Choosing the right material is one of the most crucial decisions in any custom metal fabrication project. It impacts not only product performance and durability, but also long-term ownership costs and supply chain resilience.

For OEM buyers, engineers, and industrial procurement teams, this guide offers a practical framework for selecting metals that balance cost, manufacturability, and corrosion resistance—backed by real-world performance data.

Consider this example: a petrochemical manifold pipe made with a low-grade alloy failed at 22,000 hours. The redesigned version, made from a more suitable material, lasted over 83,000 hours. That’s the payoff of smart sourcing.

This article moves beyond textbook specs to help you make strategic, ROI-driven material decisions tailored for high-stakes B2B environments.

The Most Common Showdown: Carbon Steel vs. Galvanized vs. Stainless Steel for Outdoor Applications

For wholesale buyers, selecting the right steel for outdoor products directly impacts marketability and long-term brand perception. This choice is a classic balancing act between initial capital outlay, product durability, and the maintenance burden passed on to the end-user.

This quick-decision chart summarizes the core trade-offs from a procurement perspective.

| Feature | Coated Carbon Steel | Galvanized Steel | Stainless Steel |

|---|---|---|---|

| Initial Cost | ★☆☆☆☆ (Lowest) | ★★★☆☆ (Moderate) | ★★★★★ (Highest) |

| Corrosion Resistance | ★★☆☆☆ (Relies on Coating) | ★★★★☆ (Very Good) | ★★★★★ (Excellent) |

| Maintenance Needs | ★★★★★ (High) | ★★☆☆☆ (Low) | ★☆☆☆☆ (Minimal) |

| Long-Term Value (ROI) | ★★☆☆☆ (Low) | ★★★★☆ (Good) | ★★★★★ (Excellent) |

The optimal choice depends on the product’s intended service life and market positioning.

Scenario 1: Budget-Priority, Temporary Projects

For applications like temporary construction fencing or event structures, coated carbon steel is often a pragmatic choice due to its low upfront cost, which is compelling for high-volume orders with tight budgets.

However, its complete dependence on a protective coating makes it a high-maintenance option. This is a viable short-term solution, but not one that builds a reputation for longevity.

Scenario 2: The “Value Engineering” Choice for Permanent Structures

When you need a durable, low-maintenance solution without the premium price of stainless steel, galvanized steel offers the perfect middle ground. The zinc coating provides a dual-action defense against corrosion.

First, it acts as a physical barrier. More importantly, it provides sacrificial protection. Zinc is more electrochemically active, meaning it corrodes first to protect the steel underneath, even if scratched. This makes it the workhorse for applications where a balance of cost and performance is key.

Scenario 3: High-Stakes and High-Visibility Applications

For projects in harsh environments (coastal, marine, or industrial), stainless steel is the undisputed champion. Its corrosion resistance is an inherent property derived from the chromium in its alloy.

While the initial investment is highest, its superior performance and minimal maintenance often result in the lowest total cost of ownership. This makes it the go-to material where failure is not an option and long-term value is the primary metric.

The Hidden “Cost-Killer”: How to Prevent Galvanic Corrosion from the Start

Imagine sourcing thousands of beautifully fabricated aluminum enclosures, only to receive field reports of severe corrosion around the steel fasteners. This is the costly reality of galvanic corrosion, a hidden liability that can lead to widespread product failure and warranty nightmares.

Also known as dissimilar metal corrosion, this reaction occurs when two different metals are in electrical contact in the presence of an electrolyte (like moisture), turning your assembly into a tiny, self-destructing battery.

The problem often manifests in seemingly benign combinations. Using a standard zinc-plated steel screw on a stainless steel panel creates a galvanic cell where the zinc coating on the screw rapidly sacrifices itself, leaving the underlying steel to rust.

An even more dangerous combination is using steel fasteners on an aluminum part. The aluminum becomes the anode and corrodes aggressively around the fastener, potentially leading to catastrophic failure.

The following risk matrix provides a quick reference for common material pairings.

| Base Metal ↓ / Fastener Metal → | Zinc & Galvanized Steel | Aluminum & Alloys | Carbon Steel | 304/316 Stainless Steel |

|---|---|---|---|---|

| Aluminum & Alloys | Low Risk | Low Risk | Moderate Risk | High Risk |

| Carbon & Galvanized Steel | Low Risk | Low Risk | Low Risk | High Risk |

| 304/316 Stainless Steel | High Risk | High Risk | High Risk | Low Risk |

Green = Low Risk, Yellow = Moderate Risk, Red = High Risk of accelerated corrosion.

Preventing galvanic corrosion is straightforward if addressed during the design phase:

- Choose Compatible Metals: Select metals close to each other in the galvanic series. Use stainless steel fasteners with stainless steel parts, and aluminum fasteners with aluminum parts.

- Isolate the Metals: If dissimilar metals are necessary, break the electrical circuit. Use non-conductive washers, gaskets, or sleeves made from materials like nylon or neoprene.

- Control the Environment: Galvanic corrosion cannot occur without an electrolyte. Keeping the assembly dry is a powerful preventative measure. Ensure designs allow for water drainage and avoid crevices where moisture can become trapped.

Advanced Selection: Head-to-Head Matchups for Specific Scenarios

For a procurement manager, selecting the right grade of a material is about optimizing cost and performance—avoiding both under-engineering (which leads to failure) and over-engineering (which inflates costs).

304 vs. 316 Stainless Steel: When is Paying More for 316 a Smart Investment?

Grade 304 is the versatile workhorse of the stainless steel world. Grade 316, however, contains a secret weapon: molybdenum.

This addition gives 316 drastically enhanced resistance to corrosion from chlorides, found in saltwater, de-icing salts, and many industrial chemicals.

While 316 is more expensive, that extra cost is a necessary investment in any chloride-rich environment.

Use this simple checklist for your procurement decision:

- Will the product be used in a marine or coastal environment?

- Will it be exposed to de-icing salts or industrial chemicals?

If “yes,” specifying Grade 316 ensures long-term durability and avoids premature failure. For all other applications, the more economical Grade 304 is typically sufficient.

6061 vs. 5052 Aluminum: The Critical Trade-off Between Machining and Forming

Mistaking these two aluminum alloys is a common and costly error that leads to high scrap rates and production delays—a major concern for any buyer managing a supply chain.

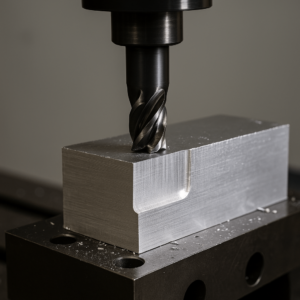

- 6061 Aluminum (The Machining King): This heat-treatable alloy is hard, strong, and boasts excellent machinability, making it ideal for parts that are milled, drilled, or turned from a solid block. However, this hardness makes it brittle during forming; attempting to bend 6061-T6 to a tight radius will almost certainly result in cracking.

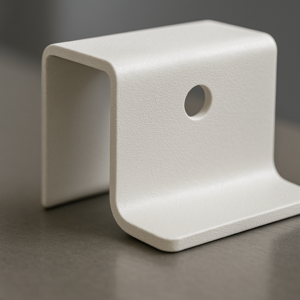

- 5052 Aluminum (The Sheet Metal Expert): This non-heat-treatable alloy possesses excellent formability and can be bent to tight radii without fracturing. It also offers superior weldability and better corrosion resistance, especially in marine environments.

The rule of thumb for sourcing is simple: If the part’s geometry is created by removing material (machining), specify 6061. If created by bending and shaping sheet material (fabrication), specify 5052.

The Finishing Touch: Don’t Let Surface Treatments Ruin Your Precision Design

Surface treatments like anodizing and powder coating are powerful tools, but they introduce a critical variable often overlooked in design: thickness. Failing to account for this can turn a perfectly designed assembly into a collection of parts that no longer fit—a nightmare for final assembly and quality control.

A clearance of 0.1mm between two parts can easily become an interference fit after both surfaces receive a 75-micron layer of powder coating. Threaded holes can become clogged, and precision mating surfaces can fail to align.

Coating thickness must be treated as a critical design tolerance from the very beginning.

| Coating Type | Typical Thickness | Impact on Tolerances |

|---|---|---|

| Anodizing (Type II) | 8-13 µm (0.0003″-0.0005″) | Minimal; rarely affects fit unless tolerances are extremely tight. |

| Powder Coating | 50-100+ µm (0.002″-0.004″+) | Significant; will affect all but the loosest fits. |

| Hot-Dip Galvanizing | 45-85+ µm (0.0017″-0.0033″+) | Significant; especially critical for threaded components. |

Checklist for coating-aware design:

- Threaded Holes: Will they be masked before coating, or re-tapped after? Masking adds cost, while re-tapping removes protection.

- Mating Surfaces: Do both surfaces truly need coating? Often, one can be masked to preserve clearance.

- Sharp Internal Corners: Prone to excessive buildup. Design with generous radii for uniform finish.

Your Interactive Decision Tool: The Material Selection Matrix

The material selection decision matrix is a powerful tool that transforms this complex process from an art into a science. It allows you to quantify your project’s priorities and systematically evaluate how well each candidate material meets them, creating a clear, data-driven rationale for your final choice.

The process is logical and straightforward:

- Define Criteria & Assign Weights: List all critical criteria (e.g., corrosion resistance, strength-to-weight ratio, cost). Assign a numerical weight to each (e.g., 1 to 5) to reflect its importance.

- Score Each Option: For each material, score how well it meets each criterion on a consistent scale (e.g., 1 to 5, where 5 is best), based on objective data.

- Calculate the Weighted Score: Multiply each score by its weight. Sum these to get a total for each material.

Worked Example: Designing a Rugged, Portable Marine-Grade Electronic Enclosure

| Criteria (Weight) | Anodized 5052 Aluminum | 316 Stainless Steel | Powder-Coated A36 Steel |

|---|---|---|---|

| Corrosion Resistance (5) | Score: 4 (Weighted: 20) | Score: 5 (Weighted: 25) | Score: 2 (Weighted: 10) |

| Low Weight (4) | Score: 5 (Weighted: 20) | Score: 2 (Weighted: 8) | Score: 2 (Weighted: 8) |

| Formability (3) | Score: 5 (Weighted: 15) | Score: 3 (Weighted: 9) | Score: 4 (Weighted: 12) |

| Impact Toughness (3) | Score: 3 (Weighted: 9) | Score: 4 (Weighted: 12) | Score: 5 (Weighted: 15) |

| Low Life-Cycle Cost (2) | Score: 4 (Weighted: 8) | Score: 3 (Weighted: 6) | Score: 2 (Weighted: 4) |

| TOTAL WEIGHTED SCORE | 72 | 60 | 49 |

In this analysis, Anodized 5052 Aluminum emerges as the clear winner, offering an excellent balance of properties for this specific application.

To empower your own projects, we have created a reusable template. Click here to download our free Material Selection Decision Matrix (Excel Template) and start making data-driven decisions today.

The Ultimate FAQ: Answering Your Toughest Material Selection Questions

- Can you truly “anodize” stainless steel? No, not in the traditional sense. Anodizing is an electrochemical process primarily for non-ferrous metals like aluminum. The acid baths used for aluminum will damage stainless steel. The colorful finishes on stainless steel are typically achieved through different processes like heat treatment or PVD coating.

- For general structural parts, what is the “safest” grade of carbon steel to specify? For most general fabrication, ASTM A36 or AISI 1018 are excellent, safe choices. Both are low-carbon steels known for their outstanding weldability and good formability, making them predictable, available, and cost-effective.

- When should I prioritize “Life Cycle Cost” over initial “Material Cost”? Prioritize Life Cycle Cost Analysis (LCCA) for any product intended for long-term service, especially in public infrastructure or harsh environments. A classic example is a public bridge railing. A painted carbon steel railing has a low initial cost but requires costly repainting. A stainless steel railing has a higher upfront cost but minimal cleaning over a 50-year lifespan, making it far more economical in the long run.

- How do I balance the trade-offs between strength, hardness, toughness, and ductility? These properties are often in opposition. The key is to identify the primary performance requirement for your application. A cutting tool needs maximum hardness, even if it means sacrificing some toughness. An automotive frame needs maximum toughness to absorb impact by deforming (ductility). Understanding that you cannot maximize all properties simultaneously is the first step to making an intelligent compromise.

Conclusion: Material Selection as a Cornerstone of Supply Chain Integrity

A successful custom metal fabrication project is the result of a holistic and rigorous material selection process. It demands a balance between performance, manufacturability, total cost of ownership, and the mitigation of hidden risks like galvanic corrosion.

By moving beyond simple upfront cost and adopting a systematic framework, you can transform material selection from a subjective art into a data-driven science. This approach leads to choices that are not only technically sound and economically prudent but also fully traceable and defensible.

If you are facing a complex material selection challenge for your next project, the experts at YISHANG are ready to provide the support and guidance you need.