A Practical Breakdown for Procurement Professionals

For global wholesale buyers and OEM procurement managers, confusion between transformers and inverters often results in incorrect sourcing. This leads to certification failures, delays in production, or added cost in retrofit adjustments.

According to MarketsandMarkets, the inverter market is expected to reach USD 35 billion by 2028, largely due to demand in solar systems, EV infrastructure, and industrial automation. Meanwhile, power transformers remain vital in distribution networks and mission-critical machinery.

At YISHANG, we support global clients across 50+ countries with housing and system-ready solutions for both transformers and inverters. This article goes beyond basic comparisons—it focuses on real procurement implications, field-tested integration knowledge, and the cost-risk factors buyers care most about.

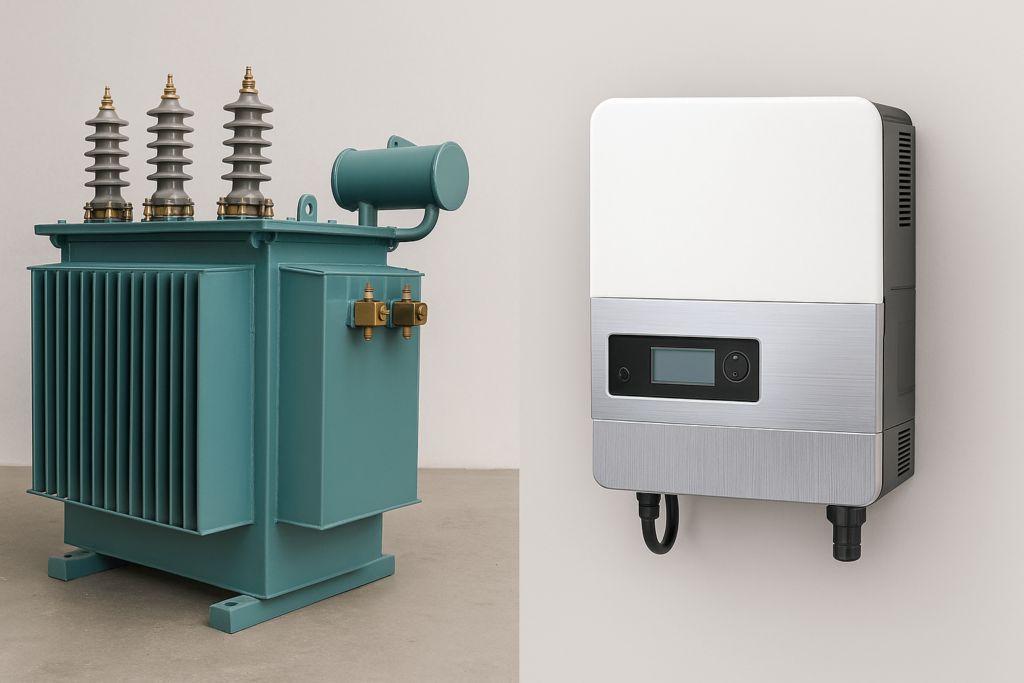

Understanding Function: What Inverters and Transformers Actually Do

A transformer adjusts AC voltage levels through magnetic coupling—stepping voltage up or down without changing current type. It’s used when electrical isolation or high-voltage conversion is required.

An inverter, by contrast, takes DC input and converts it to AC output, using PWM-based semiconductor switching. Common in solar and battery-powered systems, inverters are programmable and often used for waveform synthesis and frequency control.

When buyers ask “what is a transformer used for,” the answer depends on voltage, frequency, and whether the system needs isolation. In many procurement scenarios, both devices are required.

Application Realities: Where Your Customers Use Each Device

Transformers: Where Stability and Safety Matter

Transformers remain essential in:

Industrial machinery that runs on stable 50/60Hz supply

Building automation systems requiring galvanic separation

Telecom and medical gear where interference shielding is critical

Procurement teams often specify these based on IEC 60076 standards. We support them with RoHS-compliant, dustproof housings for railways, coastal installations, and warehouse automation hubs.

Inverters: Where Smart Control and Conversion Are Key

Inverters are crucial in DC-driven applications like:

Solar PV systems, especially off-grid

EV charging modules, requiring dynamic AC outputs

Data centers with uninterrupted power supplies (UPS)

LSI keywords like “solar inverter applications” or “inverter vs converter” often emerge in buyer queries. At YISHANG, we integrate passive and forced cooling layouts to ensure inverters meet CE and UL thermal regulations in tight enclosures.

The Hidden Risks of Misuse: Procurement Misconceptions

One common sourcing error: assuming an inverter can handle voltage isolation. A client from Southeast Asia once eliminated the transformer in a vending system, believing the inverter was sufficient. Certification tests failed due to EMI leakage.

We added a compact isolation transformer with shielded routing—resolving the issue. This underscores a truth: unless your inverter has isolation built-in (which many don’t), adding a transformer is not optional.

Buyers should confirm:

Load type: is it inductive or resistive?

Expected voltage range and frequency stability

Regional compliance standards (EN 55032, CISPR 22, etc.)

This isn’t about electrical theory. It’s about system reliability, warranty risk, and factory audit pass rates.

Comparative Table: Technical Implications That Impact Sourcing

| Feature | Transformer | Inverter |

|---|---|---|

| Current Conversion | AC to AC | DC to AC |

| Voltage Control | Fixed via winding ratio | Software-configurable |

| Isolation | Yes (by default) | Not inherent |

| Efficiency Range | 95–98% | 85–94% depending on switching frequency |

| Harmonics | Very low | Moderate to high without filtering |

| Maintenance | Low (passive device) | Moderate (cooling, firmware updates) |

| Service Life | 20–30 years | 8–12 years average |

| Cost Predictability | High | Medium to variable |

Smart buyers use this comparison early in RFP planning, especially when lifecycle cost (TCO) is a concern.

Trends in Power Electronics: Where the Market Is Heading

As reported by the International Energy Agency (IEA), inverter adoption in distributed solar systems will surpass 300GW globally by 2027. This shift underlines the growing importance of smart, scalable conversion systems that adapt to renewable energy variability.

Inverters today offer more than conversion. With SiC (silicon carbide) switching, they operate at higher efficiency. Many include embedded diagnostics, RS485/Modbus integration, and multi-phase output—all relevant for modern procurement specs.

Solid-State Transformers (SST) now blend magnetic and semiconductor stages. While still emerging, they show promise in microgrid or marine power systems. Procurement teams should watch this space if sourcing for projects involving energy storage or intelligent substation components.

That said, transformers will remain dominant in high-stability, heavy-load, and galvanically isolated environments.

What Bulk Buyers Should Really Care About

For high-volume projects, we often get these questions:

1. What about durability? Transformers have longer lifespans, especially in humid or unstable voltage environments. Inverters can degrade if thermal paths are poorly designed or ventilation is blocked.

2. What’s the maintenance load? Inverters may need capacitor replacement after 5–7 years. Transformers generally require dust cleaning and basic insulation testing every few years.

3. Are there import/export compliance concerns? Yes. For example, many countries require EN/UL labels on inverter modules, while transformers often need type-tested insulation certificates.

YISHANG helps buyers pre-integrate housing elements and design for compliance, reducing factory inspection risks.

Real-World OEM Cases: Sourcing Smarter, Not Harder

Case A: Solar Inverter for Telecom Site

Issue: Overheating due to undersized vent path

Fix: YISHANG redesigned a heat sink-integrated enclosure with active airflow channels. Result: 100% runtime uptime in 45°C ambient.

Case B: Transformer in Industrial Conveyor System

Issue: Noise interference on control loop

Fix: Shielded metal core transformer + IP65-rated housing. Result: EMC certification passed on first inspection.

These examples show how smart hardware design and sourcing alignment reduce time-to-market and system failure risks.

Optimize Around Your End Use

Sourcing a transformer or inverter isn’t just a parts decision. It’s a system-level investment. Global buyers evaluating BOMs for solar systems, EV stations, or factory control modules should look beyond wattage or price.

Think in terms of:

Environmental exposure (humidity, vibration, dust)

Electrical load profile

Lifecycle expectations

Certification and warranty requirements

YISHANG supports buyers by supplying more than just metal—we co-develop housing and integration-ready solutions with procurement teams.

Quick FAQs

Do I need both a transformer and inverter?

Often yes, especially in hybrid solar/grid or medical systems.

How long does an inverter last vs. transformer?

Inverters: 8–12 years. Transformers: 20+ years.

What’s more energy efficient?

Transformers in stable AC grids. Inverters for flexible DC conversion.

Which one is easier to maintain?

Transformer. It’s passive, no moving parts.

Can YISHANG provide both enclosure types?

Yes. We fabricate housings optimized for either, or both in hybrid units.

Ready to optimize your next power system build with the right structure and protection?

Contact YISHANG today for tailored housing and integration solutions.