. The warehouse had minor oil mist from conveyor belts but no humidity issues. NEMA 13 was chosen over NEMA 12 to protect PLCs and HMIs. Result: zero failures in 18 months across 76 units.

Procurement decision-makers appreciated that NEMA 13 delivered the required protection—without overpaying for a NEMA 4X or IP66 enclosure.

What NEMA 13 Doesn’t Do (And Why That’s Okay)

Misuse of NEMA 13 usually stems from one mistake: confusing oil resistance with waterproofing.

NEMA 13 Doesn’t Mean:

Suitable for outdoor use

Withstands pressurized hose-downs

Resists chemicals, detergents, or salt fog

Impact- or vibration-rated

Explosion-proof or ATEX-certified

A key confusion comes when comparing NEMA 3 vs 3R vs NEMA 4. While NEMA 3R is meant for outdoor rain protection, NEMA 13 provides none. It’s a fundamentally different rating.

If your environment includes moisture, acidic vapor, or outdoor temperature cycling, NEMA 4X is often a better long-term choice despite higher upfront cost.

Build Quality Matters: Not All NEMA 13 Enclosures Are Equal

At YISHANG, we’ve evaluated dozens of third-party NEMA 13 enclosures. Results vary widely.

Some fail under simple water spray. Others degrade quickly in oily environments. The spec sheet says NEMA 13—but the materials, seals, and fabrication don’t deliver.

YISHANG’s Key Enclosure Practices

Seam-welded joints (not tack-welds)

Gasket compression testing (EPDM, silicone)

Powder coating up to 80 µm

Precision latch systems for consistent pressure sealing

We’ve seen cases where the gland sealing was the weak link—not the panel body. That’s why we test assembled units, not just components.

Should You Upgrade? NEMA 13 vs 12, 3R, 4, and 4X

| Rating Comparison | Oil-Resistant | Water Jet-Resistant | Corrosion-Resistant | Outdoor Use | Impact-Rated |

|---|---|---|---|---|---|

| NEMA 13 | ✓ | ✗ | ✗ | ✗ | ✗ |

| NEMA 12 | ✓ (limited) | ✗ | ✗ | ✗ | ✗ |

| NEMA 3 / 3R | ✗ | ✗ | ✗ | ✓ (3R) | ✗ |

| NEMA 4 | ✓ | ✓ | ✗ | ✓ | ✓ |

| NEMA 4X | ✓ | ✓ | ✓ | ✓ | ✓ |

If you’re sourcing enclosures in bulk, remember: selecting NEMA 13 over NEMA 4X could save upfront cost, but result in faster failure in high-moisture environments.

If you’re comparing NEMA 12 vs NEMA 3R, remember that NEMA 3R can go outdoors, but won’t handle oil or dust as well.

A Practical Framework for Enclosure Procurement

To simplify sourcing decisions, ask these five questions:

What is the real operating environment? Indoor vs outdoor, humidity, exposure cycles.

What ingress risks exist? Oil mist? Water jets? Cleaning agents?

How sensitive is the equipment? Will heat buildup or static affect performance?

Are there future access needs? Will users need to modify wiring, access ports, or add sensors later?

What certifications apply? UL, CE, IEC? Is a NEMA-to-IP conversion needed (e.g., NEMA vs IP55)?

YISHANG offers guided assessments and custom design support for buyers managing regional compliance and large-volume technical sourcing.

Will NEMA 13 Stay Relevant in 5 Years?

Yes, but not without refinement.

Buyers are asking for smarter enclosures—ones that allow thermal monitoring, real-time access, and better integration with sensors and IIoT modules.

YISHANG is already prototyping:

NEMA 13 enclosures with thermal interface materials

IoT-ready cable entry ports

Modular mounting plates for field reconfiguration

For wholesalers and OEMs, the advantage lies in balance: competitive cost, targeted protection, scalable design.

Why Work With YISHANG?

With over 26 years of production experience, YISHANG is a trusted metal enclosure supplier to buyers in over 50 countries. We serve procurement professionals in:

Automation and machinery

Energy storage and utilities

Medical equipment

Security and communication systems

What sets us apart:

OEM/ODM-ready capabilities

Fast prototyping and sampling

CNC, TIG, powder-coating in-house

RoHS and ISO 9001 compliant QC

We don’t just sell metal boxes. We help you protect your systems reliably—at scale.

Conclusion

NEMA 13 enclosures are not a one-size-fits-all solution, but in the right use case, they deliver exceptional performance-to-cost value.

If you’re sourcing for indoor environments with oil mist, dust, or mild humidity—without corrosive washdowns—NEMA 13 may be the perfect fit.

Let our team help you specify the right enclosure, avoid misapplications, and ensure long-term system protection.

Contact YISHANG today to request drawings or a sample for your next project.