Why Duct Material Is a Procurement Decision—Not Just a Spec

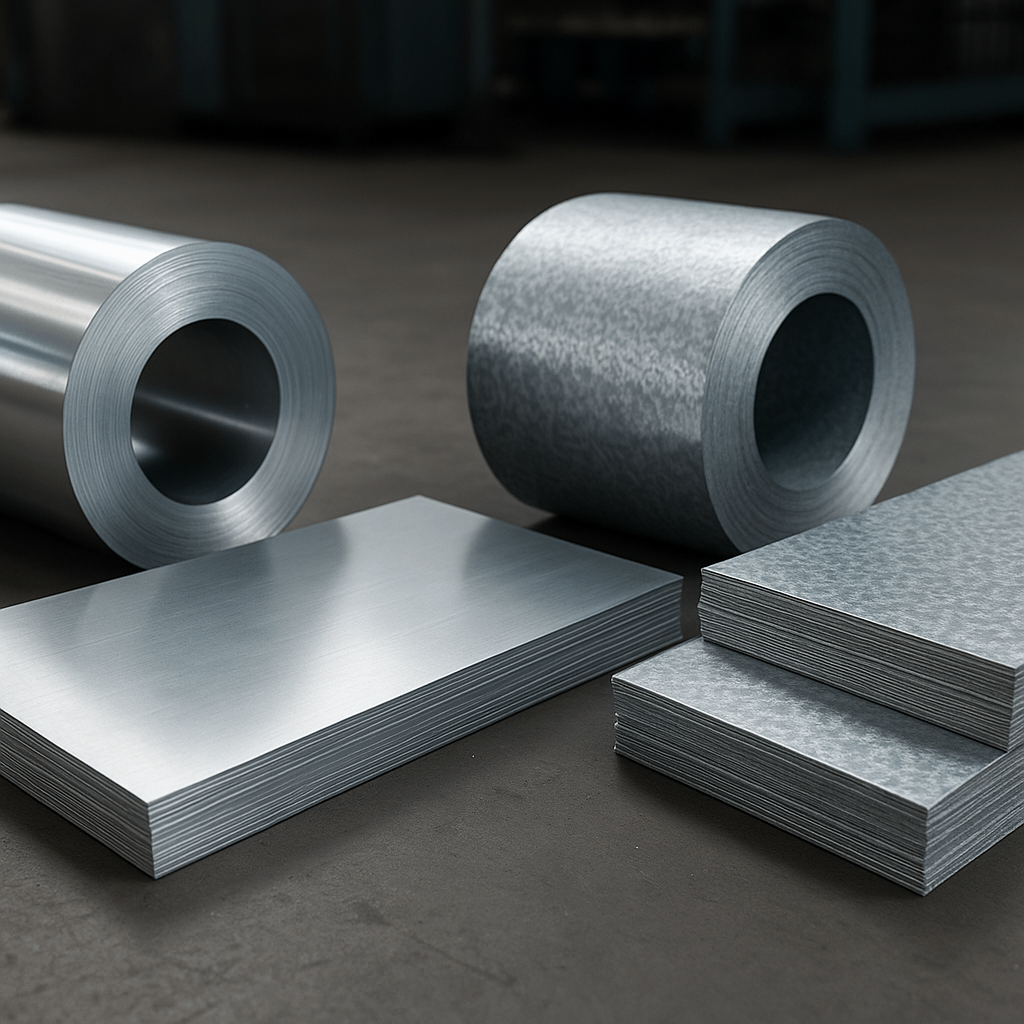

For international procurement professionals and HVAC wholesalers, the question “What is ductwork made of?” goes beyond material names. It directly impacts system efficiency, project compliance, and supply chain risk.

Material choice affects lifecycle cost, corrosion resistance, ease of fabrication, and energy consumption. Hidden from sight, duct materials still dictate visible system inefficiencies if chosen poorly.

At YISHANG, we’ve supported global buyers across 50+ markets, helping them select the right duct materials—not just to meet technical specs but to perform across climates, project types, and usage cycles.

We understand these queries signal action: choosing materials that reduce risk, cut long-term costs, and ensure regional compliance.

Understanding the difference between ductboard and metal duct helps prevent system misapplication in cost-sensitive environments, particularly in commercial retrofits.

Manufacturing and Fabrication: Why Process Matters for Material Performance

Material alone doesn’t define duct performance—how it’s fabricated and sealed makes the difference between a compliant system and a costly retrofit.

At YISHANG, we use CNC laser cutting to maintain dimensional accuracy, especially when producing large volumes for global shipment. For aluminum and stainless steel ducts, we apply TIG welding and orbital seam processes to reduce porosity.

For OEM clients, we offer notching, perforation, and powder coating options to reduce site labor. This customization is especially helpful for customers sourcing UL 181 certified duct assemblies or pre-assembled bulk duct modules.

Based on our experience with bulk duct supply for industrial projects, especially in Southeast Asia, we’ve learned that precision in flange bending and gasket fitting can reduce on-site sealing time by over 30%, particularly under fast construction schedules or regulatory inspections.

Real-World Procurement Errors

Too often, poor project outcomes are blamed on design—but the real issue lies in material mismatch or overlooked compliance.

In one Middle Eastern project, a distributor used fiberglass ducts for a data center to save cost, only to face total replacement due to static discharge failures. Another retail chain in Latin America experienced air leakage exceeding 20% after installing flexible duct where rigid galvanized was required.

How to Audit for Material Fit

Buyers must look beyond initial pricing and confirm:

Is the material appropriate for humidity, airflow, and cleaning?

Are certification documents included (e.g., RoHS compliant HVAC materials)?

Can your supplier meet food grade air ducts or cleanroom-level sealing?

Does the system meet low leakage duct design targets for energy-sensitive zones?

Stainless steel remains the best ductwork material for hospitals and food-processing facilities due to its non-reactive surface and sanitary resilience.

Today, experienced teams weigh lifecycle ROI and long-term resupply risks—well before contract finalization.

To learn more about relevant performance benchmarks, refer to ASHRAE’s duct design criteria and UL 181 certification details.

What Procurement Teams Are Demanding Now

Today’s procurement decisions prioritize outcomes like faster installs, reduced TCO, and easier compliance.

Key procurement drivers include:

Modular duct systems pre-assembled to minimize installation time

Ducts that streamline installation in tight or restricted zones

Duct material for commercial buildings with certified coatings (e.g., antimicrobial, food-grade)

Compatibility with smart building planning and maintenance access needs

For example, insulated ducting for commercial buildings is now favored in mid-rise office retrofits due to acoustic and thermal dual-performance benefits. This trend reflects practical sourcing shifts—not abstract green targets.

Matching Duct Types to Project Environments

If you’re comparing HVAC duct types by project, consider installation constraints, local compliance thresholds, and maintenance frequency alongside initial material spec.

In public projects, pre-insulated or corrosion-resistant ducts reduce long-term risk and enhance safety.

For procurement professionals comparing metal duct types for HVAC systems, these changes signal the move toward high-performance, install-ready materials across both new builds and retrofits.

When evaluating options, many buyers now search for commercial HVAC ductwork solutions or energy efficient ductwork systems to align performance with sustainability goals.

Final Thoughts: Support Starts with Informed Decisions

Choosing the right duct material isn’t just an engineering decision—it’s a business one. Misaligned choices lead to rework, compliance delays, and operating inefficiencies.

At YISHANG, we provide material recommendations not from a catalog—but from 26+ years of export-oriented manufacturing practice. Whether you’re seeking ducts for coastal environments, UL-certified bulk orders, or hybrid systems for energy-efficient retrofits, we can support your evaluation process.

Looking for project-ready advice? Reach out to the YISHANG team to get tailored suggestions that align with your specs and supply goals.