Introduction: The Unsung Hero—How a Simple Washer Prevents Catastrophic Failure

In global manufacturing, a component’s failure is measured in warranty claims, production halts, and reputational damage. Surprisingly, the root cause often isn’t a major part, but a component as seemingly minor as a washer.

Although frequently seen as a low-cost commodity, the washer is, in fact, a critical engineering device. It serves as the silent guardian of bolted joint reliability, ensuring performance and safety across industrial washer applications, including automotive and construction sectors.

Therefore, this guide provides deep technical insights that procurement professionals and design engineers require for informed sourcing. Instead of simply listing parts, we explore the science of connection, offering actionable knowledge for selecting the ideal washer solution in real-world scenarios.

Chapter 1: Beyond the Basics—What “Invisible” Problems Do Washers Actually Solve?

Understanding Functional Challenges in Bolted Joints

For a procurement specialist, understanding what washers are for is key to sourcing the right part and avoiding costly specification errors. Notably, a washer’s function involves a combination of interface controls, each addressing potential failure points in a fastener assembly.

1.1 The Problem: My Fastener is “Eating” My Material!

When a high-strength steel bolt is tightened onto a softer material like an aluminum chassis, concentrated pressure causes yielding and deformation. Consequently, this is where a washer’s function—load distribution—becomes essential.

A washer acts like a snowshoe, dramatically increasing the bearing surface area. As a result, it disperses the clamping force, reducing surface pressure. This prevents pull-through failure in thin sheet metal and cracking in plastics, preserving the integrity of the assembly.

1.2 The Problem: Tightening the Nut Scratched the Surface!

Tightening a nut involves rotational force. Without a barrier, this motion can scratch or gall the surface, compromising protective coatings and inviting corrosion.

A hardened steel washer provides a smooth, stationary surface for the fastener to turn against. This ensures surface protection and allows accurate torque application without cosmetic or structural damage—a vital consideration in high-finish products.

1.3 The Problem: My Bolts Keep Vibrating Loose!

In dynamic environments like industrial machinery, vibration is the constant enemy of bolted joints. It causes gradual tension loss and eventual failure.

To solve this, specialized spring washers introduce elasticity into the joint. Consequently, they help maintain preload under vibration or thermal cycling, securing long-term reliability.

1.4 The Problem: I Need a Waterproof / Insulated Connection!

In some cases, a fastener must pass through a panel without permitting liquid leakage or electrical current transfer. Therefore, washers designed for sealing and isolation are indispensable.

Bonded sealing washers provide high-pressure, leak-proof seals. Meanwhile, shoulder washers made from nylon isolate metal screws from chassis, preventing electrical shorts.

Chapter 2: A Practical Guide to Washer Types: Finding the Best Partner for Your Project

Overview of Common Industrial Washer Types

Now that we’ve explored the challenges washers solve, it’s time to examine washer types. Each type serves a distinct purpose, and selecting the correct one remains a key engineering and sourcing decision.

2.1 The Foundational Players: The Plain Washer Family

Plain washers, or flat washers, are the most common. They provide load distribution and surface protection. Governed by standards such as ISO 7089 and DIN 125, they ensure consistency across global supply chains.

- Standard Flat Washers: Flat discs used in general applications to increase bearing surface.

- Fender Washers: With larger outer diameters (OD), they spread force over wide areas. As such, they are ideal for thin sheet metal. This makes them the best washer type for sheet metal.

- USS vs. SAE: Under ASME B18.22.1, USS washers have larger OD for construction; SAE are smaller and fit tight automotive spaces.

| Bolt Size | Pattern | ID (in) | OD (in) | Primary Use |

|---|---|---|---|---|

| 1/4″ | SAE | ~0.281 | 0.625 | Automotive, tight clearances |

| USS | ~0.312 | 0.734 | Construction, high load distribution | |

| 3/8″ | SAE | 0.406 | 0.812 | Machinery in compact spaces |

| USS | 0.438 | 1.000 | Structural joints, woodworking |

2.2 The Point of Contention: The Truth About Lock Washers

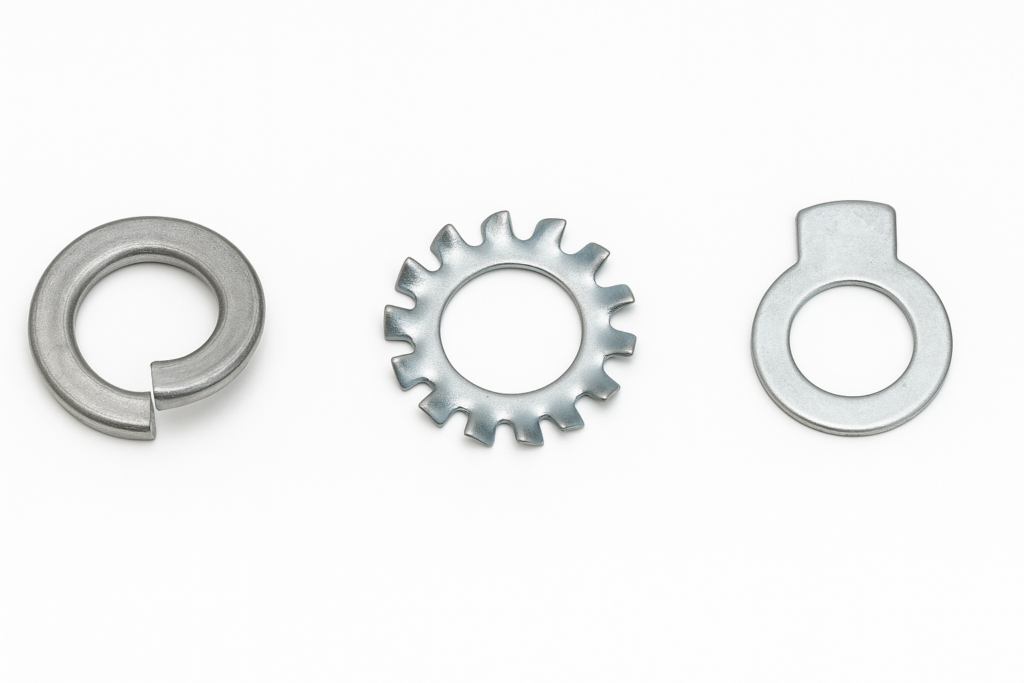

Lock washers are designed to stop loosening, but their effectiveness—especially split types—is highly debated.

- Split Lock Washers: The helical spring design appears logical. However, once torqued, they flatten and lose spring function.

- NASA’s Take: The NASA Fastener Design Manual (RP-1228) calls them “useless for locking.” This conclusion has led many industries to replace them.

- Effective Alternatives: Instead, Toothed Lock Washers grip surfaces. Tab Washers physically engage the nut or bolt to prevent rotation.

2.3 The Dynamic Masters: Spring Washers

Spring washers introduce elasticity, making them vital in vibration-prone or thermally cycled assemblies.

- Belleville Washers: Governed by DIN 2093, these precision springs can be stacked for specific load profiles.

- Wave Washers: They offer a gentler spring force—ideal for bearing preload and vibration damping.

2.4 The Specialist Operatives: Washers for Unique Challenges

This category features washers with unique geometries or materials.

- Sealing Washers: Combine metal rings and rubber to form leak-proof seals.

- Finishing Washers: Provide aesthetic flush finishes in visible areas.

- Shoulder Washers: Their “top-hat” shape offers electrical insulation and separation.

Chapter 3: Material Science: Choosing the Right “Armor” for Your Washer

Washer Material Selection for Industrial Use

Selecting the right material affects strength, corrosion resistance, and cost. This decision is particularly crucial when sourcing custom washer manufacturer solutions or OEM washer supply.

3.1 The Steel Standoff: Carbon Steel vs. Stainless Steel

- Carbon Steel: Strong and affordable but needs coating.

- Stainless Steel (304 vs. 316): 304 is general-purpose. 316 resists chemicals and salt, making it essential for marine use. Buyers often compare stainless steel washer vs zinc plated washers at this stage.

3.2 The Lightweight Champions: Aluminum, Copper & Brass

- Aluminum: Lightweight, corrosion-resistant, used in aerospace and transportation.

- Copper & Brass: Copper seals well due to softness. Brass adds strength and corrosion resistance, great for plumbing and terminals.

3.3 The Power of Non-Metallics: Nylon & Rubber

- Nylon: Electrically insulating and vibration-dampening.

- Rubber (EPDM vs. Neoprene): EPDM suits outdoor use; Neoprene resists oils and chemicals.

3.4 The Final Defense: Surface Coatings

- Zinc vs. Hot-Dip Galvanizing (HDG): Zinc is thin, cost-effective for dry areas. HDG is thicker and more corrosion-resistant.

- Black Oxide: Provides basic rust resistance with aesthetic appeal.

Chapter 4: The Expert’s View: The Bolted Joint Physics Your Competitors Don’t Know

Real-World Engineering Lessons from Fastener Failures

Understanding bolted joint dynamics is essential for selecting the correct washer—not just relying on specs.

4.1 Preload: The Invisible Clamp

Preload holds joints together. It’s created by bolt tension and prevents shear or loosening.

4.2 Embedding Relaxation

Surface imperfections compress under load. This shortens joint length and reduces preload—by up to 50%.

4.3 The Washer Paradox

Washers add interfaces that may relax under load. In stiff joints, flanged bolts often perform better.

Chapter 5: The Ultimate Selection Checklist and FAQ

OEM Washer Sourcing Checklist

- Analyze joint softness and need for distribution.

- Match materials to environment.

- Choose effective locking methods.

- Account for insulation or sealing needs.

- Evaluate flanged alternatives.

Frequently Asked Questions (FAQ)

🔹 Q: Can lock washers be reused?

A: Split types can be reused, but their performance degrades. Toothed types are single-use.

🔹 Q: Flat vs. Fender Washer?

A: Fender washers spread load better—best for thin materials.

🔹 Q: When NOT to use a washer?

A: In short, stiff joints where flange heads offer better results.

🔹 Q: Washer orientation?

A: Place rounded edge down to minimize friction.

🔹 Q: How many per bolt?

A: Use one under both bolt head and nut if they contact soft surfaces.

Why Choose a Custom OEM Washer Supplier?

At YISHANG, we understand the importance of specifying the right components. With over 26 years in OEM metal manufacturing and full ISO 9001 & RoHS compliance, we deliver reliable, customizable washer solutions across industries—from automotive to renewable energy.

For industrial washer applications or large-scale sourcing, contact our technical team. We are ready to support your project with expert advice and high-performance components. Partner with a trusted OEM washer supplier to source with confidence.