The Critical Component in Product Performance

For procurement managers and product developers in the grilling industry, understanding the nuances of component quality is paramount. Among these, the cooking grate is arguably the most critical interface between the product and the end-user’s satisfaction.

While marketing often focuses on aesthetics like grill marks, a deeper, science-based understanding reveals a more complex picture. The performance of grill grates is not a matter of opinion, but a result of thermal dynamics and metallurgy.

As specialists in metal fabrication, we at YISHANG, a custom stainless steel grill grates supplier with over 26 years of manufacturing experience, believe that informed sourcing decisions are built on technical knowledge. Therefore, this guide moves beyond consumer-level advice to provide a manufacturer’s perspective on the materials that define a grill’s performance, durability, and ultimate market value.

We will analyze the science of heat transfer, the integrity of common alloys, and how these factors impact the Maillard reaction—the chemical process responsible for the rich flavor that defines a premium grilling experience. This approach will benefit commercial grill component buyers, OEM grill grates sourcing teams, and bulk purchasers seeking long-term value solutions.

Industry Realities: 3 Technical Truths That Drive Procurement Decisions

Making a sound sourcing decision requires looking past surface claims to the underlying material science. The grill grate market is filled with products engineered for cost reduction, often at the expense of performance and longevity.

To mitigate these risks, understanding these three technical realities is essential for any business aiming to deliver a superior product and minimize long-term issues like warranty claims.

Truth #1: The Science of Flavor—Prioritizing “All-Over Browning”

The visual appeal of grill marks vs flavor is a key consideration in product design. However, from a performance standpoint, these marks are evidence of intense but localized conduction.

This means only a fraction of the food’s surface benefits from the flavor-generating Maillard reaction. The larger, paler areas represent unrealized flavor potential.

In fact, maximum flavor is achieved through uniform, all-over browning, driven primarily by powerful radiant heat from the fuel source.

From a design and manufacturing perspective, this indicates that overly thick or wide grate bars can be a detriment. They physically block the radiant energy essential for developing a deep, complex flavor profile across the entire food surface. A superior design balances conductive searing with maximum exposure to this crucial radiant heat.

Moreover, choosing materials that enhance radiant transfer becomes a strategic decision for high-performance models.

Truth #2: The Stainless Steel Specification—A Critical Quality Indicator

For a wholesale buyer, the distinction between 304 vs 430 stainless steel grill grates is one of the most important quality markers. The term “stainless steel” is often used generically, but the specific alloy grade dictates the product’s lifespan and resistance to the elements.

While many mass-market grills utilize Grade 430 stainless steel, it is a ferritic steel that is magnetic and, due to its lack of nickel, significantly more susceptible to corrosion. Industry data shows that 430 grade steel can cost 25-45% less than 304 grade, making it an attractive option for budget-focused manufacturing.

By contrast, the industry benchmark for high-performance applications is Grade 304 stainless steel. Known as “18-8,” this austenitic alloy is non-magnetic and offers vastly superior corrosion resistance. It is the standard for true food grade stainless steel. A simple magnetic test for stainless steel can often distinguish the two, providing a quick quality control check during sourcing and factory inspections.

As a result, opting for 304-grade ensures lower warranty risk and longer product lifecycle.

Truth #3: The Porcelain Enamel Liability—A Cycle of Failure

Porcelain-enameled grates present a significant challenge to brand reputation due to their predictable failure cycle. While offering a low initial cost, the porcelain is a thin, glass-like coating, not a structural material.

This coating is extremely brittle and susceptible to chipping from tool impacts or thermal shock. Once the fragile coating is breached, moisture inevitably reaches the core metal, initiating rust.

As corrosion spreads, the enamel begins to flake. This raises a critical safety and liability question regarding are porcelain grates safe once compromised, as enamel fragments can contaminate food and reduce product integrity.

From a wholesaler’s point of view, this translates to a high rate of customer complaints. User reviews frequently cite a replacement cycle of just 2-3 years, leading to a high Total Cost of Ownership (TCO) for the end-user and potential damage to brand loyalty.

Consequently, this material presents hidden costs that may outweigh the initial savings.

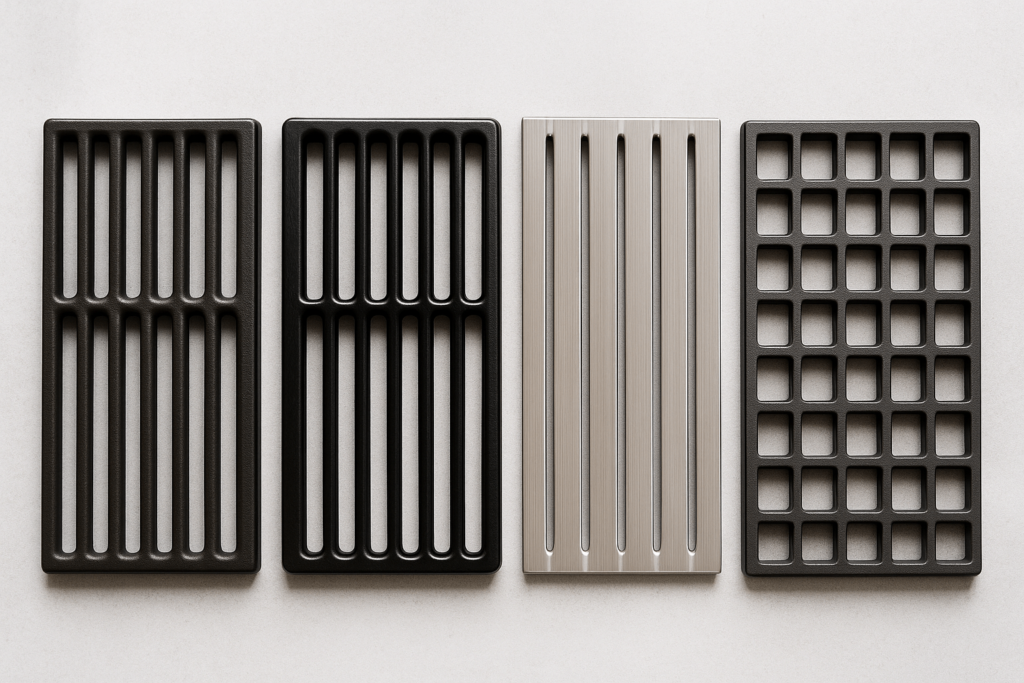

Material Analysis: A Comparative Guide for Strategic Sourcing

Selecting a grill grate material is a strategic decision. It should be based on a clear understanding of metallurgical properties and how they align with the target market’s performance expectations and price point. For buyers seeking wholesale grill components, the breakdown below serves as a technical comparison.

Cast Iron: The Thermal Powerhouse

- Procurement Profile: Ideal for premium or enthusiast-level product lines where maximum searing performance is the key selling point. Best grill grates for high heat cooking often feature raw cast iron.

- Thermal Properties: Unmatched in

heat retentionandthermal mass, making it the superior choice for high-temperature, conductive searing. - Durability & Maintenance: Extremely durable if maintained. However, its high

maintenance overhead(requiring regular seasoning to prevent rust) means it’s best suited for a dedicated end-user. - Market Segment: Grilling purists and steak enthusiasts who value performance over convenience.

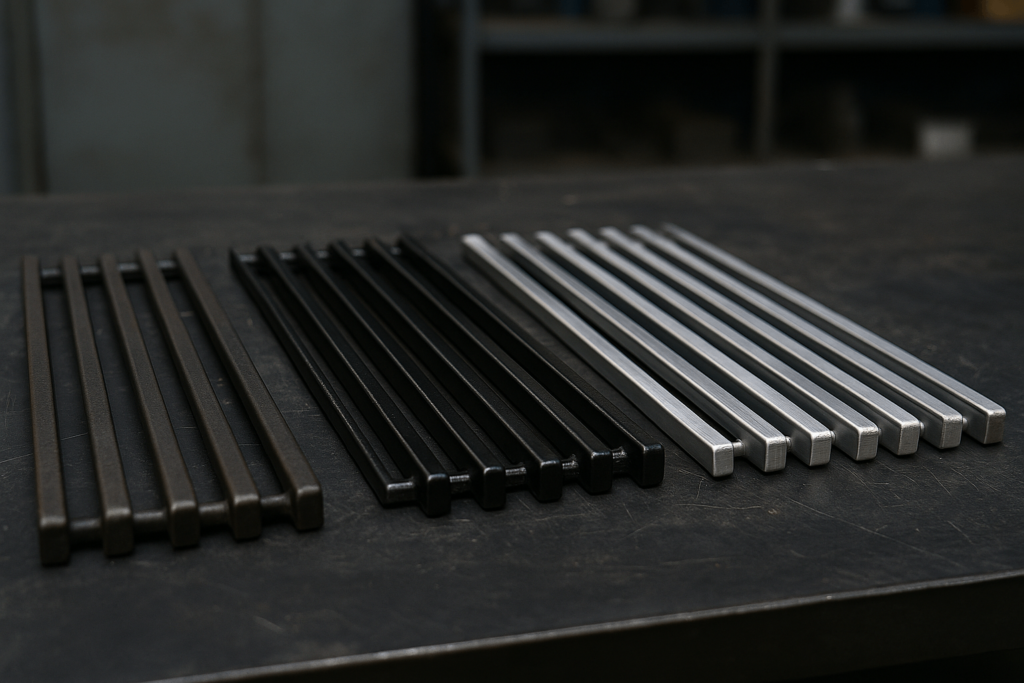

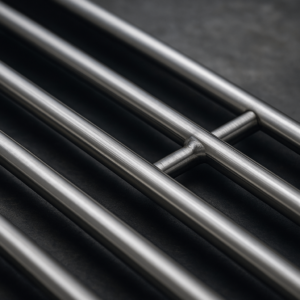

304 Stainless Steel: The Durable Workhorse

- Procurement Profile: The optimal choice for mainstream, high-quality product lines focused on durability, reliability, and low maintenance. Ideal for commercial grill grate options and custom grill grates for commercial use.

- Thermal Properties: Good heat retention, especially in

heavy dutyformats with a substantialrod thicknessof 8mm or more. - Durability & Maintenance: Excellent longevity with minimal upkeep. Its superior corrosion resistance significantly reduces customer service issues related to rust.

- Market Segment: The vast majority of grill users who seek a long-lasting, reliable, and easy-to-maintain cooking surface.

Hard-Anodized Aluminum: The Engineered Solution

- Procurement Profile: Best positioned as a premium upgrade or a key feature in a technologically advanced grill series.

- Thermal Properties: Superior

heat conductivitycompared to steel or cast iron, resulting in rapid, even heating that eliminates hot spots. An excellent option for heat-resistant metal grill grates. - Durability & Maintenance: The hard-anodized surface is extremely durable, scratch-resistant, and will never rust, offering a very low maintenance solution.

- Market Segment: Tech-savvy grillers and those looking to solve common gas grill problems like flare-ups and uneven cooking.

| Technical Specification | Raw Cast Iron | Porcelain-Enameled Cast Iron | 304 Stainless Steel (Heavy Gauge) | Hard-Anodized Aluminum |

|---|---|---|---|---|

| Thermal Mass / Heat Retention | Excellent | Good to Very Good | Good | Very Good |

| Thermal Conductivity | Slow | Slow | Fast | Very Fast |

| Material Durability | High (if maintained) | Low (coating failure is common) | Excellent | Excellent |

| Corrosion Resistance | Poor | High (until chipped) | Excellent | Excellent (Will not rust) |

| Total Cost of Ownership (TCO) | Low (if maintained) | High (due to frequent replacement) | Lowest | Low to Medium |

The Business Case for Premium & Aftermarket Components

The question are grill grates worth upgrading presents a significant market opportunity for wholesalers and manufacturers. For most grill brands, stock grates are a point of cost optimization, not performance maximization.

This creates a performance gap that can be filled with high-quality aftermarket or upgraded OEM components. An engineered system can elevate a mid-range grill’s performance to rival that of a premium model, particularly in searing capability and heat distribution.

Offering a line of premium replacement grates is a powerful value-added proposition. It addresses the pain points of existing grill owners whose stock components have failed.

The cost-benefit is clear: a single investment in a durable, high-performance grate is more economical for the end-user than repeatedly purchasing fragile, low-cost replacements. This strategy not only opens a new revenue stream but also positions a brand as a provider of quality, long-term solutions with a manufacturing backbone. For those sourcing OEM grill grates factory-direct, upgrading grill components can be a core differentiator.

Technical & Safety Specifications (FAQ)

This section addresses common technical and safety concerns, providing the clear, authoritative answers that business partners and their customers require. These insights support decision-making for commercial grill manufacturing and component upgrades.

Is a chipped porcelain enamel grate safe for use?

Once the porcelain coating is significantly chipped and flaking, it is not considered food-safe. The primary risk is foreign object contamination from hard, sharp enamel fragments.

From a business perspective, this known failure mode carries a liability risk. There is no industry-accepted, permanent method to repair porcelain grates for direct food contact. The only professionally responsible recommendation is replacement.

Why do stainless steel grates discolor? Is this a defect?

The stainless steel grill discoloration (a golden, blue, or brownish tint) is not a defect. It is a natural metallurgical phenomenon known as “heat tint” or patina.

This occurs as the chromium oxide passive layer on the surface thickens with exposure to high heat. This layer is harmless, does not affect performance, and can even enhance the grate’s non-stick properties over time.

What is the correct technical process for seasoning cast iron?

The process of “seasoning” is, in scientific terms, oil polymerization. It creates a hard, cross-linked layer of oil that bonds to the metal, providing a protective, non-stick surface.

The correct procedure for how to season cast iron grill grates involves applying a micro-thin layer of high-smoke-point oil and heating the grates to 350–400°F (177–204°C) for 30–60 minutes. This process should be repeated multiple times to build a durable initial layer.

Strategic Selection: Matching Material to Market Segment

Ultimately, the optimal grill grate material is contingent on the target market segment. For a wholesale buyer, choosing grill grates is an exercise in curating a product line that meets the needs of different end-user profiles.

- The Performance Purist Segment: This high-end user prioritizes maximum searing capability. They are the target market for heavy raw cast iron or premium hard-anodized aluminum systems.

- The Mainstream Pragmatist Segment: This is the largest market. They value durability, reliability, and low maintenance. Their needs are perfectly met by heavy-gauge (8mm+) 304-grade stainless steel grates.

- The Value-Driven Segment: This user seeks the best performance for their investment. They are the ideal customer for high-quality aftermarket upgrades that provide a significant performance leap over stock components.

By understanding the deep science behind these materials, you can make sourcing decisions that enhance product quality, build brand reputation, and drive long-term success.

For businesses seeking a manufacturing partner with a deep understanding of these materials and extensive capabilities in sheet metal cutting, CNC machining, welding, surface treatment, and assembly, YISHANG offers OEM & ODM grill component manufacturing for global wholesale clients. Contact us to discuss your specific product requirements or request a spec sheet for your next project.