Choosing the right steel grade is a critical decision for industrial procurement managers. The wrong material can result in missed deadlines, rising costs, or even equipment failure. In this guide, we compare two commonly specified steel types—A36 and AR500—to help you make informed, application-driven choices based on mechanical performance, fabrication needs, and total cost of ownership.

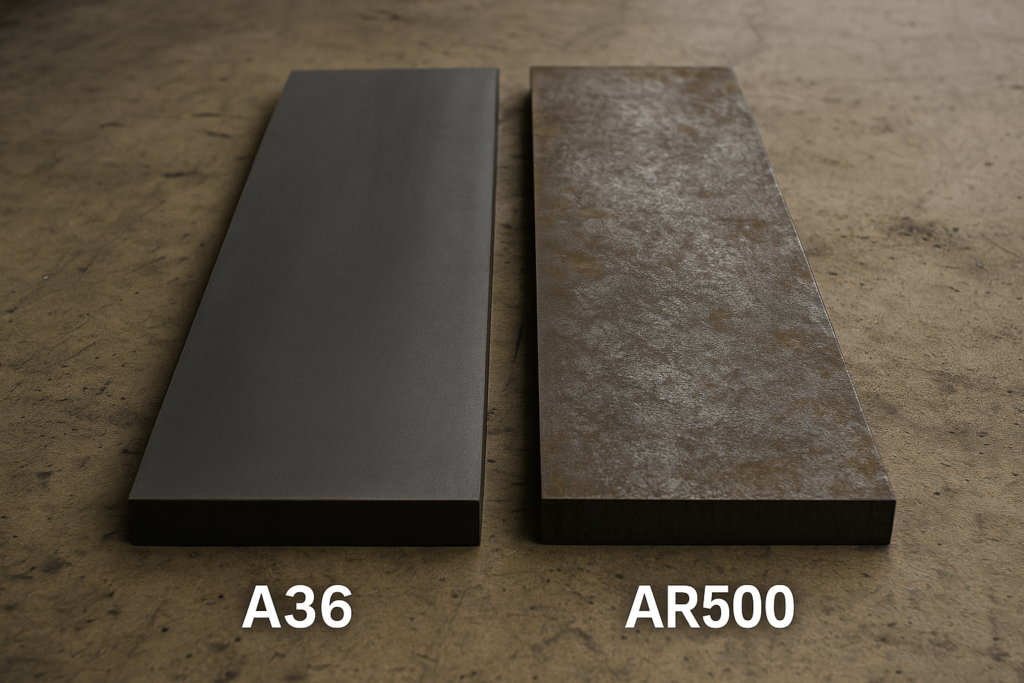

At a Glance: A36 vs. AR500 for Quick Decision-Making

For professionals who need to quickly assess material suitability, this table outlines the core differences.

| Decision Factor | ASTM A36 Steel | AR500 Steel |

|---|---|---|

| Primary Application | Structural & General Fabrication | High-Wear & Severe Impact Zones |

| Core Philosophy | Ductility (Bends before breaking) | Hardness (Resists surface damage) |

| Hardness (Brinell) | ~119-162 BHN | ~460-550 BHN |

| Weldability | Excellent, forgiving, minimal prep | Difficult, requires strict procedural control |

| Procurement Cost | Low initial cost per pound | High initial cost per pound |

| Bottom Line | The economical choice for building things that need to be strong and easily formed. | The performance choice for components that must endure extreme abrasion and impact. |

This overview provides a starting point. However, a truly strategic procurement decision requires a deeper understanding of the metallurgical and fabrication nuances that follow.

What the Designations “A36” and “AR500” Mean for Your Project

The names of these steels are not arbitrary; they are a form of engineering shorthand that immediately communicates their primary function and guaranteed properties—a crucial detail for compliance and quality assurance.

ASTM A36 is a standard governed by ASTM International. Its name is a direct reference to its most critical mechanical property for any structural engineer: a minimum yield strength of 36,000 pounds per square inch (psi), or 36 ksi. This value is the bedrock of structural safety calculations, guaranteeing the load at which the material begins to permanently deform.

In contrast, AR500’s name signals its primary function: Abrasion Resistance. The “500” refers to its nominal Brinell Hardness Number (BHN) of 500, a direct measure of its ability to resist surface indentation and scratching. While A36’s name guarantees its load-bearing strength, AR500’s name guarantees its surface durability.

The Core Trade-Off: Ductility vs. Hardness

Navigating the choice between A36 and AR500 steel means understanding a fundamental principle of metallurgy: the inverse relationship between ductility and hardness. Optimizing one almost always comes at the expense of the other.

A36 steel is engineered for ductility. Think of it as a material designed to fail safely. Under extreme stress, it will visibly bend, stretch, and deform long before it fractures, providing a critical warning in structural applications like buildings and bridges. This behavior is a result of its low carbon content and hot-rolled manufacturing process.

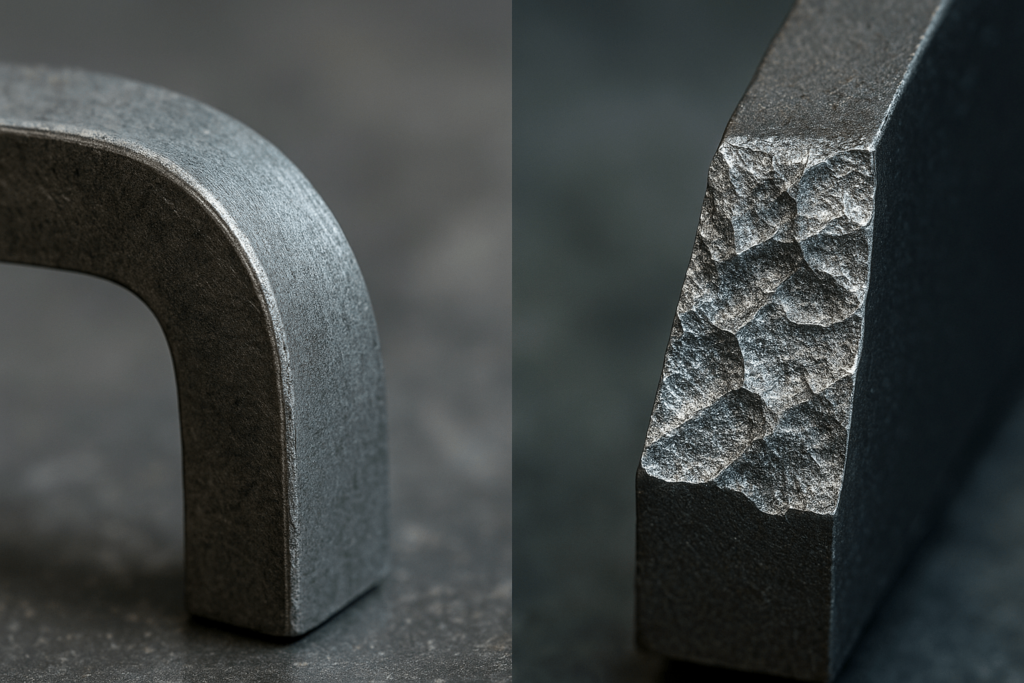

AR500 steel is engineered for hardness. It is a high-carbon alloy steel that undergoes a specialized quenching and tempering heat treatment. This process creates a rigid internal metallurgical structure (martensite) that is exceptionally resistant to surface wear. However, this hardness makes the material more brittle; when pushed past its limit, it is more likely to crack than to bend.

Application Analysis for Procurement Professionals

The most effective procurement decisions are application-driven. Matching the material’s core properties to the operational demands of the component is key to maximizing value and performance.

Structural Projects: Why A36 is the Industry Standard

For construction, machinery frames, and general fabrication, ASTM A36 is the default choice for sound engineering and economic reasons. Its predictable yield strength and high ductility are essential for structural safety.

From a procurement perspective, the benefits are clear. A36 is a widely available commodity, which ensures competitive pricing and stable supply chains. More importantly, its excellent weldability and machinability translate directly to lower production costs, faster fabrication times, and the ability to use standard equipment and labor.

High-Wear Environments: The Business Case for AR500

In industries like mining, aggregate, and heavy construction, component failure is measured in hours of costly operational downtime. This is where AR500 demonstrates its value. It is the specified material for wear liners, excavator buckets, dump truck beds, and industrial shredder components.

While the initial cost per pound for AR500 is significantly higher, its service life in high-abrasion environments can be many times that of A36. For a procurement manager, the calculation is simple: a 4x increase in initial material cost might prevent 11 equipment shutdowns for replacements, resulting in a dramatically lower total cost of ownership (TCO) and a significant boost to operational uptime.

A Note on Ballistic Applications

The performance difference is most extreme in ballistic applications. A36 steel is dangerously unsuitable for shooting targets, as its soft surface craters upon impact, creating unpredictable and hazardous ricochets.

AR500, due to its extreme hardness, is the safe industry standard. It shatters projectiles into low-energy fragments, known as spatter, preventing penetration and dangerous bounce-back. This ensures a safe and durable target solution.

The Fabricator’s Playbook: Production and Cost Implications

For a wholesale buyer, understanding how a material behaves on the shop floor is critical. Fabrication challenges directly translate to higher costs and longer lead times.

Welding: Forgiving vs. Finicky

Welding A36 is a straightforward, low-cost process. Its low carbon content makes it highly forgiving, allowing for fast, strong welds with standard consumables and minimal preparation.

Welding AR500 is a specialized, technical process that requires strict procedural control to avoid catastrophic failure. The high carbon content makes it susceptible to hydrogen-induced cracking in the heat-affected zone (HAZ)—the area adjacent to the weld that is altered by heat.

Successfully welding AR500 involves:

- Mandatory Preheating: The plate must be preheated to around 100°C (212°F) to slow the cooling rate and prevent brittle microstructures.

- Low-Hydrogen Consumables: Using filler metal like an E7018 electrode is essential to minimize hydrogen, a primary cause of cracking.

- Controlled Cooling: The welded part must be cooled slowly, often wrapped in insulating blankets, to reduce thermal stress.

These extra steps require more skilled labor, specialized equipment, and significantly more time per part—a critical factor in any production cost analysis.

Cutting: Speed vs. Precision vs. Integrity

A36 can be cut efficiently with any standard method, including plasma, oxy-fuel, or saws.

Cutting AR500 involves a trade-off between speed, precision, and preserving the material’s properties:

- Plasma Cutting: Fast and effective, but creates a larger HAZ, which can soften the material along the cut edge.

- Waterjet Cutting: A “cold cutting” process that creates no HAZ, preserving hardness to the edge. Highly precise but slower.

- Fiber Laser Cutting: Balances precision with minimal HAZ, ideal for complex parts where material integrity matters.

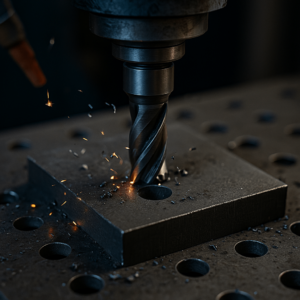

Drilling, Machining, and Forming

The difference in production continues with machining. A36 can be easily drilled and milled with standard high-speed steel (HSS) tooling.

Attempting to machine AR500 with HSS tools will result in immediate tool failure. It requires solid carbide tooling, rigid machine setups, and very slow speeds, increasing both tooling costs and cycle times per part.

Similarly, A36’s ductility allows it to be easily bent into tight radii. Forming AR500 is severely restricted and requires a very large bend radius (often 10 times the plate thickness) to prevent cracking.

Procurement & Value Analysis: A36 vs. AR500

A strategic procurement decision goes beyond the initial price quote. It involves a comprehensive analysis of the total cost of ownership.

Initial Investment: Price Per Pound

There is no ambiguity here: A36 is one of the most economical steel plates available due to its simple composition and high-volume production.

AR500 is a premium, specialty product. Its complex recipe of alloys and its energy-intensive heat treatment process make it inherently more expensive to produce, resulting in a significantly higher cost per pound.

The Real ROI: A Total Cost of Ownership Example

Consider a wear liner in a mining chute, a component that is critical to a multi-million dollar operation.

- Scenario A (A36 Liner): Initial cost is $1,000. Due to the highly abrasive ore, it fails and requires replacement every 3 months. Each replacement requires 8 hours of downtime, costing the operation $80,000 in lost production.

- Scenario B (AR500 Liner): Initial cost is $4,000. Due to its extreme hardness, it lasts for 36 months.

Over a three-year period, the A36 liner would cost $12,000 in material plus a staggering $880,000 in downtime costs, for a TCO of $892,000. The AR500 liner, with no replacements needed, has a TCO of just $4,000. This stark example illustrates why, for the right application, the more expensive material is overwhelmingly the more profitable choice.

Frequently Asked Questions (FAQ) for Professional Buyers

- Can you weld A36 steel to AR500 steel? Yes, but the procedure must follow AR500’s requirements, including preheating and using a low-hydrogen filler metal. Sometimes, a filler metal with A36 strength is chosen to create a more ductile joint.

- How can you identify the difference without a Mill Test Report? A simple hardness test is the most reliable field method. A standard HSS drill bit can easily cut A36 but will skate over AR500’s surface and dull quickly.

- Is AR500 steel bulletproof? More accurately, it’s bullet-resistant. Its effectiveness depends on plate thickness and projectile type. It is designed to stop standard lead-core bullets, not specialized armor-piercing rounds.

- Does AR500 steel rust? Yes. AR500 is a carbon alloy steel and lacks chromium, so it needs protective coating for outdoor use.

- Which is “stronger,” A36 or AR500? AR500 has higher tensile and yield strength. However, A36 offers better ductility and energy absorption, which is also a form of strength in structural applications.

The Final Verdict: Making the Right Procurement Decision

The choice between ASTM A36 and AR500 is not about selecting a “better” material, but matching engineered properties to the specific needs of your project.

Choose ASTM A36 when structural integrity, ease of fabrication, and low cost are priorities. It’s the practical choice for general manufacturing and construction.

Choose AR500 when extreme abrasion or impact resistance is critical. It delivers exceptional value through durability and uptime.

At YISHANG, we specialize in custom and bulk fabrication of steel components including A36 and AR500. Contact our engineering team for specifications, volume pricing, and manufacturing support tailored to your project.