In the global electronics market, the enclosure is far more than a protective shell. For procurement managers and wholesale buyers, it represents a critical sourcing decision that impacts the entire value chain—from supply chain efficiency to the final product’s market reputation.

A well-chosen enclosure ensures reliability and customer satisfaction. A poor choice can trigger a cascade of hidden costs, including warranty claims, product recalls, and damage to brand credibility.

This guide provides a manufacturer’s strategic framework for sourcing professionals. We will move beyond basic catalogs to address the core business principles of enclosure selection, using the well-known Polycase brand as a reference to explore a fundamental question: when is a standard enclosure the right tool, and when does your product line require the superior quality and long-term value of a custom fabrication partner or an OEM metal enclosure manufacturer?

Part 1: The First Principles – An Enclosure as a Business Risk Decision

The Cost of “Good Enough”: A Business Risk Analysis

Before evaluating materials, it is essential to quantify the business risks of an under-specified enclosure. These are not just technical issues; they are financial liabilities that can impact profitability.

Imagine an electronic enclosure failure in a large-scale deployment of agricultural IoT sensors. If the housing isn’t truly rated for prolonged UV exposure and submersion, it could lead to widespread field failures, triggering a costly product recall and a significant loss of market trust. A bulk enclosure supplier that understands outdoor deployment risk would mitigate this.

In an industrial setting, a controller with inadequate EMI shielding can cause erratic machine behavior, leading to production stoppages for your end customer and damaging your reputation for reliability. These incidents highlight a critical truth for any volume buyer: the enclosure is an active component in your product’s market success.

The sourcing decision is a risk management strategy that directly impacts system reliability and the total cost of ownership. The initial savings from a cheaper housing are often erased by the long-term expenses of field service and replacements. A commitment to long-term durability is the foundation of a profitable and reputable product line.

Part 2: The Core Decision – The Great Debate: Metal vs. Plastic

The most fundamental decision in enclosure material selection revolves around the material itself. This choice dictates physical properties, thermal performance, and crucial cost factors that affect your bottom line.

The debate of metal vs plastic enclosures is not about which is universally “better,” but which is strategically correct for a specific product line. As fabricators, we can provide insight into the distinct engineering trade-offs that impact your sourcing decision.

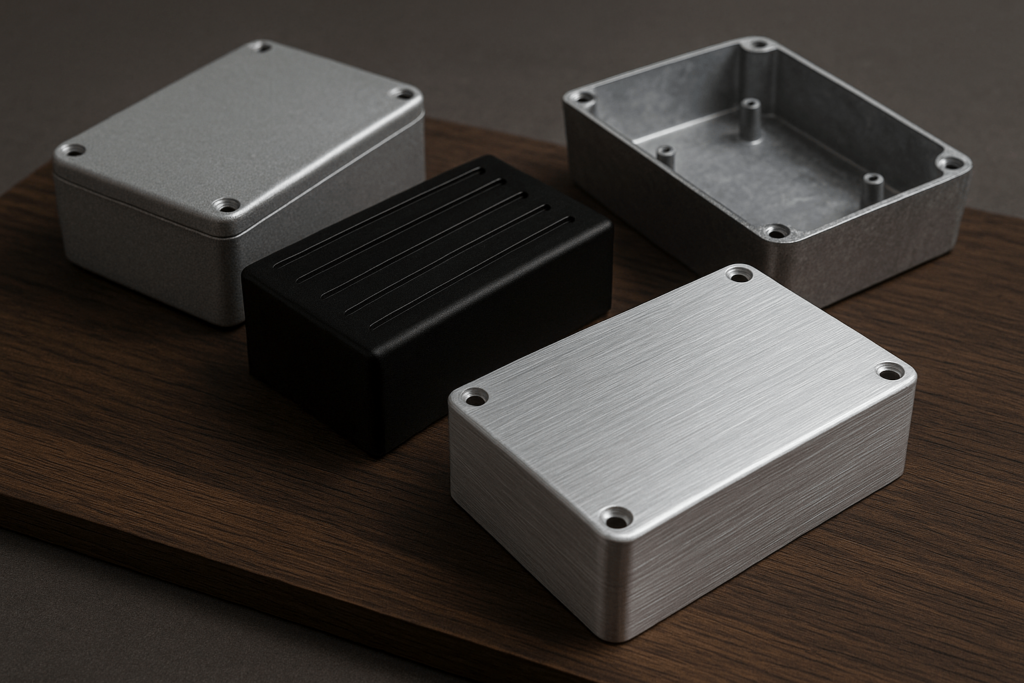

Die-Cast Aluminum: The Fortress for High-Value Applications

From a manufacturing and procurement standpoint, a die-cast aluminum enclosure is the definitive choice for high-value equipment where reliability is paramount. Its primary advantage is its inherent EMI/RFI shielding.

The conductive nature of aluminum creates a natural Faraday cage, blocking ambient interference. For a wholesaler, this translates directly into a more reliable product with a lower rate of field failures, protecting your brand’s reputation for quality.

Furthermore, aluminum excels at thermal management. Its ability to dissipate heat can eliminate the need for fans, reducing the bill of materials (BOM), simplifying assembly, and removing a common point of failure.

Combined with its exceptional impact resistance, a rugged aluminum housing ensures the longevity of the product inside. Whether it’s an industrial control panel enclosure or a heavy-duty automotive controller, standardized aluminum enclosures such as the Polycase AN Series exemplify this combination of thermal and mechanical robustness.

Engineering Plastics (Polycarbonate & ABS): The Versatile Champions

While metal provides ultimate durability, an objective analysis reveals clear advantages for plastics in specific contexts. The primary distinction in the polycarbonate vs ABS enclosures debate is market application.

Polycarbonate is the champion for modern outdoor and wireless products. Its excellent UV resistance prevents the material from degrading after years of sun exposure, a key factor for product longevity.

Critically for the booming IoT market, polycarbonate offers near-perfect RF transparency, allowing wireless signals to pass through unhindered. This enables antennas to be housed safely inside a waterproof enclosure, an essential feature for reliable sensor performance. It’s ideal for a custom enclosure for agriculture sensor systems or remote telemetry units.

Acrylonitrile Butadiene Styrene (ABS) is a highly cost-effective plastic box best suited for high-volume, price-sensitive indoor applications. While lacking the resilience of polycarbonate, it is lightweight and offers a clean aesthetic finish, making it ideal for desktop and consumer electronics.

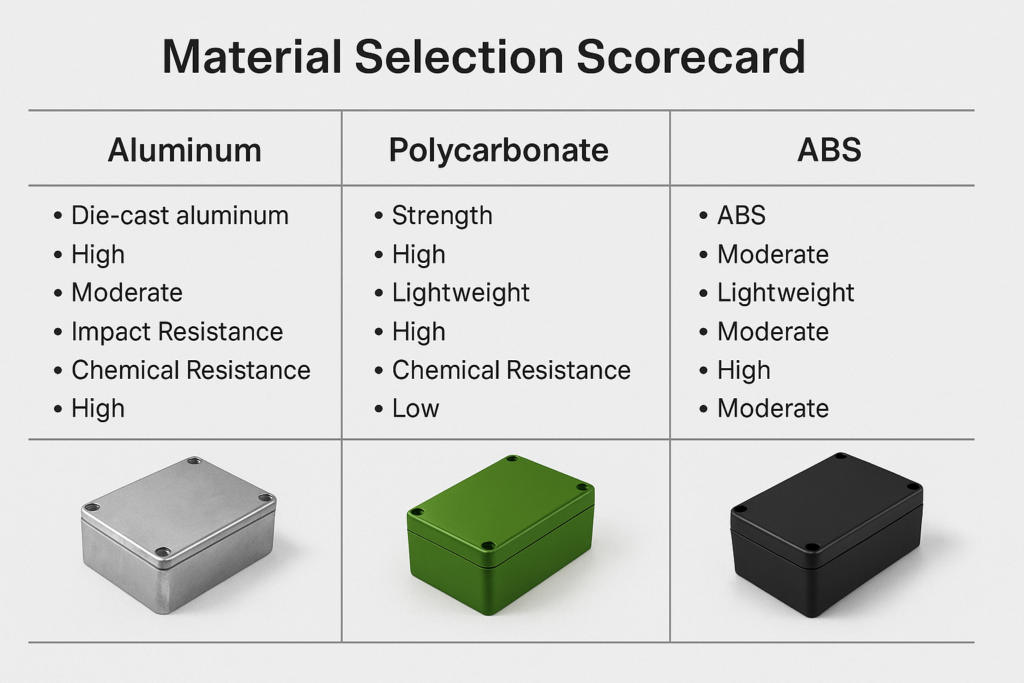

The Material Selection Scorecard: A Sourcing Decision Tool

To simplify this critical decision, the table below provides a visual summary of key performance and business criteria. This material selection scorecard acts as a powerful guide for sourcing professionals.

| Performance CriterionDie-Cast AluminumPolycarbonate (PC)Acrylonitrile Butadiene Styrene (ABS) | |||

|---|---|---|---|

| EMI/RFI Shielding | Excellent | None | None |

| Thermal Conductivity | Excellent (Dissipates Heat) | Poor (Insulator) | Poor (Insulator) |

| Impact Strength | Excellent | Very Good | Moderate |

| UV Resistance | Excellent (with coating) | Excellent | Poor |

| RF Transparency | None (Blocks Signals) | Excellent | Excellent |

| Suitability for High Volume | Good (Die-Casting) | Excellent (Injection Molding) | Excellent (Injection Molding) |

| Relative Unit Cost | High | Medium | Low |

Part 3: The Rules of the Game – NEMA & IP Ratings from a Fabricator’s Perspective

Once the material is chosen, the next step is quantifying the required protection level. For international wholesalers, a deep understanding of the nuances between NEMA vs IP ratings is crucial for ensuring global compliance, market access, and avoiding liability.

NEMA & IP Ratings: A Practical Field Guide

The two dominant electrical enclosure ratings are NEMA (National Electrical Manufacturers Association) for North America and IP (Ingress Protection) for international markets.

The IP rating system, defined by IEC 60529, uses a two-digit code to classify protection against solids and liquids. An

IP66 waterproof metal box, for example, means an enclosure is dust-tight (6) and can withstand powerful water jets (6).

NEMA ratings, governed by NEMA 250, are more holistic. The

NEMA 4X meaning, for instance, goes beyond being watertight; the “X” designates tested protection against corrosion, essential for products in marine or agricultural markets.

The Critical Difference for Global Sourcing

A common oversimplification is to treat the two systems as directly convertible. While a NEMA 4X enclosure generally meets IP66 requirements, the NEMA vs IP comparison is more complex.

NEMA standards often mandate tests not found in the IP system, such as the ability to remain undamaged by external ice formation.

From a procurement and compliance perspective, this is a critical distinction. A product intended for the North American market may require a specific NEMA rating for regulatory acceptance, even with an equivalent IP rating. Understanding these regional differences is key to ensuring your products are compliant in their target markets.

A Note on Modifications: Protecting Your Certification and Liability

Here is a crucial insight from a fabricator that directly impacts quality control: an enclosure’s rating is only valid for the unmodified unit. Every cutout made after certification can compromise the seal.

Maintaining a rating on a modified unit requires a controlled process. Every added component, from cable glands to switches, must match the enclosure’s original rating.

This is why sourcing from a partner with professional modification capabilities is essential. It ensures the final product you receive still meets the advertised protection standards, protecting you and your customers from liability. At YISHANG, our ISO 9001 certified processes guarantee this consistency.

Part 4: The Final Choice – Standard Off-the-Shelf vs. Custom Metal Fabrication

With a firm grasp of materials and ratings, the final strategic decision emerges: should you source a standard enclosure or partner with a manufacturer for a custom-fabricated solution? This choice between custom vs standard enclosure balances upfront speed against long-term performance and brand value.

The Power of Standard Enclosures: When Polycase is the Right Tool

Standard, off-the-shelf enclosures offer clear advantages, and brands like Polycase serve this need effectively. Their primary benefits are speed and low upfront cost, especially for

rapid prototyping and low-volume runs.

The ability to order a standard box for immediate shipment is invaluable for design validation without committing to tooling. For many straightforward applications where a standard size is a good fit, this is the most logical and economical choice.

Furthermore, vendors like Polycase offer valuable customization services on their standard boxes, providing a convenient one-stop shop for basic modifications. This approach is ideal when time-to-market is the primary driver.

The Hidden Costs of “Standard”: Recognizing the Limits

For volume production, procurement managers often encounter the significant standard enclosure limitations. The most common issue is a dimensional mismatch, forcing the use of an oversized enclosure.

This leads to wasted space and, more importantly, increased material and shipping costs across thousands of units. For a

custom PCB enclosure, where density is a competitive advantage, this is a major drawback.

Another hidden cost lies in assembly. Fixed internal mounting bosses that don’t align with your PCB require adapters or mounting plates, adding complexity, cost, and time to your assembly line. These seemingly small issues often escalate the Total Cost of Ownership (TCO) beyond initial projections.

The Custom Fabrication Advantage: A Partnership for a Superior Product

When the limitations of a standard box compromise your product’s quality or profitability, custom metal fabrication becomes the superior strategic choice. This approach is a partnership to create a housing that is an optimized part of your product.

With a custom aluminum enclosure from a partner like YISHANG, you achieve total design freedom. The enclosure is built to your exact specifications, ensuring a perfect fit that reduces overall product size and shipping costs.

Mounting points and PEM inserts are integrated directly into the design, simplifying your assembly process and reducing labor costs. This Design for Manufacturability (DFM) approach creates a cleaner final product with built-in efficiency.

This level of precision enhances your brand perception and delivers a better long-term ROI for your entire product line.

Part 5: Conclusion – A Final Checklist for Your Next Sourcing Decision

Choosing the right enclosure is a strategic sourcing decision. For prototyping, a standard enclosure is a fast, effective solution. But for mission-critical product lines where quality, efficiency, and brand reputation are paramount, custom metal fabrication is the superior business choice.

Your Sourcing Decision Checklist

To guide your specification process, use this simple enclosure selection checklist:

- Step 1: Define Your Market & Environment. Analyze compliance needs (NEMA vs. IP) and operational hazards to determine the required protection rating.

- Step 2: Define Your Brand Position & Core Function. Consider how material choice (e.g., rugged aluminum vs. lightweight plastic) reflects your brand’s quality and supports the product’s function.

- Step 3: Analyze Assembly & Logistics. How will a perfectly sized enclosure impact assembly time, shipping volume, and labor costs?

- Step 4: Evaluate the Total Cost of Ownership. Does a standard enclosure’s compromises lead to higher long-term costs (assembly, shipping, warranty claims)? Or does the investment in a custom metal enclosure solution provide a lower TCO?

The Fabricator’s Recommendation

For rapid prototyping, a quality off-the-shelf product is a smart choice. For volume production where precision and reliability are non-negotiable, a partnership with an expert metal fabricator is the superior path.

If your product line demands more than a standard box can offer, contact our engineering team. Let’s discuss how a custom metal enclosure partnership can enhance your product and your bottom line.

Frequently Asked Questions (FAQ)

Q1: What is the best enclosure for outdoor industrial use?

A: A die-cast aluminum enclosure with a NEMA 4X or IP66 rating is typically the best choice for outdoor industrial use due to its corrosion resistance, durability, and weatherproof performance. This type of weatherproof electrical enclosure box provides long-term protection in harsh conditions.

Q2: Are custom metal enclosures worth the investment for large-volume production?

A: Yes. For high-volume production, a bulk custom enclosure order can lower total costs through optimized fit, reduced material waste, and improved assembly efficiency. The long-term savings often outweigh the higher initial tooling costs.

Q3: Can plastic enclosures be used for wireless or RF applications?

A: Absolutely. Polycarbonate and ABS enclosures are excellent for wireless devices because they are RF transparent. These are widely used in IoT deployments, including as custom enclosure for agriculture sensor applications and remote telemetry units.

Q4: What’s the difference between an OEM enclosure and off-the-shelf models?

A: An OEM enclosure is designed specifically for your application and product dimensions, typically by a sheet metal box supplier like YISHANG. Off-the-shelf models are pre-made and faster to deploy but may require costly modifications or create inefficiencies in high-volume production.

Q5: How do I find a reliable enclosure manufacturer in China?

A: Look for companies with certifications like RoHS and ISO 9001, strong export experience, and in-house capabilities for CNC machining, welding, powder coating, and assembly. A trusted enclosure manufacturer China partner should offer both standard and fully custom services to support your growth.