Introduction: Material Selection with Business Consequences

For global wholesale buyers and procurement professionals, selecting between stainless steel and sterling silver is more than a technical preference. It’s a procurement decision that affects product lifecycle, cost-efficiency, supply chain predictability, and post-sale performance. At YISHANG, we’ve supported clients across 50+ countries in making better sourcing decisions by looking beyond surface value.

In this article, we compare these two metals from the lens of B2B purchasing, focusing on technical data, sourcing challenges, and total cost of ownership.

According to the International Stainless Steel Forum, global demand for 304 and 316 stainless steel has continued to grow steadily—up by over 6% in 2024—reflecting its reliability in diversified industrial and commercial supply chains.

Understanding the Materials: Why Composition Matters to Buyers

Stainless Steel: The Procurement-Friendly Industrial Standard

Stainless steel, especially in 304 and 316 grades, is a durable alloy known for reliability in mass production. 304 grade stainless steel is commonly used due to its excellent machinability, corrosion resistance, and low cost. For harsher environments like marine or chemical exposure, 316 stainless steel offers higher chloride resistance and increased mechanical strength. These alloy and stainless steel combinations form the backbone of industrial production, offering consistency and performance across sectors. Many certified alloy ss parts rely on these material profiles.

Sterling Silver: Elegant but Less Scalable

Sterling silver (92.5% silver and 7.5% copper) excels in applications requiring high electrical conductivity or luxury aesthetics. But for bulk sourcing, its lower mechanical strength (~170 MPa), tarnish sensitivity, and price volatility limit its practicality. Unlike stainless steel grades, silver’s softness can compromise structural integrity in load-bearing or industrial applications.

Key Performance Metrics That Affect Wholesale Outcomes

Mechanical Strength and Production Resilience

304 stainless steel ultimate tensile strength typically ranges from 505 to 620 MPa, while 316 stainless extends further with added molybdenum. These properties enable reliable CNC machining, welding, or bending operations. Sterling silver lacks this robustness, increasing the likelihood of deformation or production rejects.

In projects involving custom laser cutting or forming enclosures and frames, stainless steel maintains its shape and finish quality more consistently. Both 304 and 316 stainless deliver yield strength suitable for structural retention.

Corrosion Resistance and Environmental Tolerance

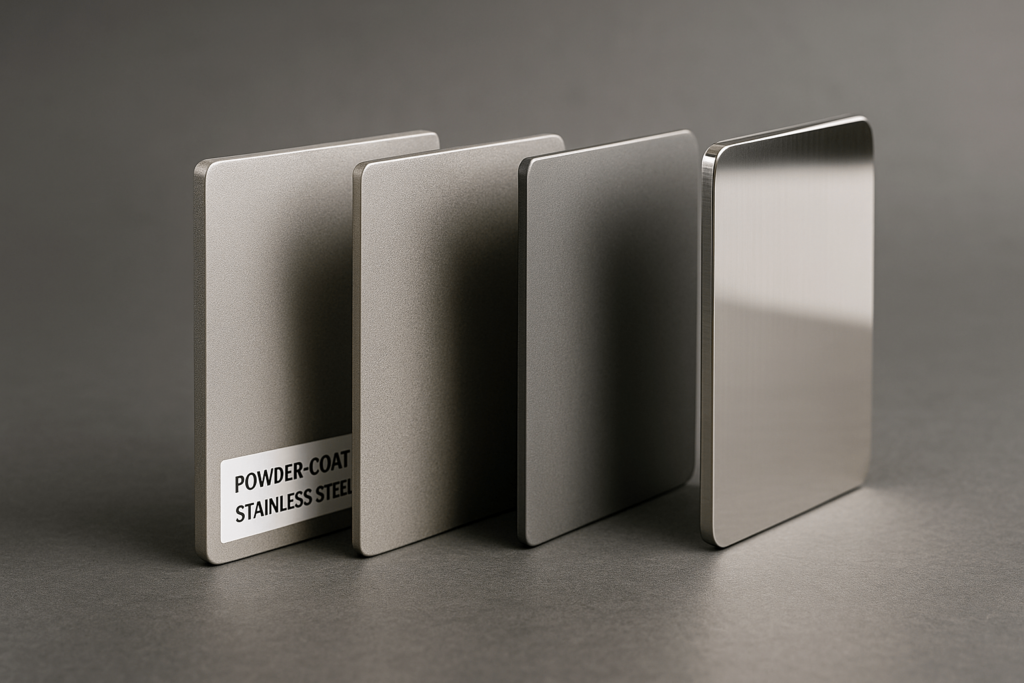

316 stainless steel properties provide excellent resistance to chlorides, acids, and cleaning agents, making it ideal for food-grade, sanitary, or outdoor components. Sterling silver, prone to tarnishing from air or skin contact, often requires additional protection such as anti-oxidation packaging or replacement by powder-coated stainless steel in some applications.

In coastal or chemically active environments, stainless steel remains the lower-maintenance and longer-lasting choice.

Thermal and Electrical Conductivity: Use-Driven Decision

Silver’s conductivity (63 x 10^6 S/m) is unmatched, making it ideal for high-precision electronics. However, most industrial applications prioritize strength and heat resistance. 304 stainless steel withstands temperatures up to 870°C, offering sufficient thermal tolerance for heating and structural use.

Total Cost Considerations: The Bigger Picture

Buyers evaluate the full cost structure of materials, not just price per kilogram. Factors like fabrication speed, maintenance cycles, and storage stability play significant roles.

| Metric | 304/316 Stainless Steel | Sterling Silver |

|---|---|---|

| Raw Material Price (2025 est.) | $2.50–$3.50/kg | $700–$900/kg |

| Fabrication Efficiency | High (standardized tooling) | Low (requires hand polishing) |

| Packaging Needs | Basic | Requires anti-tarnish support |

| Storage Risk | Minimal | High (tarnish over time) |

| Lifecycle Maintenance | Low | High |

Stainless steel, particularly 304 and 316 grades, supports efficient mass production and lower operational costs. Its stable pricing, minimal rework, and supply chain predictability make it the smarter choice for most industrial procurement.

Surface and Finishing: What Impacts Buyer Satisfaction

Finish Durability and Post-Processing Needs

304 stainless steel hardness ensures strong resistance to scratching and deformation during transit or installation. Finishing techniques like powder coating or bead blasting enhance durability further. Silver, while bright initially, tarnishes quickly, often leading to cosmetic defects or return requests.

Many OEM buyers request bending stainless steel tubes for display racks, carts, and stands. The material retains shape well and avoids cracking, which supports efficient batch production.

In terms of abrasion resistance and lifecycle, stainless outperforms alternatives like chrome or silver in most industrial applications.

Processing Compatibility for Large Batches

304 stainless steel machinability allows for high-speed punching, folding, and CNC operations. Though 316 stainless machinability is slightly lower, it still suits large-scale workflows. In contrast, silver’s softness and need for manual polishing reduce efficiency and consistency.

FAQs

Q: What’s better for export-grade kitchenware: 304 vs 316 stainless?

A: 316 offers enhanced resistance to acids and salts, but 304 is typically sufficient for standard applications.

Q: What does 18/10 stainless steel mean, and is it different from 304?

A: 18/10 refers to chromium and nickel content. It often overlaps with 304 stainless steel chemical composition in cookware-grade materials.

Q: Is sterling silver more expensive long term?

A: Yes. Besides raw price, silver’s higher maintenance and susceptibility to tarnish increase total ownership cost.

Q: Can I powder coat stainless steel?

A: Definitely. Powder coating improves surface resilience and is common in outdoor and architectural components.

Q: What is the difference between stainless 304 vs 316 in bending and forming?

A: 304 is easier to form and machine. 316 offers better corrosion resistance and is slightly tougher.

Q: Is stainless better than surgical steel for medical devices?

A: In most cases, 316l ss offers similar or better corrosion resistance and strength compared to surgical steel.

Q: What is the best alloy stainless for corrosive environments?

A: 316l ss is typically preferred due to its superior resistance to chlorides and harsh chemicals.

Need help choosing the right material grade for your application? Contact YISHANG for technical guidance tailored to your sourcing needs.