When 0.4 mm Becomes a Million-Dollar Decision

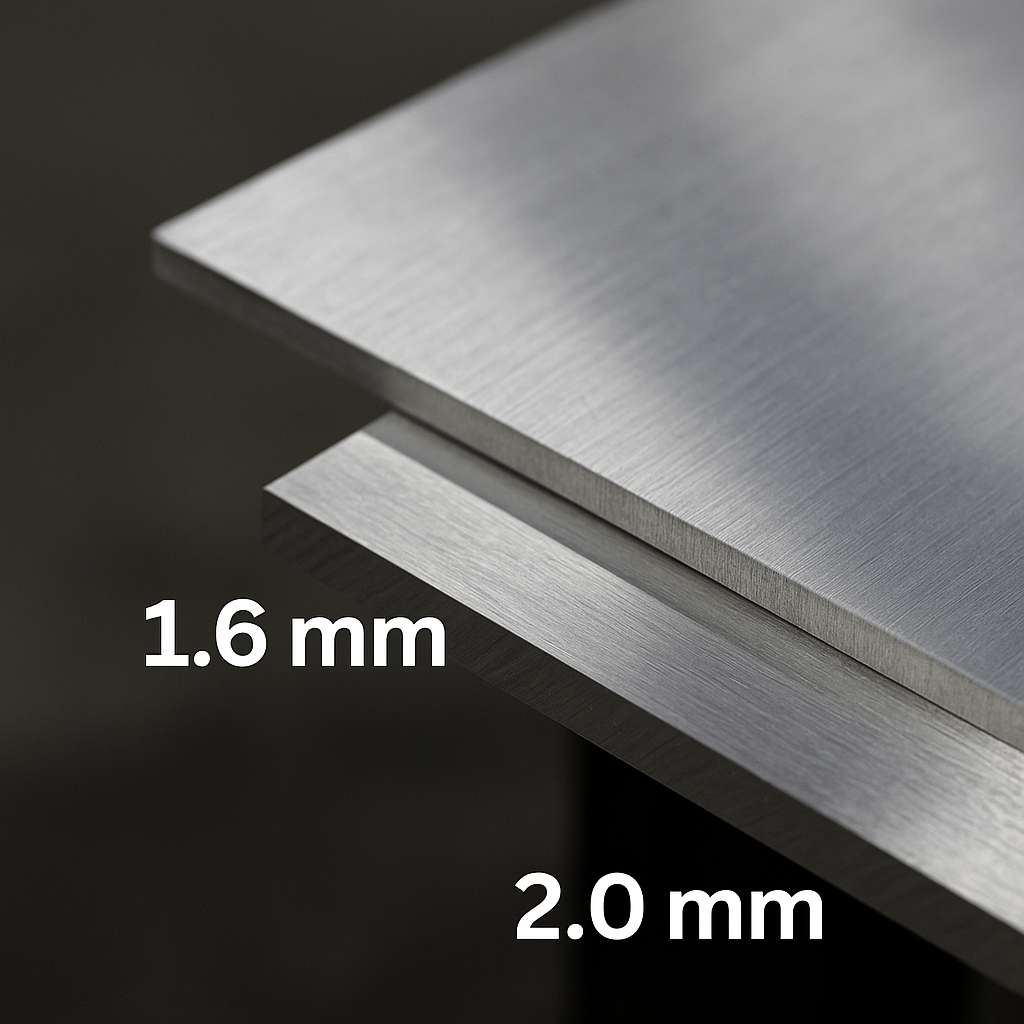

You’re reviewing a purchase order for 30,000 custom metal kiosks. Your engineer specifies 2.0 mm aluminum sheet. Your supplier quotes 1.6 mm, citing cost and shorter lead time. At first glance, it seems minor—just 0.4 mm.

But that decimal can shift your landed cost, shipping weight, fabrication time, import code—and even post-installation durability.

That 0.4 mm could mean a 5% shift in landed cost or a critical impact on component fit during final assembly. We’ve seen how procurement decisions around aluminum sheet thickness shape cost control, quality assurance, and delivery consistency.

Let us run a tolerance vs. cost comparison for your BOM—it could reveal hidden margins.

Sheet Thickness: A Lever for Bulk Procurement Optimization

Choosing a specific thickness impacts far more than structural rigidity. It determines:

Sheet metal cutting speed

Tool selection, such as the aluminum plate cutter

Tariff classification under HS codes

Weight per square meter and freight efficiency

In bulk procurement (e.g., 20 tons), a 0.2 mm adjustment can result in:

3–4% raw material savings

20% faster cutting cycles

Improved throughput in aluminum sheet bending

These aren’t theoretical gains—they’re measurable margins that matter to your bottom line.

Gauge vs. Millimeter: Why Precision Wins

While gauge sizes are still common in conversation, they often create confusion. Gauge isn’t standardized across materials, and using it without cross-checking can result in serious quoting or fabrication errors.

For example, 14 gauge aluminum ≈ 1.98 mm, but 14 gauge steel is thicker. That’s why millimeter-based RFQs are now the norm.

Common Gauge to mm Equivalents (from Aluminium Sheet Gauge Chart)

12 gauge = 2.67 mm (used in structural frames)

14 gauge = 1.98 mm (common in vending shells)

16 gauge = 1.60 mm (display units, kiosks)

18 gauge = 1.27 mm (electrical housing covers)

Also confirm thickness tolerance. Among reliable aluminum sheet metal fabricators, ±0.04 mm is standard.

Reframe Cost: Thickness as a Margin Lever

A European customer revised their aluminum sheet metal material from 2.0 mm to 1.6 mm. The result?

$5,700 saved in raw material

12% lighter shipments, reducing container cost

Lower import duties under reclassified HS code

The thinner material also meant faster cutting and forming—reducing machine time and operator hours.

These efficiencies accumulated beyond just “material savings.” They created operational cost advantages across fabrication, assembly, and shipping.

Compare this spec with your current BOM—how far apart are they?

Engineering Meets Finance: Data Over Guesswork

While the previous section focused on material and logistics savings, this section highlights how thickness choices directly tie into design integrity and cost justification.

Our team helps buyers use finite element analysis (FEA) to simulate structural needs across different gauges.

For example:

6061-T6 often needs ~1.5× thickness to match bend safety vs 3003-H14

3003-H14 can handle tight bends at original gauge

This kind of simulation helps buyers justify specs not only to engineers, but also to finance teams requiring data-backed decisions.

It’s worth noting that anodized aluminum sheeting adds 10–15 μm per side—relevant when precision tolerances apply.

Let us run a tolerance vs. performance simulation to align your targets with real-world results.

Fabrication Time: How Thickness Affects Throughput

Sheet thickness directly affects cycle time:

1.2 mm aluminum sheet metal cuts at ~17 m/min

2.0 mm cuts at ~9 m/min

This translates into:

Shorter CNC cycles

Reduced tool wear

Faster aluminum sheet bending and deburring

Balancing fabrication speed with required structural performance is a key consideration in both prototyping and production.

How to Cut Aluminium Sheet Metal in Bulk Efficiently

For large-volume buyers, cutting efficiency is crucial. Using nitrogen-assisted fiber laser cutters reduces edge burrs and speeds up production. For sheets above 2.5 mm, water jet cutting may provide a cleaner finish with less thermal distortion. Matching the cutting method to sheet thickness helps optimize cost and output.

Logistics Meets Spec: What RFQs Often Miss

Spec sheets might include thickness, but RFQs often lack context. Key oversights include:

MOQ thresholds: e.g., 0.7 mm sheets may require 10-ton minimums

Market availability: uncommon gauges like 1.3 mm may face long lead times

Machine compatibility: not all aluminum sheet metal fabricators handle >6 mm stock

We recommend confirming what’s in stock, expected MOQ, and substitution options (e.g., 1.5 mm instead of 1.6 mm). For varied-volume orders, custom cut aluminum sheets may offer flexible fulfillment.

Beyond logistics, thickness also plays a role in long-term durability and lifecycle cost.

Enclosures and Cabinets: Choosing the Right Thickness

Enclosures used in automation, energy storage, and electronics need specific balance: lightweight design with strong structural integrity. Common aluminum thicknesses for enclosures range between 1.2 mm and 2.0 mm, depending on the application.

For weatherproof electrical cabinets or control boxes, 1.5 mm anodized aluminum sheeting is often preferred for its corrosion resistance and rigidity.

Buyers must consider not just strength but also thermal dissipation, grounding paths, and formability—making the fabrication gauge decision a critical early step.

This is where aluminum enclosure fabrication moves beyond product design into operational reliability.

Durability Meets ESG: Why Thicker Can Be Smarter

Beyond enclosure applications, thickness also impacts product return rate and circular economy outcomes.

One vending machine OEM upgraded from 0.8 mm to 1.2 mm skins. Results included:

40% drop in returns due to denting

Improved product lifespan

Cleaner alloy yield at recycling

For brands with ESG benchmarks, lightweight aluminum sheet for export isn’t just about grams saved. It’s about total lifecycle performance.

Buyer Outcomes: Data from Real Projects

Battery Tray (EU EV Startup)

Changed from 2.0 mm to 2.4 mm

Improved rigidity by 48%

Avoided $1.4M in after-sales service costs

Retail Display (US-based distributor)

Shifted from 14 gauge to 16 gauge (with flanges)

Reduced 12% weight per unit

Saved $55K across 50 tons

Silo Base Plate (Brazilian agricultural company)

From 2.0 mm to 3.2 mm

Achieved 2× longer reinforcement cycle

In each case, the shift in thickness was not isolated—it informed broader design and procurement strategies in their next project cycle. That’s where marginal specs turn into scalable value.

Recommended Spec Template for RFQs

Many B2B buyers waste days waiting on clarifications. This spec format solves that.

Want fast and accurate responses from suppliers? Use a clear spec like this:

Material: 5052-H32 aluminum sheet

Thickness: 1.60 mm ±0.04 mm

Finish: Anodized (15 μm per side)

Panel Size: 1000 x 2000 mm

Fabrication: Aluminum sheet bending, punching, deburring (Ra ≤ 0.6 μm)

Volume: 20 metric tons (monthly delivery: 5 tons)

Certifications: ISO 9001:2015, RoHS, SGS optional

Delivery: FOB Shenzhen

Lead Time: Within 8 business days from PO confirmation

We’re happy to review your RFQ or spec sheet and provide feedback within 24 hours—no obligation.

Final Takeaway: A Spec with Strategic Reach

Aluminum sheet thickness is more than a technical detail—it’s a procurement lever that drives:

Quoting clarity

Import classification

Tool path and cycle time

Material usage and waste rate

Managing it wisely means tighter cost control and fewer sourcing surprises. We’ve helped hundreds of buyers align spec with outcomes.

Ready to review yours? Let us run a tolerance vs. cost comparison for your BOM.