Introduction: The Art and Science of Joining Metal Without Melting It

In global sheet metal fabrication, the integrity of a joint defines product performance. While welding dominates many production lines, a more controlled and precise process often proves better for assembly consistency and part quality: torch brazing.

Torch brazing creates permanent bonds between metals—without melting the base materials. It works through metallurgical principles that produce joints stronger than the surrounding metal, making it ideal for precision applications.

This guide is engineered for industrial professionals—OEM procurement managers, mechanical engineers, and production supervisors—who need more than surface-level advice. It offers actionable guidance on specifying filler metals, selecting equipment, minimizing defects, and integrating brazing into real-world workflows.

Part 1: The Core Concepts – Why Brazing is a Strategic Manufacturing Choice

Understanding the fundamentals of torch brazing is essential for informed process selection and RFQ specifications. This section outlines what torch brazing is, how it compares to other joining techniques, and why it’s particularly effective for joining dissimilar metals.

1.1 Torch Brazing Explained: A Metallurgical Bond

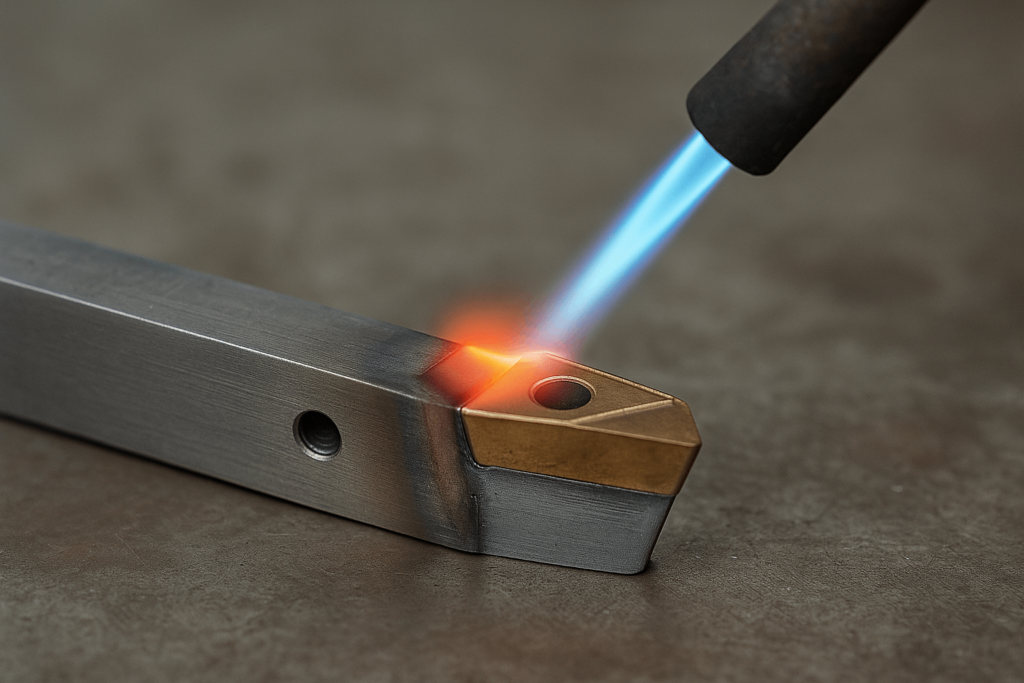

Torch brazing uses a focused flame to heat closely fitted metal parts above 840°F (450°C), without melting the base metals. A specially designed filler metal, with a lower melting point, is introduced into the joint area.

As it melts, capillary action draws the filler metal into the narrow gap between parts. As it cools, the filler solidifies and forms a sealed, metallurgically bonded joint.

Unlike surface adhesives or mechanical fasteners, brazing produces a continuous bond that is both chemically and physically integrated. This allows for both small-batch manual operations and scalable automated lines.

1.2 Brazing vs. Welding vs. Soldering: A Strategic Comparison

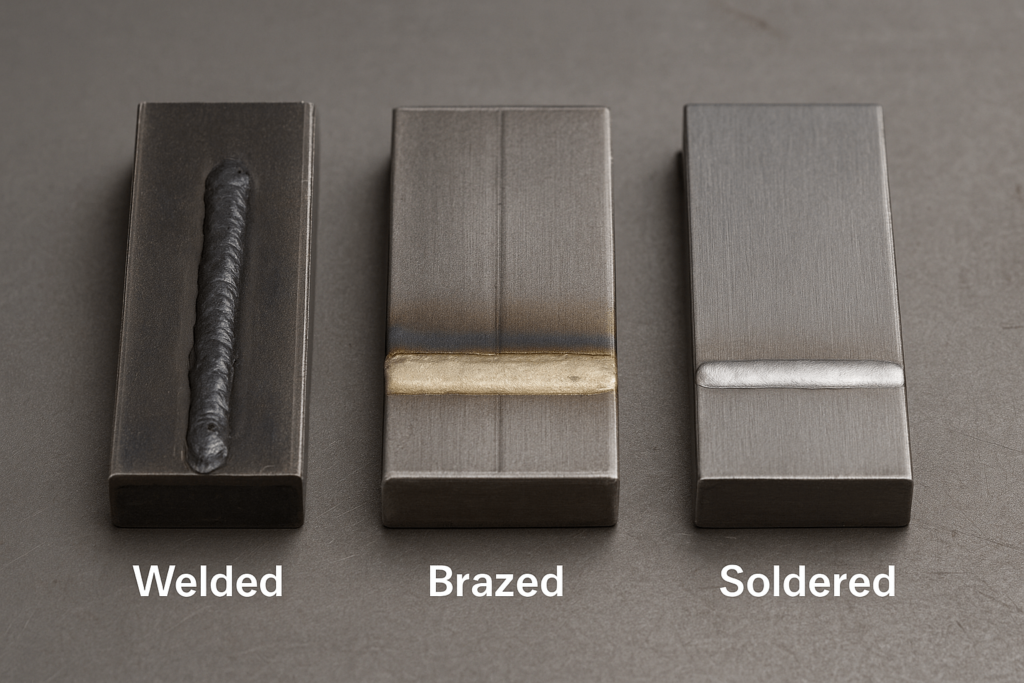

Choosing the right joining method affects everything from cycle time to downstream tolerances. Understanding brazing vs. welding vs. soldering helps ensure alignment between design intent and production reality.

- Welding: Fuses base metals, ideal for high structural loads. Risks warping, especially with thin or dissimilar materials.

- Soldering: Operates at lower temperatures, ideal for electronics. Insufficient for mechanical strength applications.

- Brazing: Uses lower heat than welding, minimizing distortion and enabling multi-metal joints.

| Characteristic | Welding | Brazing | Soldering |

|---|---|---|---|

| Temperature | Very High (>2,500°F) | High (>840°F) | Low (<840°F) |

| Base Metal State | Melted & Fused | Solid (Not Melted) | Solid (Not Melted) |

| Joint Strength | Strongest | Strong | Weakest |

| Key Advantage | Structural integrity | Low distortion; dissimilar materials | Minimal heat for sensitive components |

| Typical Use | Structural frames | HVAC, metal tools, copper-steel assemblies | Circuit boards, connectors |

1.3 The Science Behind the Bond: Capillary Action

The strength of brazed joints comes from capillary action—the tendency of liquid metal to flow into narrow gaps between solid surfaces. This action is driven by the balance between adhesive and cohesive forces.

Three conditions must be met:

- Uniform Heating: Ensures full activation of the filler.

- Clean Metal Surfaces: Prevents oxide layers from blocking flow.

- Controlled Joint Clearance: 0.001–0.005 inches for optimal wicking.

Understanding these fundamentals helps prevent common quality failures.

Part 2: Your Torch Brazing Toolkit – Specifying Equipment and Materials

Torch brazing depends on precise control of every variable—gas source, joint design, filler alloy, and flux type. This section details the specifications engineers and buyers must consider to achieve consistent, repeatable quality.

2.1 Choosing Your Flame: Torch & Fuel Selection

The torch and fuel gas determine flame temperature and characteristics:

- Oxy-acetylene: Reaches 6,300°F. Ideal for steel but requires experienced handling.

- Air-acetylene: Gentler flame (~3,000°F). Preferred for copper, brass, and heat-sensitive parts.

A neutral flame is essential for most jobs. Avoid oxidizing flames, which can degrade joint quality. Use carburizing flames selectively for copper-rich alloys.

2.2 The Heart of the Joint: Choosing Brazing Rods

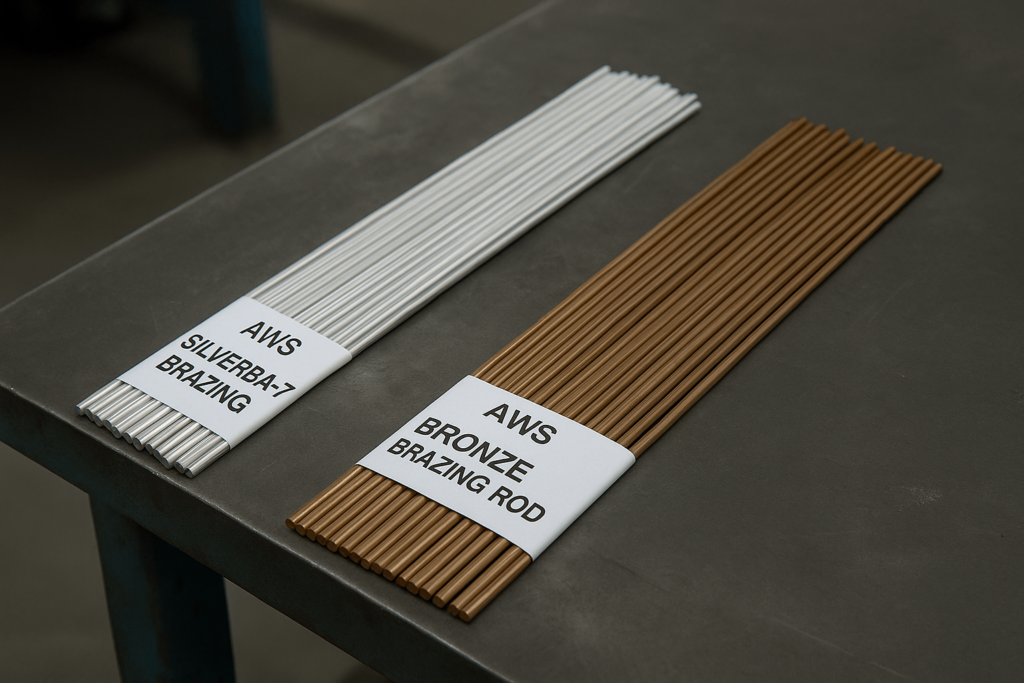

Filler metal choice determines joint strength, corrosion resistance, and metallurgical compatibility. Reference AWS designations when selecting:

- BAg (Silver Alloys): For copper to steel or stainless. Excellent flow and strength.

- BCuP (Copper-Phosphorus): For copper-to-copper joints only. Self-fluxing. Do not use on steel.

- BAlSi (Aluminum-Silicon): For aluminum assemblies; requires close heat control.

| Base Metal 1 | Base Metal 2 | Recommended AWS BFM Class(es) | Key Considerations |

|---|---|---|---|

| Copper | Steel / Stainless Steel | BAg (e.g., BAg-24) | Use silver flux. Never specify BCuP alloys. |

| Copper | Copper | BCuP (e.g., BCuP-2) or BAg | Self-fluxing; reduces cost and steps. |

| Aluminum | Aluminum | BAlSi (e.g., BAlSi-4) | Requires aluminum flux; control temperature precisely. |

| Steel | Tungsten Carbide | BAg (e.g., BAg-22 with Ni) | Use boron-modified black flux for oxidation protection. |

2.3 Why Flux Matters More Than You Think

Flux prevents oxidation and ensures proper filler wetting. Matching flux to material and heating time is critical.

- Silver flux: Versatile; suited for most copper/steel jobs.

- Black flux (boron-based): For prolonged heating or stainless steel.

Ensure flux temperature range overlaps with filler metal working temperature.

Part 3: The 7-Step Brazing Process – From Prep to Perfection

Follow this sequence to standardize quality across batches:

- Design Joints for Fit-Up: Lap joints preferred. Clearance: 0.001–0.005 in.

- Surface Prep: Degrease + remove oxides via mechanical or chemical means.

- Apply Flux: Uniform coating prevents oxidation.

- Assemble Securely: Fixtures must hold parts stable during heating.

- Heat Evenly: Sweep flame across the joint, focusing on base metals.

- Introduce Filler: Let the heated base metal draw in the alloy.

- Post-Braze Cleaning: Quench in water, scrub away flux residues.

Part 4: Troubleshooting – Diagnosing & Fixing Defects

Even with good prep, issues may arise. Use this matrix to identify problems and corrective actions:

| Defect | Visual Indicators | Root Cause | Fix |

|---|---|---|---|

| Lack of Wetting | Filler beads up, doesn’t flow | Dirty joint; low heat; wrong flux | Clean surface; heat evenly; reapply flux |

| Porosity | Tiny voids | Gas entrapment; overheating | Lower heat; better cleaning/prep |

| Cracks | Hairline splits post-cooling | Rapid quench; incompatible filler | Cool slowly; re-evaluate alloy choice |

| Distorted Joint | Rough finish; weak adhesion | Movement during solidification | Improve fixturing; reduce vibration |

Part 5: Real-World Applications – Brazing in Action

5.1 HVAC/R Systems

Brazing is standard for sealing refrigerant copper tubing. Nitrogen purging during brazing prevents internal scale buildup.

5.2 Aerospace & Automotive

Critical components like heat exchangers and sensor housings often require copper-to-aluminum or copper-to-steel joints. NADCAP-compliant brazing may be required.

5.3 Carbide Tools & Metal Frames

Brazing joins tungsten carbide to steel with minimal stress concentration. It also applies in custom sheet metal frames that demand strength without distortion.

Part 6: Safety First – Torch Brazing Safety Checklist

- PPE: Wear ANSI Z87.1 eye protection, gloves, and flame-retardant clothing.

- Ventilation: Use local exhaust ventilation for flux fumes.

- Gas Cylinder Protocol: Store upright, away from ignition sources.

Part 7: The Future of Brazing – Beyond the Torch

Advanced methods supplement—but do not replace—torch brazing:

- Induction Brazing: Fast, contactless, suited for automation.

- Laser Brazing: High-precision, low-distortion, used in EV battery pack production.

Torch brazing remains essential for low-volume runs, prototypes, and structural assemblies involving dissimilar metals.

Part 8: Partnering with YISHANG – Your Industrial Brazing Supplier

YISHANG supports global OEMs with over 26 years of experience in custom metal fabrication, including torch brazing. Our ISO 9001-certified factory delivers:

- Manual and automated brazing lines

- Expertise in copper, stainless, aluminum

- OEM/ODM support across HVAC, tools, architecture, and more

Whether you require precision brazing for prototypes or production-scale output, we help reduce rework, improve first-pass yield, and accelerate your lead times.

Contact YISHANG today to explore how our brazing services can optimize your manufacturing results.