For procurement specialists, engineers, and product designers, selecting the right surface finish is a critical decision that impacts durability, aesthetics, and cost. Anodized aluminum stands out as a premium finishing choice, but navigating its complexities is key to successful large-scale production.

This guide provides the technical insights necessary for making informed purchasing decisions. We move beyond the basics to address the core challenges that matter most to wholesale buyers: ensuring batch-to-batch color consistency, correctly specifying finishes on technical drawings, and understanding the performance trade-offs that influence long-term value.

Whether you’re seeking industrial anodizing services for architectural frameworks, sourcing custom anodized aluminum parts from a trusted anodized aluminum supplier, or evaluating long-term color retention in large-volume manufacturing, this resource consolidates the key factors impacting quality, performance, and consistency.

1.0 The Fundamental Principle: Why Anodized Finishes are “Grown,” Not Coated

Understanding the anodizing process is the first step in appreciating its value. Unlike paints or powder coatings, which are additive layers applied to a substrate, an anodize finish is a conversion coating. The process does not add a separate layer; it electrochemically converts the surface of the aluminum itself into a hard, durable layer of aluminum oxide.

This integral layer is grown directly from the base aluminum, making it physically impossible to chip, flake, or peel. The resulting aluminum oxide is exceptionally hard—approaching the hardness of sapphire—and features a highly organized, porous structure.

It is this porous nature that allows the alu anodized material to be dyed. The color becomes embedded deep within the protective oxide layer before being permanently sealed. This fundamental difference is why an anodized aluminum finish offers superior abrasion resistance and longevity compared to surface-level treatments.

2.0 Color Realization: A Technical Comparison of Four Core Anodizing Processes

The method used to color anodized aluminum parts directly impacts their durability, UV stability, and cost. For purchasers, selecting the right process is crucial for matching the product’s intended application and budget. There are four primary anodize types for coloring.

[Insert table comparing 4 types: Dip Dye, Electrolytic, Integral, Interference — with key parameters like color range, UV stability, cost, and ideal applications.]

2.1 Organic Dip Coloring

This is the most common method for achieving a wide spectrum of vibrant anodized colors, such as blue anodized aluminum or bright red. After anodizing, parts are immersed in a tank of organic dye, which is absorbed into the open pores of the oxide layer.

This process offers the greatest aesthetic flexibility, making it ideal for consumer electronics or branded components where specific hues are required. However, purchasers should note that the UV resistance of organic dyes varies. For indoor products, this is an excellent choice. For outdoor applications, specifying high-performance, lightfast dyes is essential to prevent fading.

2.2 Electrolytic Coloring (Two-Step Anodizing)

For applications demanding the highest durability, electrolytic coloring is the superior choice. This two-step process first creates a clear anodized layer, then immerses the part in a second bath containing inorganic metal salts (typically tin, cobalt, or nickel). An electric current deposits these metallic particles into the bottom of the pores.

The resulting color—ranging from champagne to a deep anodized aluminum bronze color and black—is created by light refraction off these stable metal particles. This makes the finish extremely resistant to UV degradation and ideal for architectural projects, automotive trim, and any component exposed to harsh environmental conditions.

2.3 Integral Coloring

Integral coloring combines the anodizing and coloring steps into a single process. It uses a specialized electrolyte that forms a colored oxide layer as it grows. The resulting finish is typically limited to bronze and black shades.

While this one-step process produces an exceptionally abrasion-resistant surface, it is generally more expensive and offers less color flexibility. It is specified for high-performance applications where extreme wear resistance is the primary concern.

2.4 Interference Coloring

This advanced technique creates color through optical interference. After anodizing, the pore structure is altered and metal is deposited to manipulate the way light waves interact, selectively canceling out certain wavelengths. The result is a visible color that arises not from dyes, but from how light reflects and refracts.

Interference coloring produces a palette of stable hues like blue, green, and grey. It is a premium choice for high-end architectural and design projects that require both uniqueness and longevity in appearance.

3.0 The Purchaser’s Guide to Color Consistency: A Systematic Approach

For any wholesale order, color consistency is the most critical factor. A lack of uniformity across a batch can lead to costly rejects and production delays. Achieving a consistent anodize color is a technical challenge, but it can be managed effectively through a systematic approach involving material specification, process control, and clear communication.

3.1 Quantifying Consistency: The Role of Delta E (ΔE)

Visual inspection is subjective. The industry standard for objectively measuring color variation is Delta E (ΔE), a metric that quantifies the perceived difference between two colors. A ΔE of 1.0 is the smallest difference the human eye can typically detect.

For architectural applications, the AAMA 611 standard allows for a ΔE of up to 5. However, for high-quality cosmetic parts, a much tighter tolerance of 1 to 3 ΔE is often required. Specifying an acceptable ΔE range in your quality control documents is the first step toward ensuring consistency.

3.2 Material Sourcing: The Most Critical Factor

[Insert checklist block: “What to Include in a Material Spec for Anodizing”]

The single greatest variable in anodizing color is the aluminum itself. Anodizing reveals the underlying metallurgy of the material; it does not hide it. Different alloys, and even different production lots of the same alloy, will react differently.

- Specify “Anodize Quality” (AQ) Alloys: For cosmetic applications, always specify AQ-grade alloys. 6063 is the standard for extrusions, and 5005 is the standard for anodized aluminum sheet metal. These alloys have a controlled chemical composition that results in a clearer, more uniform anodic layer, which is essential for consistent color absorption.

- Avoid High-Copper/Zinc Alloys for Light Colors: High-copper or high-zinc alloys, like 2024 and 7075, tend to darken significantly after anodizing due to their base composition. This makes them unsuitable for achieving light or vivid colors.

- Procure from a Single Lot: To minimize variation in large production runs, it is best practice to source all raw material from the same mill lot. This ensures the metallurgical composition is as consistent as possible across all parts.

3.3 Mitigating Common Production Issues: Welding

Welding can introduce significant color variation. The heat from welding creates a “heat-affected zone” (HAZ) that alters the metal’s structure, causing it to anodize to a different shade. This creates an undesirable “halo” effect that is visible in the finished part.

The choice of welding filler rod is also critical. Using a 4043 filler rod (high in silicon) will result in a dark grey or black weld line after anodizing. To ensure the best possible match, your fabrication drawings should explicitly specify the use of a 5356 filler rod, which is magnesium-based and anodizes to a color very similar to 6000-series alloys.

3.4 The YISHANG Commitment to Process Control

While material is the largest variable, precise control over the anodized process parameters is what ensures repeatability. At YISHANG, we utilize automated systems to meticulously manage variables like electrolyte concentration, temperature, current density, and immersion time. This commitment to process control allows us to deliver the most consistent finish possible for your anodized aluminum parts.

As a trusted anodized aluminum parts manufacturer, we support OEM and ODM clients with bulk anodized aluminum production, helping global sourcing teams maintain visual tolerance and industrial durability across every order.

4.0 Performance and Specifications: Choosing the Right Anodize Types

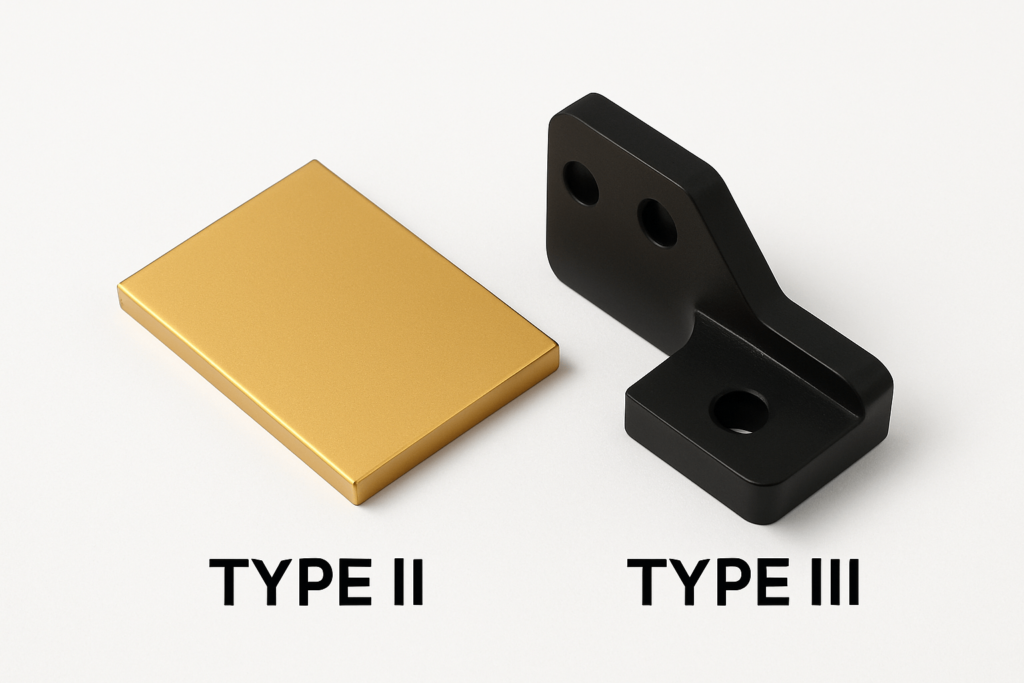

[Insert comparison table: Type II vs Type III — thickness, color options, wear resistance, indoor/outdoor suitability, specs referenced]

Selecting the correct anodizing specification is essential for ensuring a product’s long-term performance. The choice between the two most common types, Type II and Type III, is a critical decision based on the balance between aesthetics and durability.

4.1 Type II (Conventional Sulfuric Anodizing)

Governed by the military specification MIL-A-8625 Type II, this is the standard for most decorative and commercial applications. It produces a durable, corrosion-resistant oxide layer typically between 5 and 25 microns thick.

The key advantage of Type II is its porous structure, which is ideal for absorbing dyes. This makes it the best choice when a wide range of anodized colors for aluminum is required. It provides excellent performance for consumer electronics, architectural trim, and automotive components.

4.2 Type III (Hardcoat Anodizing)

MIL-A-8625 Type III, or “hardcoat” anodizing, is an engineered finish focused on maximum durability. The process uses lower temperatures and higher voltages to create a much thicker (over 25 microns) and denser oxide layer. This results in a surface that is exceptionally hard (often exceeding 60 Rockwell C) and highly resistant to abrasion and wear.

This enhanced performance, however, limits the color options. The dense layer and the process itself create a natural dark grey or bronze finish. While Type III can be dyed, the options are generally limited to black or other dark tones. It is the required specification for high-wear components in the aerospace, military, and industrial machinery sectors.

4.3 How to Specify Finishes on Technical Drawings

Clear specifications are essential for quality control. For architectural projects, reference AAMA 611, which defines Class I (0.7 mil minimum thickness) for exterior use and Class II (0.4 mil minimum) for interior use.

For most other applications, use the military specification. A complete callout includes the type and class (Class 1 for non-dyed, Class 2 for dyed). For example:

- “MIL-A-8625, Type II, Class 2, Black” specifies a standard anodize with black dye.

- “MIL-A-8625, Type III, Class 1” specifies an undyed hardcoat finish.

5.0 Beyond Color: How Texture Defines the Final Appearance

The final look of an anodized aluminium finish is a combination of color and surface texture. The anodizing process preserves the underlying texture of the metal, so all mechanical or chemical texturing must be performed before anodizing.

- Matte/Satin Finish: Achieved through chemical etching or bead blasting, this finish diffuses light for a soft, non-reflective appearance. It is excellent for high-touch surfaces as it helps to hide fingerprints and minor scuffs.

- Polished/Bright Finish: Mechanical buffing and chemical bright-dipping create a mirror-like surface before anodizing. The clear anodic layer then protects this high-gloss finish, making it ideal for decorative trim and luxury goods.

- Brushed Finish: A unidirectional grain is created by mechanically brushing the aluminum. This provides a modern, technical aesthetic popular in electronics and high-end appliances.

6.0 Future Innovations: What to Expect from Anodizing Technology

The technology behind anodizing continues to evolve, driven by demands for greater sustainability and performance. As a forward-thinking partner, YISHANG stays at the forefront of these innovations.

Key trends include the development of eco-friendly, heavy-metal-free dyes and nickel-free sealing processes that reduce environmental impact. Additionally, nanotechnology is being integrated to create nano-structured films with superior mechanical properties and unique optical effects. In the future, expect to see smart coatings with self-healing properties and digital dyeing techniques that allow for intricate, permanent patterns to be embedded directly into the anodized coating.

7.0 Professional FAQ: Answering Key Procurement Questions

Can you anodize steel or stainless steel? No. The anodizing process is specific to non-ferrous metals like aluminum, titanium, and magnesium. Attempting to anodize steel or anodize stainless steel in a standard aluminum anodizing bath would result in the parts being dissolved by the acid electrolyte.

How does anodizing affect dimensional tolerances? Anodizing does change part dimensions. The oxide layer grows both into and out of the substrate. For Type II, the growth is approximately 33% of the total film thickness. For Type III hardcoat, it is closer to 50%. This must be accounted for in the initial part design, especially for components with tight tolerances.

What is the UV stability of different anodized colors? Colors from electrolytic coloring (bronze, black) are extremely UV stable and will not fade. Colors from organic dyes have varying lightfastness ratings. For outdoor applications, it is crucial to specify a dye with a high rating (8 or higher on a 1–10 scale) to ensure long-term color stability. A quality sealing process is also essential to lock in the color and prevent fading.

Is an exact Pantone or RAL color match possible? Achieving an exact match to a paint color code is generally not feasible with anodizing. Due to the variables of alloy and the translucent nature of the finish, the industry standard is to work with an approved anodized aluminum color chart or physical range samples that define the acceptable light and dark limits for a specific color.

Can a part be re-anodized a different color? Yes, but it requires chemically stripping the original anodized layer first. This process removes a small amount of the base metal, which may affect dimensions. After stripping, the part can be re-processed and dyed a new color.

At YISHANG, we are committed to providing not just high-quality metal products, but also the expertise to ensure your project’s success from start to finish.

🔍 For detailed technical support, OEM anodizing consultation, or access to our custom anodized aluminum specification sheet, contact us today and speak with a dedicated sourcing advisor.