Why Choosing the Right Structural Tubing Isn’t Just About the Spec

ASTM A500 tubing ((ASTM A500/A500M-21, ASTM International)) plays a pivotal role in steel-based construction and OEM fabrication. But for many wholesale buyers, it’s often viewed as a generic spec instead of a performance-critical decision.

Misjudging grade, geometry, or tolerance can disrupt schedules and escalate downstream costs. Tubing isn’t just metal—it must fit within tight engineering parameters.

Choosing the right A500 tubing means thinking beyond datasheets and toward fabrication realities, cost control, and long-term structural integrity.

A500 Tubing: Structure, Format & What It’s Really Used For

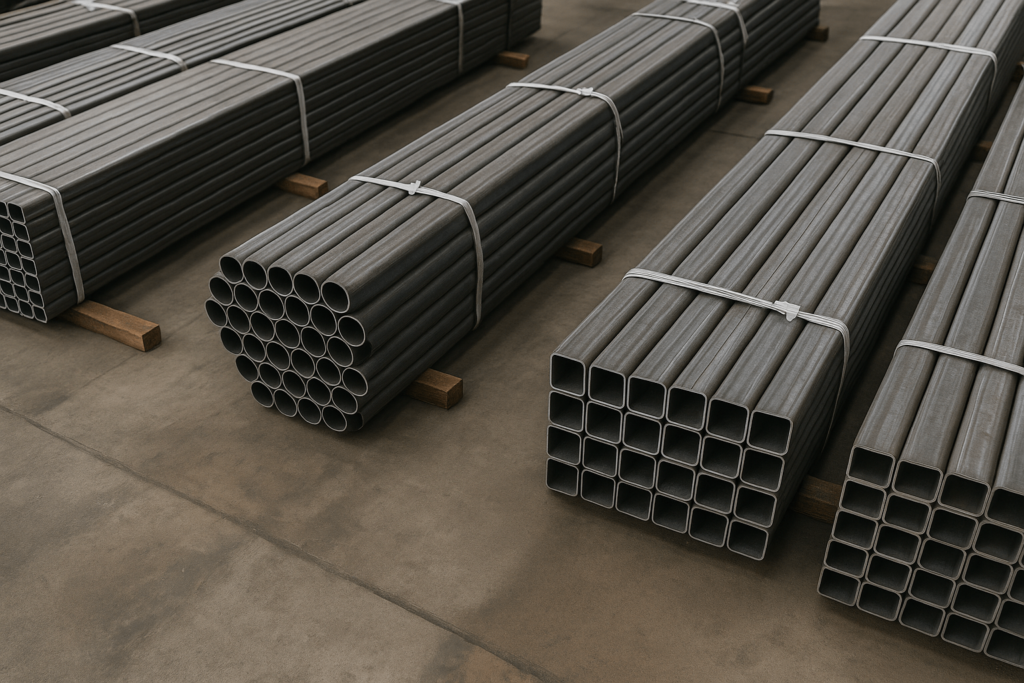

ASTM A500 covers cold-formed carbon steel tubing in round, square, and rectangular formats. It’s engineered for load-bearing, structural, and architectural uses.

Its cold-formed nature means better strength and dimensional stability compared to hot-rolled options like ASTM A36. For modular construction, CNC workstations, or high-precision fixtures, A500 delivers higher consistency per meter.

In high-volume structural systems—like solar racking structures, modular building supports, or commercial signage framing—this reduces the need for secondary machining. It also improves weld alignment and minimizes failure points in assembly, which wholesale buyers consider when comparing total landed cost.

Grades A, B, C, and D: Which One Works for Your Project?

A500 includes four grades, each tailored to specific mechanical and use-case demands:

| Grade | Yield Strength (ksi) | Typical Use |

|---|---|---|

| A | 33 | Lightweight, decorative frames |

| B | 46 | Universal structural components |

| C | 50 | Telecom towers, solar support frames |

| D | 36 (round only) | High-load round columns |

Grade B fits most general-purpose builds. It offers enough strength while being flexible in fabrication. Grade C is preferred where rigidity matters more—like longer spans or exterior bracing—but may require welding adjustments due to its higher carbon content.

Understanding your project’s fabrication process helps determine whether strength or formability should take priority.

If you’re sourcing across North America, ASTM A500 Grade B is compatible with CSA G40.21 Grade 350W, simplifying binational specs.

Fabrication Compatibility: What Buyers Must Consider

Assuming all tubing grades behave the same under fabrication is risky.

Differences in wall thickness, internal stress, or weld seam quality will affect processes like CNC coping, robotic welding, or edge chamfering.

A500 performs well under precise conditions where hot-rolled steel often warps. For instance, bending steel tubing from Grade A or B can mirror alloy steel tube bending but with fewer defects. However, Grade C might resist bending due to strain hardening—so plan accordingly.

Transitioning from stainless or alloy components to A500 often reveals different forming tolerances. Buyers should validate tubing compatibility through real-process trials—such as test bends or chamfers—to ensure fitment precision and prevent costly rejection cycles.

Fabrication success isn’t about theoretical fit—it’s about how seamlessly the tubing integrates into your production workflow, without slowing or retooling your line.

Surface Treatment & Coating Considerations

Unlike stainless, A500 must be coated to resist corrosion. Zinc galvanizing, powder coating, or industrial painting are all valid options—especially for galvanized A500 tubing used in exposed applications.

That said, coating introduces new requirements: welded sections must be vented for hot-dip zinc flow. Masking must align with design tolerances. If you’ve worked with polished surfaces like cintrage tube inox or bent stainless tubing, note that A500 doesn’t offer aesthetic shine—but with proper finish, it’s serviceable for unseen structural use.

Buyers working with marine, agricultural, or exposed urban installations must specify the coating process in their RFQs—including hole placement for venting during galvanization and surface prep for post-painting steps. Common trade terms such as FOB and CIF should be clearly specified, along with expected lead times.

Assembly & Logistics: What Global Buyers Often Overlook

A500 tubing is available in stock lengths and custom cuts. Ordering custom-cut steel tubing for structural framing reduces waste, aligns precisely with assembly lines, and optimizes logistics costs (FOB China), especially in prefabricated modular buildings and signage frame systems., particularly when integrated into precision jigs or fixtures.

Buyers should also check for OD/ID consistency. This is vital when inserting cross-members or using plug-in joints—especially if switching from seamless products like stainless tube or A519.

ASTM A500 vs Other Tubing Types: A Practical View

Compared to A513: A513 is mechanical—not structural. Its tolerances and strength are unsuitable for any building-frame load. Still, it’s often mistaken due to visual similarity.

Compared to A36: A36 has a lower yield strength and lacks uniformity in wall thickness. While cheaper, it requires more onsite correction work. A500 reduces rework and welding time.

Compared to Stainless: If your team normally uses 3in stainless steel pipe for bracing but now faces budget limits, A500 with galvanizing can reduce cost up to 60% while retaining strength. That’s why bending stainless steel tubing is increasingly replaced with engineered A500 frames in telecom and advertising units.

Compared to EN Standards: In Europe, EN 10219 is a common equivalent. A500 Grade B often aligns with S355JRH but requires documentation review for cross-acceptance.

Qualifying Your Supplier: Beyond the Basics

Just meeting ASTM A500 isn’t enough. Buyers should qualify the mill or fabricator.

Request mill test reports (MTRs), dimensional checklists, and coating certifications. Look for suppliers offering weld seam integrity testing (ultrasonic or radiographic), not just visual inspection.

A qualified supplier should also support cut-to-length or mitered ends, surface prep for powder coating, and export-grade packaging with dimensional records—especially important for large-volume orders.

Cut-to-length or mitered ends

Surface prep for powder coating

Packaging to match port-of-entry handling

Tolerance charts with every shipment

A partnership approach avoids misalignment between spec and deliverable—saving your team hours on QC and rectification.

FAQs: What Procurement Teams Often Ask

Q4: What is the typical lead time for exporting ASTM A500 tubing from China? Typical lead times range from 4–6 weeks FOB China, depending on order quantity and customization requirements.

Certifications and technical documents are available upon request.

Q1: Is ASTM A500 suitable for automated welding lines or robotic assembly? Yes. Its dimensional consistency and cold-formed uniformity reduce misalignment risks during robotic welding. However, verify wall thickness against your weld settings.

Q2: What is the typical MOQ when sourcing ASTM A500 from China-based suppliers? Many export-focused manufacturers like YISHANG support flexible MOQs, but standard containerized shipments often begin around 5–10 metric tons.

Q3: Can A500 tubing be bent similarly to stainless steel tubing or alloy tubing? Grade A or B tubing can undergo moderate cold bending, similar to bending stainless steel tubing, though it’s best to consult with your forming team for tight-radius work.

Think Application, Not Just Specification

ASTM A500 tubing goes beyond raw material status—it’s a cross-functional engineering asset that shapes how your structures perform, how your workflows scale, and how your costs stay contained.

Procurement teams that evaluate not just what’s on the spec sheet but how tubing behaves in real installations win long-term. Let’s connect if you need tubing that performs as specified—start to finish.