Introduction: Beyond the Skeleton Frame – Understanding the Language of Steel

The iconic steel frame is the backbone of modern construction. Yet for procurement managers and project leaders, it represents more than just structural integrity. It’s a dynamic system where material selection, engineering precision, and fabrication quality directly shape the success of commercial and industrial projects—from budget control to lifecycle performance.

This guide goes deeper than simple definitions. It explores the core engineering principles, essential components, and fabrication best practices that define high-performance steel structures. Our goal is to provide the insights needed to make informed procurement decisions and collaborate with a supplier that speaks the language of structural reliability and long-term value. Whether you’re sourcing custom steel fabrication services, industrial steel structure components, or galvanized steel frame systems in bulk, this guide is tailored to your buying perspective.

Section 1: The Material – Why Modern Construction Is Built on Steel

Every steel structure starts with its raw material. Understanding steel’s engineered characteristics is essential for evaluating why it’s the preferred option across industries, especially for buyers sourcing durable, high-volume metal components for global projects.

The Four Pillars of Performance: What Makes Steel “Structural”?

Structural steel isn’t just any steel—it’s engineered for performance. As defined by ASTM and other global standards, structural steel features specific chemical and mechanical properties designed to meet rigorous construction demands.

First, its strength-to-weight ratio is unmatched. A grade like ASTM A36 offers yield strength up to 250 MPa, supporting immense loads with leaner, lighter sections. For B2B buyers, this translates into lower transport costs, reduced structural dead loads, and minimized foundation work—key benefits when buying structural steel in bulk.

Next is ductility, the capacity to flex under stress without fracturing. In regions prone to seismic activity, ductile steel frames perform safely under lateral loading, a crucial feature for structural resilience.

Then comes stiffness—steel’s resistance to deformation. With a stable Young’s Modulus around 200 GPa, it enables engineers to predict deflection reliably and meet serviceability standards.

Finally, all these traits stem from a precisely controlled chemical composition—with carbon for hardness, manganese for strength, and low impurities to ensure consistency. For procurement teams, this means confidence in sourcing OEM structural components that perform as specified across batches and suppliers.

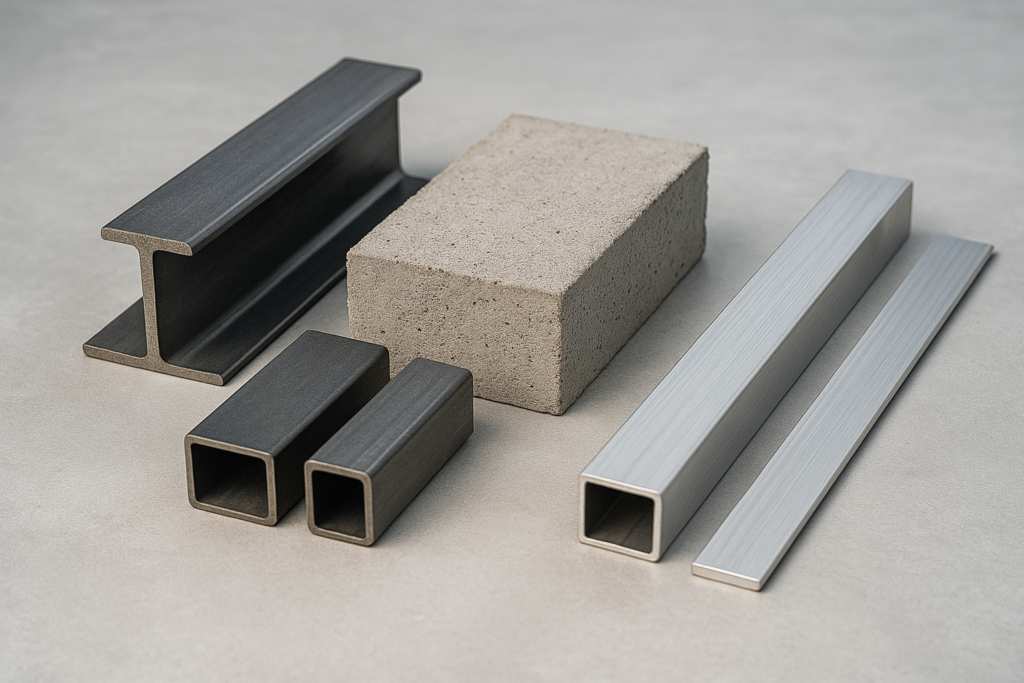

Steel vs. The Alternatives: A Clear-Cut Comparison

When evaluating materials for frames, enclosures, or modular structures, buyers often compare steel, concrete, and aluminum. Each offers trade-offs, but structural steel dominates where speed, span, and strength are essential.

Against concrete, steel’s advantage is speed. Steel structures are often fully fabricated offsite and assembled rapidly onsite—ideal for tight timelines. Steel’s lightweight sections also enable expansive open areas without intermediate columns, a major plus for warehouse and retail construction.

Compared with aluminum, steel offers far higher stiffness and load capacity, albeit with more weight. Aluminum’s high cost and limited structural roles mean it’s typically reserved for cladding or light architectural uses.

| Property | Structural Steel (A36) | Reinforced Concrete | Aluminum Alloy (6061-T6) |

|---|---|---|---|

| Tensile Strength | High (~400–550 MPa) | Low (~2–5 MPa) | Moderate (~310 MPa) |

| Density | High (~7,850 kg/m³) | Very High (~2,400 kg/m³) | Low (~2,700 kg/m³) |

| Stiffness (Young’s Modulus) | Very High (~200 GPa) | Moderate (~30 GPa) | Low (~69 GPa) |

| Strength-to-Weight Ratio | High | Low | Very High |

| Corrosion Resistance | Moderate (needs coating) | Good (steel embedded) | Excellent (self-passivating) |

| Fire Resistance | Moderate (requires protection) | Excellent | Poor (melts at low temperature) |

Section 2: The Anatomy of a Steel Structure – Its Core Components

Steel structures are modular systems, where each component plays a precise role. Wholesale buyers benefit from understanding the hierarchy and function of these core elements to better specify their needs in custom fabrication projects.

The Vertical Framework: Columns

Columns carry compressive loads from the superstructure down to the foundations. Their shape and strength determine load capacity and resistance to buckling.

Common types include:

- W-Shapes (I-Beams/H-Beams): Efficient under vertical and lateral loads.

- Hollow Structural Sections (HSS): Excellent torsional resistance and aesthetic appeal.

- Built-Up Box Columns: Custom-welded for high-rises and heavily loaded applications.

The Horizontal System: Beams and Girders

Beams transfer vertical loads laterally across floors and roofs. In a typical load path, smaller secondary beams (joists) support surfaces and transfer weight to primary beams (girders), which in turn deliver loads to columns. This layered logic ensures efficient force distribution and flexibility in spatial design.

The Stability System: Trusses and Bracing

Steel trusses enable long-span applications using minimal material, thanks to triangular geometry that distributes stress efficiently.

Bracing systems—diagonal members in walls and frames—resist lateral loads from wind and seismic activity. Effective bracing is key to preserving the building’s shape and structural integrity, especially in high-wind regions or multistory builds. An optimized steel frame bracing system can be the deciding factor for buyers evaluating structural reliability.

Section 3: The Design Philosophy – The Engineering Rulebook

Sound engineering governs every structural system. For wholesale procurement, suppliers must demonstrate adherence to design codes that protect against failure and ensure efficiency.

The Engineer’s Triad: Strength, Stiffness, and Stability

A structural component must:

- Withstand loading (strength)

- Control deflection (stiffness)

- Avoid shape failure (stability)

These traits interdepend. A member that’s strong but unstable can still fail via buckling. Design professionals aim for balance—an optimized structure meets all three without overdesigning any one factor. For procurement teams evaluating structural steel engineering for factories or commercial facilities, understanding this balance is crucial.

Why Stability Is More Than Just Strength

Buckling—especially Lateral Torsional Buckling (LTB)—is a real risk for slender members. LTB occurs when compression flanges twist and bend under bending loads.

Stability isn’t solved by thicker steel alone. It’s achieved through careful bracing, connection detail, and shape optimization. Reliable fabricators engineer these solutions in during production to ensure structural safety and efficiency.

Bolted vs. Welded Joints – What Procurement Needs to Know

- Bolted connections: Fast, cost-efficient, suitable for modular construction. Easy to inspect and replace.

- Welded connections: Continuous and strong. Better aesthetics and rigidity but costlier in labor and QA.

Each has merit. For field-assembled structures, bolts dominate. For shop-fabricated elements, welding delivers strength and simplicity. An experienced OEM metal structure supplier will recommend the right joining method for your application.

Safety Margins: ASD vs. LRFD Design Methods

Steel structures are designed using:

- ASD (Allowable Stress Design): Applies a fixed factor of safety.

- LRFD (Load and Resistance Factor Design): Applies reliability-based factors to loads and resistances.

LRFD is now standard in many regions. Choosing suppliers who understand both methods ensures cross-border compliance and alignment with international project codes.

Section 4: From Blueprint to Reality – Manufacturing, Finishing, and Performance

For buyers, steel fabrication is where structural theory becomes tangible. Suppliers must deliver not just product, but precision.

Digital Fabrication: CNC and Prefabrication in Modern Steel Manufacturing

Modern workshops use CNC systems to guide cutting, bending, and hole placement—ensuring sub-millimeter accuracy. That translates into:

- Fewer rework delays

- Faster site installation

- Predictable part integration

Laser and plasma cutting create clean profiles, minimizing heat distortion. Prefabrication brings components together in-house, under strict QA, before shipment—ideal for global delivery. If you’re sourcing prefabricated steel for B2B projects, this digital fabrication capability reduces risk and increases consistency.

Surface Treatment: Guarding Against Corrosion

Unprotected steel is vulnerable to corrosion, especially in outdoor or humid environments. The most effective treatments include:

- Hot-Dip Galvanizing (HDG): ASTM A123-compliant, it bonds molten zinc to steel.

- Three-coat paint systems: Zinc-rich primer + epoxy coat + UV-resistant topcoat.

Choosing the right finish depends on application. A good supplier will guide the spec to match site conditions and service life goals. This is particularly vital when purchasing galvanized steel frame components for long-term infrastructure use.

Sustainability and Recyclability – Steel’s Green Value

Steel’s recyclability positions it as a material of the future:

- Over 90% of structural steel comes from recycled sources

- Electric Arc Furnaces (EAFs) reduce emissions

- Qualifies for LEED credits in sustainable construction

Buyers aligned with green goals can highlight steel’s lifecycle value in public and institutional bids. Partnering with an industrial steel structure supplier who supports documentation and compliance helps unlock these sustainability certifications.

Conclusion: Steel – Built for Strength, Delivered with Precision

Steel structures are more than beams and bolts. They are precision systems shaped by material science, validated by engineering, and delivered by capable fabricators.

For procurement professionals, the right partner ensures:

- Material compliance with ASTM, ISO, and AISC

- Accurate, code-ready components

- Custom fabrication to industrial-grade tolerances

- Scalable, high-volume manufacturing for global sourcing

YISHANG delivers all of the above. With 26+ years of experience, ISO 9001 and RoHS compliance, and export to 50+ countries, we are a trusted supplier of OEM/ODM steel fabrication. Contact us today for a fast quote or to request a drawing review—we’ll respond within 24 hours.

Frequently Asked Questions (FAQ)

Q: What is the main difference between a beam and a girder?

A: Beams support floor or roof panels and transfer loads to girders. Girders are larger primary members connecting to columns.

Q: Why is bracing important in steel structures?

A: Bracing stabilizes the structure against wind and seismic forces. It prevents sway and collapse under lateral stress.

Q: Can steel structures be modified later?

A: Yes. Especially with bolted frames, parts can be removed or replaced for future upgrades.

Q: Is welding stronger than bolting?

A: Welds are seamless and strong but require skilled labor. Bolts are faster to install and easier to replace.

Q: How does steel handle fire?

A: Steel doesn’t burn, but it weakens under extreme heat. Fireproof coatings or enclosures are typically applied.

Q: What does strength-to-weight ratio mean in practice?

A: It means using less material to achieve structural strength—saving weight, cost, and enabling longer spans.

Q: What is your typical lead time for custom steel fabrication orders?

A: Lead times vary by complexity and quantity, but most standard orders ship within 15–25 working days.

Q: Do you offer support for structural design or component engineering?

A: Yes, we provide design assistance and engineering consultation based on your load, environment, and budget requirements.

Q: Can I order steel components in bulk with custom branding or packaging?

A: Absolutely. We support OEM and ODM bulk orders with custom packaging and documentation tailored to your logistics needs.