In industrial metal fabrication, where precision defines quality and efficiency dictates profitability, the initial cut is a critical control point in the entire manufacturing process. While advanced systems like laser cutting have their place, the industrial bandsaw remains the foundational workhorse for preparing raw stock.

For procurement managers and engineers evaluating supply chain partners, understanding a fabricator’s mastery of this core process is essential. It offers insight into their commitment to quality, operational consistency, and ultimately, their ability to deliver reliable, cost-effective components at scale.

This guide moves beyond basic operation to explore the science and strategy behind professional metal bandsaw cutting, offering a transparent look into the processes that ensure quality from the very first step. If you’re also sourcing CNC machining or looking for high-volume metal cutting in China, check out our related guides on precision CNC metalworking.

Part 1: The Bandsaw’s Critical Role in Modern Metal Fabrication

The bandsaw’s ongoing relevance stems from its unmatched blend of versatility, cutting power, and cost-efficiency. It’s not merely a cutting tool—it serves as a production cornerstone for metal fabrication facilities worldwide.

More Than a Saw: The Bandsaw as a Primary Manufacturing Tool

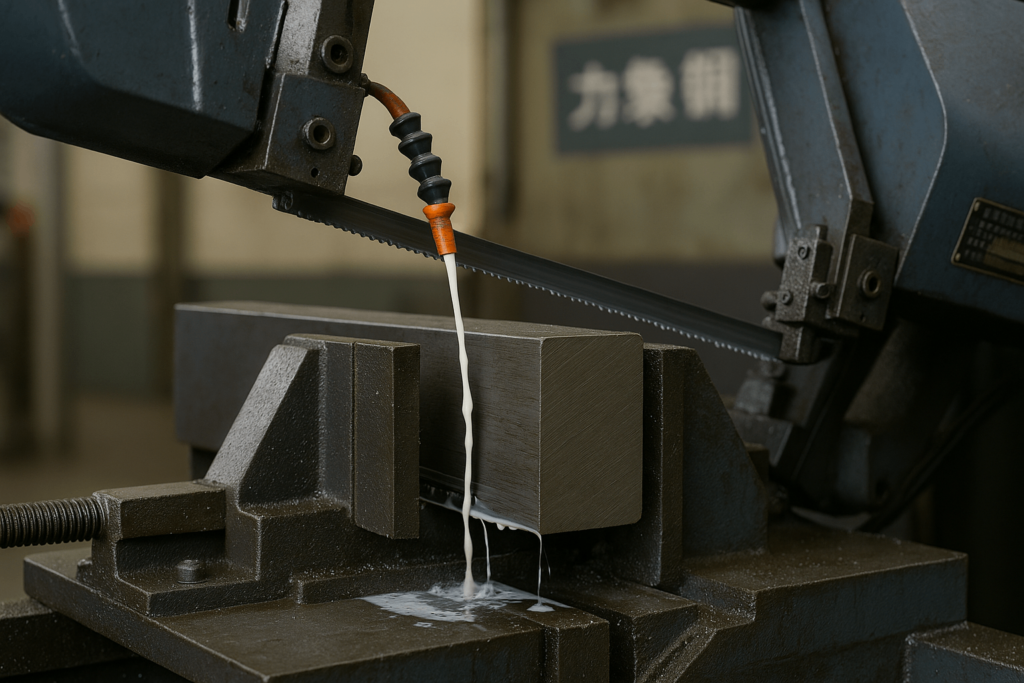

The primary role of the industrial bandsaw is to execute initial precision cuts that ready materials for downstream processes. It’s commonly used for cutting structural steel, solid bar stock, and tubing to precise lengths for machining.

Accurate first cuts improve efficiency throughout the production chain. A clean, square cut from a properly calibrated saw minimizes waste and reduces secondary processing time, preventing tolerance stacking that can compromise final components.

A Brief History: From a Stalled Idea to an Industrial Powerhouse

The evolution of the bandsaw illustrates how metallurgical innovation drives machine reliability. Though first patented in 1809, the design remained unworkable due to limitations in blade metallurgy.

It wasn’t until 1846 that Anne Paulin Crepin developed a welding technique to produce a durable, flexible blade—transforming the bandsaw into an essential industrial asset.

Choosing the Right Machine: Horizontal vs. Vertical Bandsaws

In professional shops, bandsaws are classified by blade orientation. Choosing between horizontal and vertical formats optimizes the workflow and matches the tool to the task.

Horizontal bandsaws are ideal for precision cut-offs in long stock like beams or tubing. Vertical models, often used for contour cutting, are well-suited to tool and die fabrication or custom-shaped components.

If you’re looking for a cost-effective alternative to laser cutting for solid or bundled stock, horizontal bandsawing remains a top choice.

Part 2: The Science of the Metal Cut: Machine Anatomy & Blade Selection

Achieving an accurate, clean cut requires more than sharp blades. It involves understanding the machine’s structure and choosing the correct cutting parameters and blade configuration. This is crucial in any custom steel cutting service in China focused on minimizing cost-per-cut while maintaining tight tolerances.

Anatomy of an Industrial Bandsaw: A System Built for Rigidity

Professional-grade bandsaws are built on rigid frames—usually of welded steel or cast iron—to withstand the continuous force of a tensioned blade without flexing.

Rigidity is achieved through the Stability Triad:

- Blade Tension: Adds beam strength to maintain a straight line.

- Tracking System: Keeps the blade centered using crowned wheels.

- Guides: Prevent blade twist by providing lateral and vertical support.

The Blade is Your Business: A Professional’s Guide to Metal-Cutting Blades

Blade selection influences productivity, part quality, and total cutting cost. Procurement teams evaluating suppliers can gain insight into capability by reviewing blade strategy.

Blade Material and the Economics of Production:

- Bi-Metal Blades: Feature a hardened HSS edge and flexible steel backer. Widely used for carbon steel, aluminum, and general-purpose cutting.

- Carbide-Tipped Blades: Withstand heat and wear for stainless, hardened steel, and exotic alloys. Ideal for high-volume or automated lines.

Tooth Geometry Matters:

Tooth pitch (TPI) must match material thickness. Hook-style teeth are aggressive and effective for soft metals like aluminum, while variable pitch reduces vibration in profiles.

Blade Selection Chart for Metals:

| Metal Type | Recommended Blade | TPI Range | Key Considerations |

|---|---|---|---|

| Mild Steel (Solid) | Bi-Metal | 10–18 | Reliable for general-purpose cuts. |

| Structural Steel | Bi-Metal (Variable Pitch) | Variable | Minimizes vibration on profiles. |

| Stainless/Tool Steel | Carbide-Tipped | 14–24 | Extended life offsets initial cost. |

| Aluminum/Brass | Bi-Metal (Hook Tooth) | 6–10 | Fast cutting with smooth finish. |

Looking for a bandsaw blade troubleshooting guide? See Part 6 for maintenance best practices and issue diagnosis.

Part 3: The Precision Setup Protocol: Tuning for a Perfect Metal Cut

Consistent performance begins with proper setup. Shops like YISHANG implement standard protocols to ensure every shift delivers repeatable results. These are especially critical in custom fabrication workflows with high repeatability standards.

5-Step Setup SOP for Bandsaw Precision

- Blade Tracking: Ensure blade runs true on the wheels.

- Tensioning: Use the flutter test to confirm optimal tightness.

- Guide Alignment: Adjust roller or carbide guides to minimize flex.

- Vise Squaring: Verify with machinist’s square for 90° accuracy.

- Coolant Check: Ensure adequate flow and proper coolant ratio.

Part 4: Mastering Industrial Cutting Techniques

Operator skill adds value by optimizing machine settings for different materials. For high-volume metal saw cutting applications, this can significantly reduce downtime and tool wear.

- For solid bar vs. structural profiles, feed rate and pressure must adjust dynamically.

- In bundle cutting, tight clamping ensures squareness and safety when processing multiple bars simultaneously.

- Monitoring chip formation helps fine-tune parameters. Silver chips indicate efficient cutting; blue or burnt chips signal excessive heat or dull blades.

Part 5: The Fabricator’s Choice: Bandsaw vs. Alternative Cutting Methods

Understanding a shop’s choice of cutting methods reveals their cost and quality priorities.

- Bandsaw vs. Abrasive Saw: Abrasive saws produce HAZ and excessive heat. Bandsaws avoid thermal stress.

- Bandsaw vs. Cold Saw: Cold saws offer finer finishes but are less versatile and costlier to operate.

- Bandsaw vs. Laser/Plasma: Lasers excel in thin sheet cutting. Bandsaws outperform on solids and bundles.

Looking to compare all cutting methods in detail? See our deep-dive guide on metal cutting process selection.

Part 6: Pro-Level Maintenance & Troubleshooting for Metal Saws

Proactive maintenance ensures uninterrupted production and part quality.

Routine Maintenance Schedule

- Daily: Clean chips; inspect coolant flow.

- Weekly: Check blade brushes and guides.

- Monthly: Flush coolant tank; test hydraulic pressure.

Common Issues & Corrective Actions

| Problem | Likely Cause(s) | Recommended Fix |

|---|---|---|

| Crooked Cuts | Low tension, worn guides | Retension blade; replace guides |

| Premature Blade Wear | Incorrect feed/speed settings | Tune RPM and feed rate; monitor coolant |

| Burnt Chips | Overheating from low feed rate | Increase feed or coolant flow |

| Stripped Teeth | Wrong TPI or sudden entry | Use appropriate TPI; reduce entry pressure |

Part 7: The Future of Metal Sawing: Automation & Industry 4.0

At YISHANG, bandsawing aligns with smart factory principles.

- CNC Bandsaws: Enable programmed operations and consistent tolerances.

- Robotic Cells: Allow lights-out production and reduced labor dependency.

- Sensor Feedback: Predicts blade wear before failure, minimizing downtime.

If you’re seeking a smart manufacturing-ready metal cutting partner in China, our Industry 4.0-enabled workflow may be what you’re looking for.

Part 8: Safety First: OSHA-Informed Protocols for the Metal Shop

Compliance with safety standards enhances buyer confidence. YISHANG integrates OSHA-informed procedures in daily operations.

- PPE Use: ANSI Z87.1 eyewear; no gloves near blades.

- Lockout/Tagout: Mandatory for service or blade changes.

- Safe Handling: Secure workpieces fully before cutting; wait for full stop before removal.

From foundational cuts to fully automated cells, bandsaw cutting remains vital to precision metal fabrication.

Looking for an OEM metal-cutting partner in China? Contact YISHANG to request a quote or technical consultation on your next project involving high-precision, cost-effective industrial bandsaw cutting.