The Engineer’s Common Misconception: Why IP67 is Not Always the “Upgrade” to IP66

In engineering and procurement, a common and potentially costly misconception arises from a simplistic comparison of numbers. When selecting a metal enclosure for a critical application, a project manager might face two options: one rated IP66, the other IP67. It seems logical to assume the IP67 enclosure rating is inherently superior. After all, seven is greater than six.

This seemingly straightforward assumption, however, reflects a fundamental misunderstanding of the Ingress Protection (IP) standard. Such thinking can result in significant over-engineering and unnecessary project costs—or worse, a catastrophic failure of the equipment the enclosure is designed to protect. The issue of IP66 vs IP67 is not a linear escalation of quality.

Instead, it represents a precise, application-driven decision between two very different types of liquid ingress protection. This is not a debate of “good” versus “better,” but of choosing the right defense strategy for a specific environmental hazard. An IP66 electrical enclosure is built to withstand the impact of dynamic, high-pressure water jets, whereas an IP67 electrical enclosure is engineered to resist the uniform, static pressure of temporary submersion.

Each scenario places distinct demands on a metal enclosure’s structural design and sealing performance. This guide breaks down those differences, offering a comprehensive framework—from a quick decision-making tool to an in-depth look at seal failure physics—so you can select the most suitable, reliable, and cost-effective “armor” for your valuable equipment.

30-Second Decision Table: Which Rating Do You Really Need?

If you’re pressed for time and need a rapid selection guide, this table summarizes the practical differences between IP66 and IP67 enclosures in real-world engineering terms. Use this as a quick reference to determine which rating aligns best with your project’s environment and risk profile:

| Factor | IP66 Enclosure | IP67 Enclosure |

|---|---|---|

| Water Protection Type | High-pressure water jets from all directions | Temporary full submersion in water |

| Typical Use Case | Outdoor control panels, washdown areas, equipment near machinery with spray | Underground sensors, flood-prone areas, brief immersion scenarios |

| Dynamic Water Resistance | Excellent | Limited |

| Static Water Resistance | Moderate | Excellent |

| Seal Design Focus | Resilience under directional force | Seal compression under constant pressure |

| Cost & Complexity | Generally simpler and lower cost | Slightly higher cost due to sealing requirements |

This table is not a substitute for full system design analysis but offers a high-level overview to help engineers and purchasing managers filter options before deeper technical vetting.

A key insight: IP66 is superior for environments involving high-pressure spray or directional jets, while IP67 excels in scenarios with potential submersion, even if brief and infrequent. Confusing the two can lead to enclosures that fail during high-pressure cleaning or accumulate condensation due to over-sealing.

In the following sections, we’ll go beyond surface-level summaries and explain how each standard works, how tests are conducted, and what those numbers mean for actual engineering performance and procurement decisions.

Understanding the IP Code: Breaking Down the Digits

The Ingress Protection (IP) rating system is governed by the IEC 60529 international standard and consists of two digits:

- The first digit refers to solid particle protection (e.g., dust).

- The second digit refers to liquid ingress protection (e.g., water).

Let’s break down IP66 and IP67:

| Rating | First Digit (6) – Dust Protection | Second Digit – Water Protection |

|---|---|---|

| IP66 | Dust-tight: complete protection against dust ingress | Protection against powerful water jets (12.5 mm nozzle) from any direction |

| IP67 | Dust-tight: same as above | Protection against temporary immersion up to 1 meter for 30 minutes |

The key point is that both ratings offer the same highest-level dust protection: “6” means the enclosure is dust-tight and passes a vacuum-based talcum powder test with zero ingress.

Where they diverge is the second digit. Here’s how the difference plays out:

- IP66 must withstand high-pressure directional water jets.

- IP67 must survive full submersion under standardized static water pressure.

These test conditions are not interchangeable and represent distinct environmental threats. This is where procurement teams must consider not just the severity of water exposure, but its physical characteristics—dynamic impact vs. static immersion.

IP ratings do not imply cumulative protection. An IP67 enclosure may fail under water jets, while an IP66 enclosure may leak when submerged.

That’s why engineering teams should always align enclosure ratings with the precise conditions of installation, maintenance practices, and exposure risks—not just assume “higher number = better.”

How the Tests Are Conducted: Spray vs. Submersion

Understanding how each rating is tested helps clarify their respective strengths and limitations.

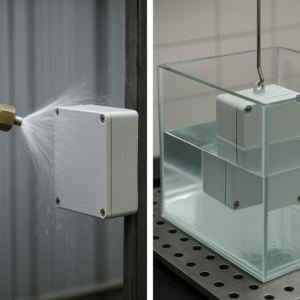

IP66 Water Jet Test (IEC 60529):

- The enclosure is exposed to powerful water jets from a 12.5 mm diameter nozzle.

- Water flow rate: 100 liters/minute.

- Distance: 2.5 to 3 meters from the enclosure.

- Duration: Minimum 3 minutes per surface area.

The goal is to simulate intense directional water spray, such as washdown procedures in industrial environments or outdoor storms with wind-driven rain.

IP67 Immersion Test (IEC 60529):

- The enclosure is fully submerged in water at a depth of up to 1 meter.

- Duration: 30 minutes.

- Water must be still (no turbulence or flow).

This test simulates static flooding conditions, such as equipment accidentally left in water during heavy rainfall or buried enclosures in saturated soil.

Key Differences:

- IP66 replicates aggressive mechanical water force.

- IP67 tests uniform hydrostatic pressure without directional impact.

These differences result in very different seal behaviors. Gaskets and sealing surfaces that hold up under spray may not tolerate long-term immersion pressure. Likewise, an immersion-optimized seal may not resist jet impact, especially at seams or hinges.

For this reason, manufacturers often design enclosures with distinct sealing strategies depending on the intended rating—such as reinforced flange lips for spray deflection (IP66), or deep cover sealing grooves for immersion resilience (IP67).

Engineering Focus: What Fails First in Real-World Applications

In practice, failure rarely originates from the metal housing itself—it comes from the seal interface, where gaskets, seams, and covers must preserve an airtight and watertight bond under stress.

For IP66, repeated directional impact from high-pressure water causes wear on:

- Door gaskets, especially around hinge points.

- Latch points where seal compression is uneven.

- Corners or edges where spray rebounds at oblique angles.

For IP67, failures often result from:

- Long-term seal compression fatigue (also called compression set).

- Water seepage through microscopic gaps formed under pressure.

- Material incompatibility with stagnant water or fluctuating temperatures.

Understanding these failure modes allows design engineers to specify:

- Appropriate gasket material (e.g., silicone, EPDM, neoprene).

- Optimal sealing geometry, such as tongue-and-groove or double-lip designs.

- Surface treatments or coatings to prevent corrosion at mating surfaces.

IP ratings certify initial performance, but do not account for lifecycle wear. A metal enclosure may pass IP67 testing when new but degrade under thermal cycling, UV exposure, or vibration in real-world conditions.

This is where engineering judgment outweighs test reports. Environments with frequent jet spray should prioritize sealing resilience over immersion performance. Conversely, burial in wet soil or low-lying installation areas should favor immersion sealing.

A thorough understanding of failure mechanisms helps engineers design for longevity, not just certification.

Total Cost of Ownership: Avoiding Over-Engineering

While the instinct to choose the “higher” rating may appear cautious, over-specifying an IP67 enclosure where IP66 would suffice can inflate project costs without delivering real benefits.

Here’s where cost factors enter:

- Tooling complexity: IP67 enclosures often require deeper covers, tighter machining tolerances, and more complex gasket channels.

- Material costs: Enhanced seals and additional fastening systems increase raw material usage.

- Production throughput: Assembly and QA for IP67-rated products take longer, potentially slowing down delivery.

If the operating environment only involves water spray (e.g., from cleaning or open weather), an IP66 enclosure will likely outperform IP67 under real conditions and save significantly on manufacturing and maintenance.

Over-engineering can also result in unexpected side effects:

- Seal overcompression from unnecessary torque on fasteners.

- Condensation buildup due to lack of breathability in IP67 setups.

- Heavier enclosure weight, impacting mounting systems and transportation.

Smart procurement and design teams weigh not only the protection rating but its relevance, lifecycle cost, and integration complexity. The goal is not to “win on specs,” but to achieve long-term system performance and maintainability within budget.

Beyond IP: Considering NEMA, IK, and Chemical Resistance

While IP ratings are the most recognized standard globally, engineers working across regions or in specialized environments must also consider other protection schemes such as:

NEMA Ratings (U.S.-Centric)

The National Electrical Manufacturers Association (NEMA) rating system is commonly used in North America. Unlike IP, which focuses solely on ingress, NEMA covers additional parameters such as:

- Corrosion resistance

- Construction material integrity

- Gasket aging

- Environmental hazards (e.g., icing, oil exposure)

Although not directly equivalent, here’s a rough IP-to-NEMA alignment:

- IP66 ≈ NEMA 4 or 4X

- IP67 ≈ NEMA 6 or 6P

For outdoor or corrosive applications (marine, petrochemical), NEMA 4X may offer superior material protection, especially with stainless steel construction.

IK Ratings (Mechanical Impact Resistance)

Neither IP66 nor IP67 addresses mechanical impact. For that, the IK rating (per IEC 62262) defines how well an enclosure withstands physical blows:

- IK08: Protected against 5-joule impact (1.7 kg dropped from 300 mm)

- IK10: Protected against 20-joule impact (5 kg dropped from 400 mm)

Outdoor, public-facing, or industrial installations may require IP66/IK10 or IP67/IK10 combinations to prevent vandalism or accidental damage.

Chemical and UV Resistance

Ingress ratings do not account for chemical or UV degradation. For environments involving:

- Cleaning solvents

- Salt spray

- Acidic or alkaline exposure

- Direct sunlight (UV)

You must specify:

- Resistant coatings (e.g., polyester powder coating, anodizing)

- Material compatibility (e.g., stainless steel 316L vs. aluminum)

- Sealing compound resistance

Failure to match these criteria can lead to long-term enclosure degradation, even if IP or NEMA criteria are initially met.

Summary

While IP66 and IP67 address water and dust ingress, they are only part of the picture. For truly resilient enclosures, procurement decisions should factor in regional standards, mechanical durability, and environmental compatibility.

YISHANG’s engineering team routinely assists clients with multi-factor enclosure specification—including IP, NEMA, IK, and chemical resistance—so that the final product doesn’t just pass a test, but survives in real-world use.

Final Thoughts: Matching Protection to Purpose

Choosing between IP66 vs. IP67 should not be about chasing the higher number, but about engineering precision. The right enclosure rating aligns directly with how, where, and why your equipment will operate.

If your environment involves high-pressure hosing or directional jets, IP66 is often more effective and cost-efficient. If you expect temporary submersion or installation below grade, IP67 is the safer bet. But neither tells the full story without factoring in lifecycle stresses, mechanical risks, or chemical exposures.

Ultimately, the goal is not just certification—it’s real-world resilience. A properly rated enclosure means less maintenance, fewer failures, and longer uptime for your system.

At YISHANG, we go beyond spec sheets. Our engineers collaborate with global OEMs, integrators, and industrial designers to create tailored enclosure solutions that meet both regulatory and environmental challenges.

Contact our team today to discuss your project’s requirements. Whether you need 500 weatherproof control boxes or 5,000 precision-machined sensor housings, we’re here to help you build smarter.