Introduction: Why Magnesium Density Matters in B2B Sourcing

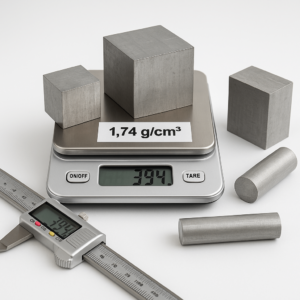

For procurement professionals and technical buyers, magnesium’s density is not just a figure—it’s a critical parameter that influences logistics cost, part performance, and material forecasting. As the lightest structural metal (1.738 g/cm³ at 20°C), magnesium is a strategic material in lightweighting, high-throughput production, and volume-based shipping scenarios.

This guide delivers a practical and technical perspective for industrial buyers, engineers, and specifiers dealing with magnesium-based components. With an emphasis on procurement accuracy, RFQ language, and design-to-delivery consistency, the goal is to help you make better decisions at scale.

Magnesium Density and Standard Conversions

Reference Densities in Global Units

- 1.738 g/cm³ (standard value at 20°C)

- 1738 kg/m³ (metric)

- 0.063 lb/in³ (imperial)

- 1.0047 oz/in³ (aerospace weight spec)

These values offer conversion-ready references. For example, a 10x10x10 cm magnesium block weighs just 1.738 kg—ideal for parts where reduced shipping weight or lower rotational mass matters.

What Causes Real-World Variations

In reality, measured part density differs from theoretical values due to:

- Casting porosity or gas pockets

- Surface treatments or powder coatings

- Microstructural inconsistencies

For example, AZ91 die-cast housings often show measured densities between 1.80–1.82 g/cm³, especially in thin-wall components. Understanding this helps avoid confusion when validating supplier reports.

Why Magnesium Is So Light — And What That Means in Practice

Atomic Structure and Specific Volume

Magnesium has a low atomic weight (24.3 u) and a hexagonal close-packed (HCP) structure. This limits how tightly atoms can pack together compared to FCC metals like aluminum. As a result, magnesium has fewer atoms per unit volume and is naturally less dense.

Relevance for Industrial Buyers

- Optimize freight cost per unit

- Improve weight-to-strength ratio in products

- Achieve faster response time in moving parts and rotating assemblies

The density advantage becomes commercially significant in markets like electric vehicles, medical robotics, and aerospace paneling, where every gram saved can mean added performance or cost reduction.

Manufacturing Influence on Final Density

Processing Methods and Density Outcomes

| Process | Density Outcome | Use Case |

|---|---|---|

| Die Casting | Moderate (porosity risk) | High-volume casings, brackets |

| Extrusion | High (low porosity) | Load-bearing rails, arms |

| Forging | Very High | Impact-prone structures |

| Sintering | Lower density | Small intricate designs |

Density variability stems from cooling rates, trapped gases, and thermal gradients—all of which influence microstructure integrity.

Specifying Density Requirements to Suppliers

To tighten tolerances in high-performance parts:

- Define alloy + process (e.g., AZ31 forged)

- Indicate required density range (e.g., 1.77 ± 0.01 g/cm³)

- Clarify inclusions (e.g., inserts, anodized layers)

YISHANG supports density test certification, including Archimedes testing and micro-CT scans, on request.

Magnesium Alloy Density Comparison Table

Density Chart by Alloy and Application

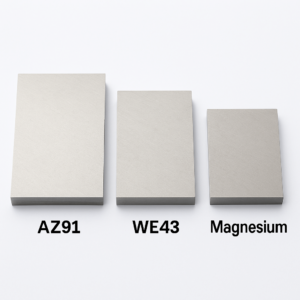

| Alloy | Density (g/cm³) | Key Alloying Elements | Applications |

|---|---|---|---|

| AZ91 | 1.81 | Al 9%, Zn | Gear housings, engine brackets |

| AZ31 | 1.77 | Al 3%, Zn | Aerospace panels, laptop chassis |

| ZK60 | 1.83 | Zn, Zr | Forged frames, racing components |

| WE43 | 1.85 | Y, Rare Earths | Biomedical implants, satellites |

📌 Tip: Consider magnesium alloy alternatives based on strength-to-density ratio and corrosion behavior—not just density alone.

Visual Density Distribution (Optional Chart Area)

Add a bar chart or gradient scale showcasing alloy density variations, aiding visual learners and quick engineering reviews.

Density in Design: What Engineers and Buyers Must Align On

Balancing Weight Reduction and Part Performance

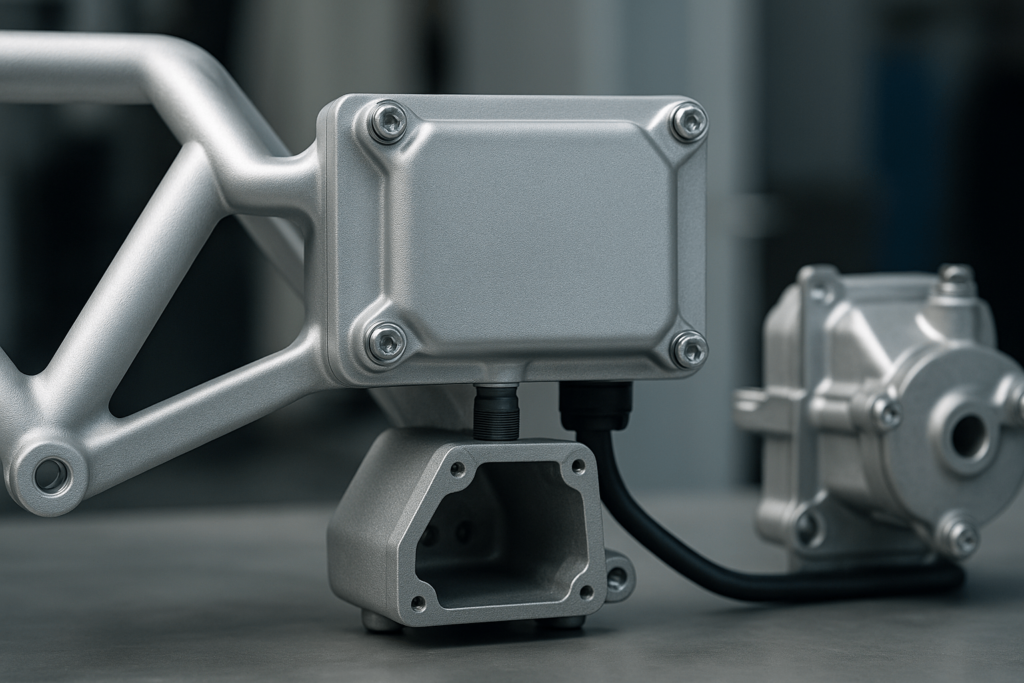

Optimizing for weight doesn’t mean compromising performance. In structural parts:

- Thicker ribs or wall support may offset lower density

- Vibration damping varies between alloys

- Coating compatibility can alter net material volume

A lightweight shell may require reinforced design to handle thermal cycles or torque loads—critical in powertrain components or aerospace enclosures.

Design-to-RFQ Translation for Accurate Quoting

- Include CAD-weight tolerances based on target alloy

- Note load-bearing vs. non-load regions in BOM

- Specify machining allowances or secondary operations that may remove material

These details reduce quoting errors, avoid rework, and ensure cost-to-performance optimization.

Specifying Density in Documentation and RFQs

3-Step Density Declaration Checklist

- Alloy + process name (e.g., ZK60 extruded)

- Density range and tolerance (e.g., 1.83 ± 0.01 g/cm³)

- Inspection type (e.g., CT scan or immersion test)

Density Verification Techniques

| Method | Accuracy | Ideal For |

|---|---|---|

| Archimedes Method | ±1% | General mechanical parts |

| X-ray CT Scan | ±0.5% | Aerospace, defense, implants |

| Helium Pycnometry | ±0.3% | R&D, powder-based materials |

Specifying your preferred method improves supplier alignment. YISHANG offers all three for qualified orders.

Buyer-Focused FAQs: Magnesium Density Explained

Is magnesium always lighter than aluminum?

Yes—by ~33% in volume terms. Magnesium’s density advantage can yield significant benefits in drone arms, EV brackets, and satellite frames.

Why does my part weigh more than specified?

Often due to:

- Trapped gases or shrinkage cavities

- Coatings not deducted from raw weight

- Alloy contamination

Can I request density tests?

Yes. Just specify your method (e.g., Archimedes or CT scan) in the RFQ. YISHANG regularly provides density compliance reports.

What’s a practical density tolerance?

- ±0.01 g/cm³ for machined or structural parts

- ±0.02 g/cm³ for die-cast or decorative elements

How do I calculate magnesium part weight?

Use: Volume × Alloy Density

For example, a 500 cm³ part using AZ31 (1.77 g/cm³):

500 × 1.77 = 885g

Final Thoughts: Density as a Strategic Metric in Sourcing

Density is more than a specification—it impacts:

- Material forecasting accuracy

- Supply chain efficiency

- Regulatory weight limits in transit

- Final part yield and machining cost

For B2B buyers sourcing structural components, understanding magnesium density enables more predictable project outcomes and better margin control.

YISHANG helps procurement teams align on technical specs, minimize weight deviation, and deliver on quality requirements—whether for industrial casings or aerospace enclosures.

💬 Have density-specific requirements? Contact YISHANG to discuss alloy options and inspection standards for your next production run.