Introduction: The Critical Component in Structural Integrity

In the world of infrastructure, from telecommunications to energy transmission, the stability of vertical structures is non-negotiable. While the towering masts and poles are most visible, their integrity often relies on a network of high-tensile steel cables.

These are guy wires, critical engineering components that anchor tall structures, ensuring their stability against immense environmental forces.

For procurement managers and project engineers, selecting the right guy wire system is a decision with significant implications for safety, longevity, and total project cost. This guide provides the essential technical knowledge required to navigate specifications, understand material performance, and ensure compliance with industry standards. YISHANG, as a global supplier with over 26 years of metal fabrication expertise, supports every stage of this process with tailored, export-ready solutions for wholesale engineering and infrastructure clients.

To better understand how all these elements work together, let’s begin with the fundamentals.

Chapter 1: Foundational Principles: The Role of a Guy Wire System

🧱 Foundations Without Concrete: Why Guy Wires Are Essential

A guy wire stabilizes a freestanding structure by converting lateral forces, such as wind load, into manageable tension transferred to ground anchors.

Engineering Efficiency: The ‘Virtual Foundation’

A self-supporting tower requires a massive base and heavy framework to resist bending forces—a costly approach in both materials and construction. Conversely, a guyed mast works primarily in compression. The guy wires create a wide “virtual foundation,” allowing the mast to remain slender and lightweight. This makes guyed structures the most cost-effective solution for achieving height, especially in large-scale telecom or energy projects.

📌 Use Case Tip: Guyed towers are widely used in rural or coastal zones where ground space is available and where self-supporting towers would dramatically increase cost.

Chapter 2: The Engineer’s Perspective: The Science of Stability and Strength

📐 Force, Angle, and Safety: Behind Every Wire Is a Physics Problem

Procurement decisions for guy wire systems hinge on applied physics. Understanding the engineering behind these systems is crucial for ensuring both safety and cost-effectiveness.

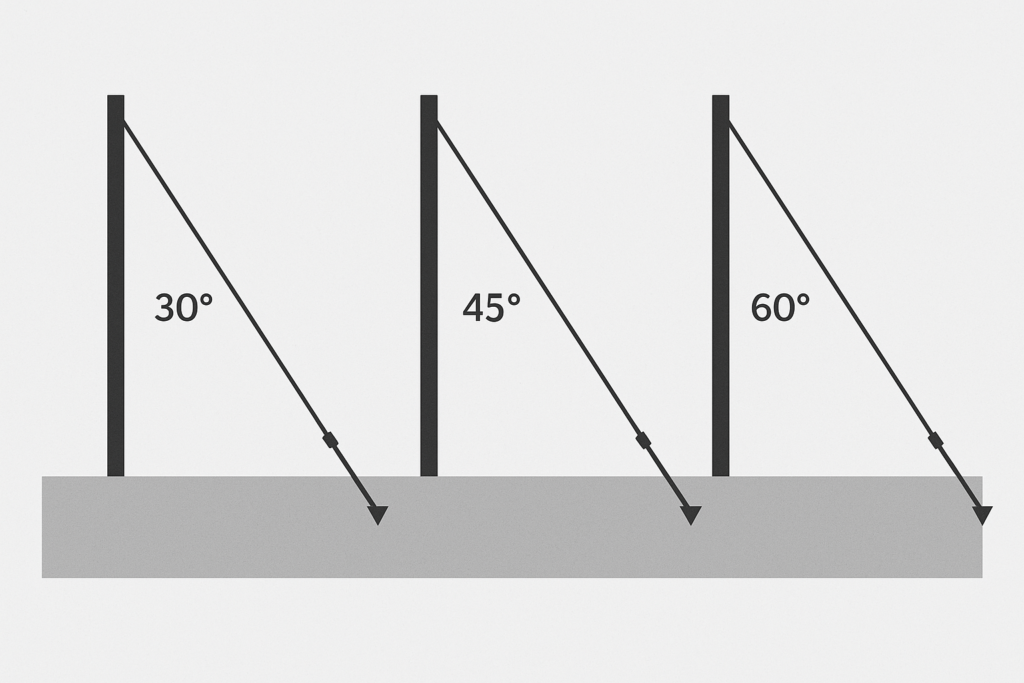

The Critical Importance of Angles

Installation angle directly affects guy wire tension. A shallow angle increases required tension exponentially. In contrast, steeper angles (typically 30°–60°) balance force distribution and anchoring footprint. For example, a 30° angle may require double the tension of a 60° angle to resist the same horizontal load.

📎 Engineer’s Note: In high-wind zones, steeper angles reduce anchor stress and increase reliability.

System Anatomy: Components and Their Specifications

🧩 Know Your Parts: The Complete Guy Wire Kit

- Guy Strand: Core tension member, usually 1×7 or 1×19 steel wire.

- Anchor System: Transfers tension forces to soil. Choice depends on geotechnical reports.

- Hardware Assembly: Includes turnbuckles (tension adjustment), thimbles (loop protection), and clamps (wire termination).

- Insulators: Used to prevent electrical conduction, especially in utility or RF-sensitive environments.

Designing for Compliance: Understanding the TIA-222 Standard

📄 Regulation Spotlight: TIA-222 and How to Apply It

TIA-222 is the North American standard for telecom structures. It classifies structures (Class I–III) based on risk and defines exposure categories (B–D) depending on terrain. Each classification determines load requirements, making it vital for project compliance.

Chapter 3: Material Specification: A Critical Procurement Decision

🔍 Choose Wisely: Materials Determine Life Cycle and Risk

Material selection impacts durability, maintenance, and project cost.

The Industry Standard: Galvanized Steel

Most guy wires use galvanized steel due to its excellent strength-to-cost ratio. Coating classes (ASTM A475) include:

- Class A: Mild environments

- Class B: Moderate conditions

- Class C: Harsh or corrosive zones

✅ Long-tail keyword: guy wire specifications PDF

For Harsh Environments: Stainless Steel

Stainless steel is preferred in coastal or chemical-heavy zones. However, all components must match to avoid galvanic corrosion—never mix stainless wires with galvanized clamps.

Specialized Applications: Synthetic Composites

Fiberglass or aramid fiber (Kevlar®) offers RF transparency and corrosion immunity but needs UV protection.

📌 Procurement Tip: Coastal projects typically specify 316 stainless steel hardware throughout the system.

| Material | Strength-to-Cost | Corrosion Resistance | Key Consideration |

|---|---|---|---|

| Galvanized Steel | Excellent | Good | Specify Class A–C per environmental severity |

| Stainless Steel | Moderate | Excellent | Must use matched components to prevent corrosion |

| Synthetics (Kevlar) | High | Immune | For RF-transparent or dielectric applications |

Chapter 4: Installation Integrity: Tensioning and Safety Protocols

🛠️ Precision in Execution: Installation Is Engineering Too

Proper installation ensures design performance. Global procurement teams should coordinate with installers to verify calibration and anchoring procedures.

The “10% Rule” for Optimal Tension

Industry practice suggests pre-tensioning to 10% of the wire’s breaking load. For example, 665 lbs for a 1/4″ EHS wire (rated at 6,650 lbs). Under-tensioning causes slack and vibration; over-tensioning risks mast collapse.

✅ Long-tail keyword: guy wire installation procedure

Safety Compliance: Mitigating Electrical Hazards

⚡ Electrical Safety Matters: The Insulator’s Role

OSHA requires insulators at least 8 ft (2.44 m) above ground on guy wires near power lines. These prevent accidental energization. Additional safeguards may include polymer coatings and grounded cable ends.

Chapter 5: Lifecycle Management: Maintenance and Inspection

🔧 Protecting the Investment: Plan for Longevity

Routine maintenance extends guy wire life and reduces failure risk. YISHANG provides post-installation services including inspections, re-tensioning, and corrosion treatment.

Combating Vibration: The Role of Dampers

Stockbridge dampers dissipate Aeolian vibration and prevent galloping, which can lead to fatigue cracks or anchor failure.

📎 Engineer’s Note: Dampers should be installed at calculated distances from endpoints for maximum efficiency.

Inspection Protocols and Replacement Criteria

Inspections are recommended every 3–5 years. Focus on corrosion, wire diameter, tension, and hardware integrity. Replace wires with frayed strands or visible diameter loss.

✅ Long-tail keywords: guy wire maintenance checklist, how to prevent guy wire corrosion

Chapter 6: The Future of Guyed Structures: Technology and Innovation

📡 Smart Systems and Stronger Materials: What’s Next?

CFCC (carbon fiber composite cables) offers high strength-to-weight with zero corrosion. SHM (Structural Health Monitoring) using fiber-optic sensors enables real-time data collection for predictive maintenance.

YISHANG is investing in SHM-ready assemblies to meet next-gen infrastructure demands.

Conclusion: A Partnership in Structural Excellence

Selecting the right guy wire system demands both engineering insight and supply chain precision. YISHANG provides technical support, OEM service, and global logistics for custom solutions.

📩 Need engineered guy wire kits for global deployment? Contact YISHANG today for drawings, pre-assembly, or compliance documentation.

Frequently Asked Questions (FAQs)

- What angle is best for guy wires? 30°–60°, with 45° typically ideal.

- How often should guy wires be inspected? Every 3–5 years, more often in corrosive environments.

- What are the ceramic “balls” on some wires? Strain insulators for electrical safety.

- What’s the difference between guyed vs self-supporting towers? Guyed uses external wires; self-supporting is heavier and standalone.

- How is guy wire tension measured? Using dynamometers or sonic vibration timing methods.

- What causes guy wire galloping? Ice build-up or aerodynamic imbalance in strong wind.