Introduction: Solving the “Impossible” Design Challenge

Engineers and procurement managers often face a critical challenge: a complex component design that seems impossible to manufacture within budget and specifications.

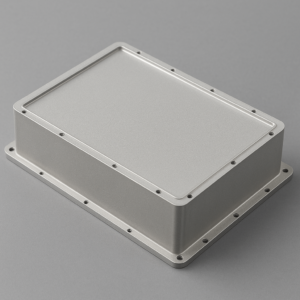

Consider a lightweight, aerospace-grade electronic enclosure. It requires dozens of thin internal walls for EMI shielding and a network of intricate, hermetically sealed channels for liquid cooling.

Conventional welding would warp the thin-walled aluminum. Machining from a monolithic block would be astronomically expensive. How do you bridge the gap between an ambitious design and a manufacturable, cost-effective reality?

The solution is a sophisticated joining process: Dip Brazing. This guide explores the design philosophy that makes complex, high-performance aluminum assemblies possible, offering a strategic advantage for demanding precision sheet metal projects. We’ll also outline how to specify dip brazing as part of your RFQ process, reduce TCO, and qualify the right suppliers.

1. The Science of Dip Brazing: A Look Inside the Molten Bath

At its core, dip brazing is a process where an entire assembly is submerged in a molten salt bath, allowing a specialized filler metal to join every seam simultaneously.

To understand this, consider three key elements working in synergy: the base aluminum alloy parts (the structural skeleton), the filler metal (a metallurgical adhesive with a lower melting point), and the molten salt bath.

This bath is the key. It’s not just a heat source; it’s a chemically active flux that cleans the metal surfaces. This allows the filler metal to flow into every microscopic gap through a powerful force known as capillary action.

The result is not just a series of connections, but a single, unified component. Unlike fusion welding, dip brazing operates at a lower temperature, preserving the integrity of the parent materials and ensuring minimal thermal distortion.

2. The Dip Brazing Playbook: A Four-Act Journey to a Monolithic Masterpiece

Transforming individual parts into a high-integrity assembly is a meticulously controlled, multi-stage ritual. For sourcing professionals, understanding these dip brazing process steps is key to evaluating supplier capability and quality control.

Step 1: The Purity Ritual (Cleaning & Preparation)

The journey begins with an uncompromising commitment to cleanliness. Every trace of oil, grease, and the natural aluminum oxide layer must be chemically stripped from the components.

This is more than simple washing; it’s creating a surgically pure surface. Even a fingerprint can contain enough contaminants to compromise a joint’s integrity. This multi-stage cleaning ensures a flawless metallurgical bond.

Step 2: The Architectural Blueprint (Precision Assembly & Fixturing)

With chemically pure components, the next stage is careful assembly. This is where smart design for manufacturability (DfM) significantly impacts the total cost of ownership.

The most efficient assemblies use self-jigging features, like interlocking tabs, which precisely locate parts without expensive external fixtures. The filler metal—as a wire, paste, or clad layer—is then strategically placed at each joint.

Step 3: The Thermal Journey (Preheating & Immersion)

The assembly then begins its thermal journey, starting with a slow preheat in a circulating air furnace to around 1,025°F (552°C).

This crucial step prevents thermal shock and drives off any residual moisture, which could be hazardous in the salt bath.

Once preheated, the assembly is carefully lowered into the molten salt bath, maintained at an extremely precise temperature, typically around 1,095°F (590°C). Immersion is brief, usually 60 to 120 seconds.

In this short window, the molten salt flux dissolves any oxides, the filler metal melts, and capillary action pulls the liquid alloy into every joint, forming a perfect bond across the entire assembly.

Step 4: The Final Refinement (Cooling & Flux Removal)

After immersion, the assembly is withdrawn and the filler metal solidifies. The final step is one of the most critical for long-term reliability: the complete removal of all residual salt flux.

The chloride-based salts are corrosive to aluminum. Any residue can attract moisture and cause failure over time. The rigorous cleaning process ensures the part’s long-term performance and dimensional stability.

3. The Strategic Choice for Procurement: When to Specify Dip Brazing

Choosing the right joining process is a critical procurement decision that impacts cost, performance, and lead times. Dip brazing is not a universal solution, but for the right application, its advantages are substantial.

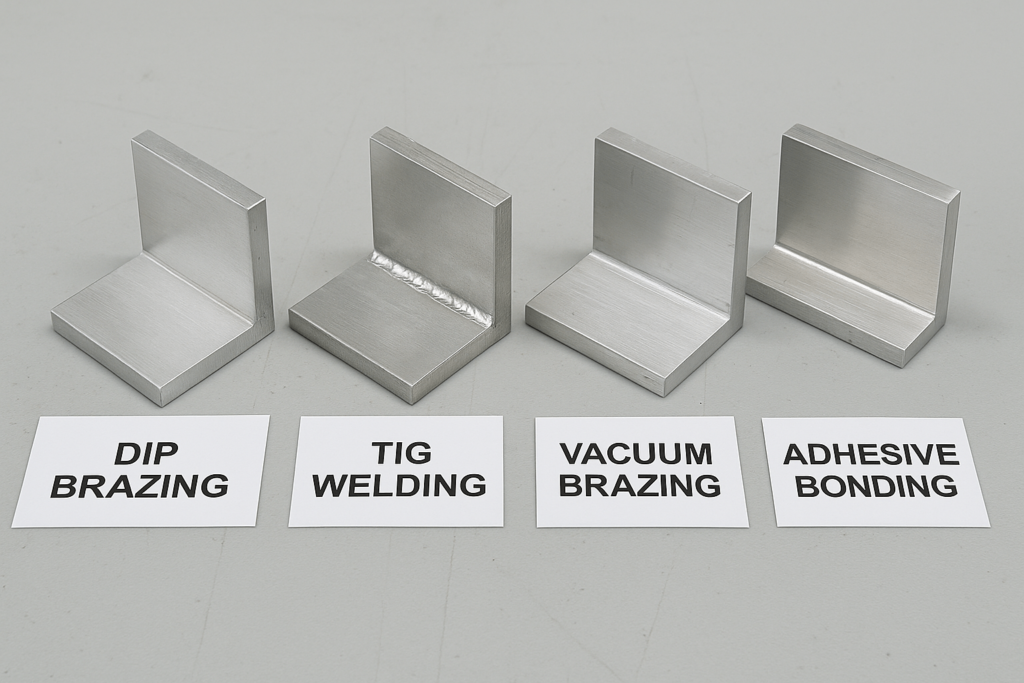

3.1. Dip Brazing vs. TIG/MIG Welding: Heat Management & Dimensional Stability

TIG welding uses an intense, localized heat source to melt the base metals together. This creates extreme thermal gradients, known for causing warping in thin-walled aluminum. Post-weld rework and fixturing add cost and cycle time.

Dip brazing, in contrast, heats the entire assembly uniformly. This virtually eliminates thermal distortion and allows for tighter tolerances—ideal for complex or tightly nested aluminum enclosures.

3.2. Dip Brazing vs. Vacuum Brazing: Internal Complexity Advantage

Vacuum brazing eliminates the need for chemical flux, producing ultra-clean joints in controlled environments. But it’s best suited to parts with simpler, open geometries.

Dip brazing, with its molten salt bath, enables joining of internal channels, blind cavities, and nested structures. For dense assemblies or EMI-sealed enclosures, it provides more geometric freedom and cost-efficiency.

3.3. Joining Process Comparison: A Procurement Reference Table

| Parameter | Dip Brazing | TIG/MIG Welding | Vacuum Brazing | Adhesive Bonding |

|---|---|---|---|---|

| Thermal Distortion | Low | High | Very Low | None |

| Assembly Complexity | Excellent | Poor | Good | Excellent |

| Joint Accessibility | Internal and blind joints OK | Line-of-sight only | Limited by gas path | Surface contact only |

| Conductivity (Thermal/Electric) | Excellent | Good | Excellent | Poor |

| TCO for Complex Parts | High ROI | High (labor + rework) | High (equipment cost) | Moderate (variable) |

| Ideal Use Cases | EMI shields, heat exchangers | Frames, brackets | Clean aerospace components | Plastics, dissimilar materials |

4. Real-World Applications & Supplier Qualification Signals

The true value of dip brazing is demonstrated in the advanced applications it enables. In sectors like aerospace, medical, and telecommunications, dip brazing is a signal of high-performance, reliable engineering.

Application: EMI-Sealed Aerospace Electronics

In military and aerospace systems, an avionics enclosure must shield sensitive electronics from electromagnetic interference (EMI).

Dip brazing creates a continuous, gap-free metallurgical seal around the entire housing. This results in unmatched EMI performance, especially when compared to mechanical fastening.

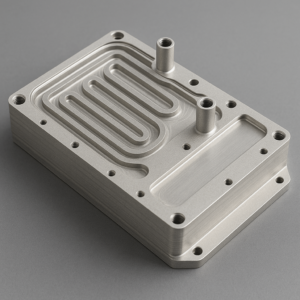

Application: High-Efficiency Liquid Cooling Plates

High-power electronics demand thermal management. Dip brazing enables liquid cooling channels to be enclosed with hundreds of thermally conductive joints formed simultaneously. The result: minimal resistance, no warping, and excellent repeatability in production.

Application: Microwave-Precision Waveguide Assemblies

For radar, satellite, or 5G applications, signal quality depends on internal surface geometry. Dip brazing allows waveguides and antennas to be formed from multiple machined parts into a seamless, electrically consistent unit—impossible to achieve with adhesives or point welds.

5. Design for Manufacturability (DfM): Reduce RFQ Risk & Lead Time

A successful dip brazed assembly is born on the design table. Involving your OEM supplier early reduces iterations and cost.

- Favor Lap Joints: Stronger, more reliable, easier to braze consistently.

- Avoid Blind Cavities: Ensure the salt can flow in and drain freely.

- Use Self-Jigging Tabs: Speeds up assembly, reduces fixturing cost.

- Respect Capillary Gaps: Target 0.001–0.010 in. for optimal filler flow.

- Balance Mass: Avoid clustering thick + thin parts to minimize distortion.

These practices help avoid costly design changes post-quote, shorten production timelines, and ensure yield consistency.

6. Quality Standards: What Procurement Should Ask For

Dip brazing is often part of a mission-critical supply chain. Buyers should confirm that their supplier complies with relevant standards:

- Nadcap Accreditation (aerospace process auditing)

- AS9100 Quality System (aerospace/defense grade manufacturing)

- AWS C3.7/C3.7M Spec Compliance (aluminum brazing process control)

These certifications ensure your vendor maintains traceable processes, documented inspections, and repeatable quality.

7. Environmental Considerations & Future of Dip Brazing

Molten salt processes carry environmental implications—mainly due to waste salt, chemical cleaning, and vapor hazards.

The industry is evolving toward:

- Non-Corrosive Fluxes: Lower residue, easier post-cleaning.

- Precision Flux Application: Minimal consumption, cleaner outputs.

- Flux-Cored Filler Wire: Built-in flux = less waste and overspray.

Buyers should ask vendors about their compliance with RoHS/REACH, salt disposal protocols, and future-proof process upgrades.

Conclusion: Strategic Sourcing Advantage with Dip Brazing

Dip brazing offers a powerful combination of structural integrity, precision, and material compatibility—especially for aluminum assemblies where welding fails.

When properly designed, dip brazed components reduce rework, improve reliability, and simplify multi-part constructions. This is especially relevant for OEMs and industrial buyers balancing design intent with long-term performance.

As a RoHS- and ISO 9001-certified supplier serving 50+ countries, YISHANG brings 26+ years of experience in aluminum fabrication, welding alternatives, and custom assemblies.

📩 Let’s talk: Our engineering team is ready to support your next dip brazing project with DfM insight, fast sampling, and export-ready batch production.