Introduction: From “Rule of Thumb” to Physical Law

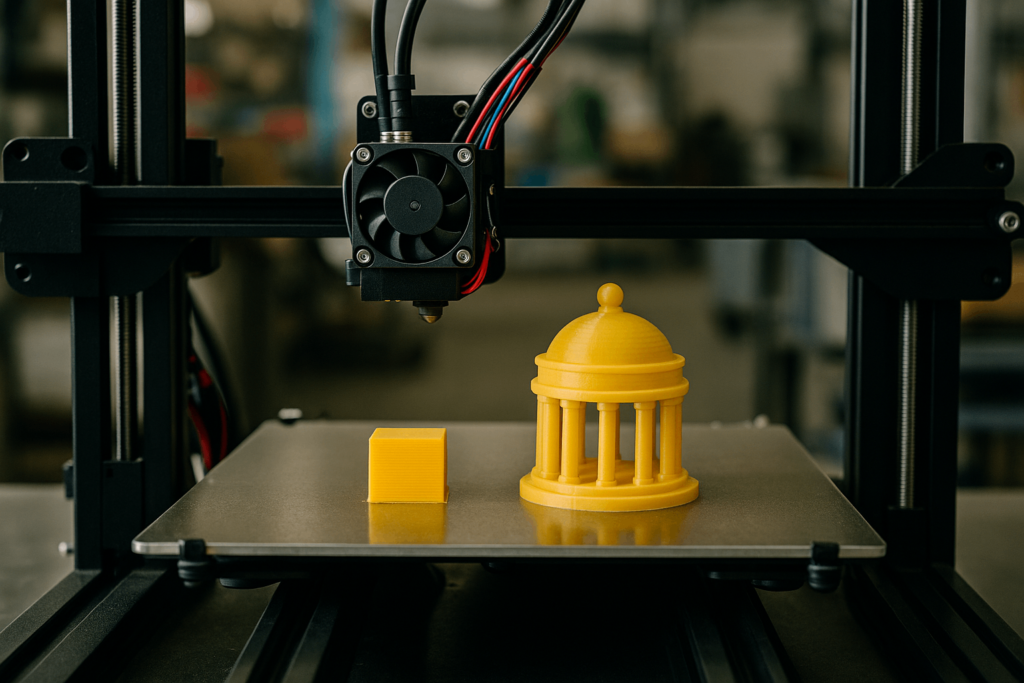

In Fused Deposition Modeling (FDM), the advice to set PLA bed temperature to 60°C is ubiquitous. While a safe starting point, in precision manufacturing, “safe” is rarely sufficient, as persistent failures like warping and dimensional inaccuracy are not random—they are predictable outcomes of mismanaged thermal stress. These challenges mirror the complexities in industrial metal fabrication.

This guide moves beyond simple numbers. We will deconstruct the material science to provide a repeatable framework for first-layer thermal management, ensuring your prototypes achieve perfect dimensional accuracy from the start. This same methodology is routinely adopted in YISHANG’s engineering workflows to ensure reliability across varied batch runs and meet the stringent expectations of international wholesale buyers seeking process-stable PLA part manufacturing.

The Engineer’s Decision Matrix for PLA Bed Temperature

For efficient application in a production or prototyping environment, a direct, scenario-based reference is essential. This matrix provides a scientifically grounded starting point for various engineering applications.

| Application Scenario | Core Engineering Challenge | Recommended Bed Temp | Governing Physical Principle |

|---|---|---|---|

| General Prototyping | Balancing adhesion & dimensional accuracy | 60°C | The equilibrium point, near PLA’s Glass Transition Temperature (Tg) |

| Large, Flat Structural Parts | High cumulative thermal stress, prone to warping | 65–70°C | Maintains the base in a pliable “rubbery” state to absorb and dissipate stress |

| Small, High-Detail Components | Excessive localized heat accumulation, base deformation | 50–55°C | Prevents the base from becoming overly soft, mitigating the “elephant’s foot” defect |

| High-Speed Printing (>150mm/s) | Reduced thermal bonding time | ~65°C | Increases molecular chain activity to accelerate mechanical interlocking with the build plate |

These parameters reflect empirical insights validated through hundreds of FDM prototypes at YISHANG’s lab, supporting both internal R&D iterations and external client samples.

The Physics of the First Layer: A Thermal Stress Management System

To control a manufacturing process, one must understand the governing physics. The heated bed is an active thermal control system designed to manage the material’s physical state and combat immense internal forces.

The Critical State: Understanding Glass Transition Temperature (Tg)

The single most important concept is the Glass Transition Temperature (Tg). This is not a melting point. It is the temperature range where a polymer like PLA transitions from a hard, rigid “glassy” state to a soft, pliable “rubbery” state.

For most PLA formulations, this occurs around 55–65°C. Below this, polymer chains are locked and brittle. Above it, they can slide past one another, allowing the material to deform without fracturing.

This rubbery state is the key to a robust mechanical bond. When held at its Tg, the extruded PLA is malleable enough to flow into the microscopic topography of the build plate, maximizing surface contact and creating a powerful physical anchor.

This principle—maximizing mechanical interlocking at Tg—has been validated repeatedly in YISHANG’s R&D calibration workflows for early-stage prototyping. For production buyers sourcing printed jigs or fixtures, the ability to repeat this interlocking consistently is what translates to dimensional reliability at scale.

The Unseen War: How Thermal Contraction Creates Catastrophic Stress

Every FDM print battles thermal contraction. Plastic is extruded hot (190–220°C) and immediately cools, causing its polymer chains to pack tightly and the material to shrink. While PLA’s shrinkage is low (0.3–0.5%), it generates immense cumulative force.

The problem is the thermal gradient—the temperature difference between the anchored first layer and the rapidly cooling upper layers. The contracting upper portion pulls inward on the solidified base, generating powerful internal stresses.

This phenomenon is directly analogous to stresses that cause deformation in metal castings or welds. These forces concentrate at sharp corners, creating a lever effect that pries the print from the bed, resulting in warping. It is this stress distribution that makes thermal control not merely a best practice, but an engineering requirement.

For procurement teams evaluating sample quality consistency, understanding this thermal warpage mechanism is essential in benchmarking print vendors.

Variable Control: Precision Calibration for Your Equipment

The optimal temperature is a function of the entire system. The number set in the slicer is an input; the actual thermal conditions at the first layer are the output, heavily influenced by hardware and environment.

The Build Plate Interface: Glass vs. PEI Coated Steel

The build surface is an active component in the thermal system.

Glass build plates offer exceptional flatness and a mirror finish. With a high thermal mass, glass heats slowly but distributes temperature very evenly, minimizing stress-inducing hot spots. However, as a thermal insulator, it can struggle to maintain temperature if exposed to drafts.

PEI (Polyetherimide) on spring steel is the modern engineering standard. The steel base has high thermal conductivity for rapid heating, while the PEI coating offers superior adhesion. This efficiency means an operator might achieve the same warp resistance at 55°C that a glass bed requires 65°C to achieve.

At YISHANG, we validate all surface-material combinations using both thermographic and functional adhesion tests to ensure repeatable bonding. When producing batch prints for assembly fixtures or test-fit components, this calibration ensures that adhesion performance remains stable across volume runs.

Material Consistency: A Process Control Variable

In a manufacturing context, material consistency is paramount. “PLA” represents a broad category of polymer blends. Each manufacturer’s formulation of additives and colorants can slightly alter the filament’s precise Tg.

Dark pigments, for instance, absorb and radiate thermal energy differently than light ones. For applications where tight tolerances are critical, re-calibrating for each new material batch is a necessary step in maintaining process control.

This recalibration approach is embedded in YISHANG’s SOP for print validation and sample verification, especially when producing client prototypes for sectors like consumer electronics or metal housing pre-fit trials.

Failure Mode Analysis: A Systematic Approach to Defects

First-layer failures are not random; they are predictable failure modes that can be systematically corrected.

Failure Mode 1: Warping (Adhesive Force < Internal Stress)

Warping occurs when the bed temperature is too low, causing the first layer to cool below its Tg. In this rigid state, it cannot absorb the pulling stress from above, and the part deforms.

A systematic, three-step solution should be employed:

- Interface Preparation: Surface contamination is the primary cause of adhesion failure. While isopropyl alcohol (IPA) is a solvent that can thin and spread oils, a wash with warm water and a basic dish soap is superior. The soap acts as a surfactant, bonding to oil molecules and washing them away completely.

- Parameter Adjustment: With a clean surface and correct Z-offset, increase the bed temperature in 5°C increments. This brings the first layer into its optimal pliable state.

- Mechanical Anchoring: For large parts, a brim—a single-layer extension around the model’s base—dramatically increases surface area, providing a powerful mechanical anchor to counteract lifting forces.

These techniques are part of YISHANG’s standard print troubleshooting guide to ensure prints used for functional metal-part placeholders do not suffer dimensional compromise.

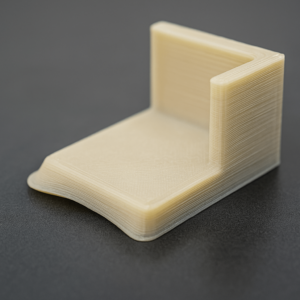

Failure Mode 2: Elephant’s Foot (Print Weight > Foundational Support)

This defect is a bulge at the print’s base, caused by a bed temperature that is too high. The initial layers remain too soft and are compressed by the weight of the subsequent layers.

Resolving this also follows a systematic approach:

- Mechanical Calibration: First, verify the Z-offset is not too low. A nozzle that is too close will mechanically force filament outwards, exacerbating the issue.

- Parameter Adjustment: Lower the bed temperature in 5°C increments. This allows the initial layers to become firm enough to support the print’s weight without deforming.

- Software Compensation: Modern slicers offer a precision solution. Settings like “Initial Layer Horizontal Expansion” allow a negative offset (e.g., -0.15 mm) to be applied, counteracting the physical bulge to produce a perfectly vertical wall.

YISHANG uses this method particularly when printing for display stands or dimensional references that require upright visual fidelity.

Advanced Process Control: Mastering the First Layer

Industrial-grade repeatability requires moving from reactive troubleshooting to proactive process control. This involves empirical calibration and a holistic understanding of how slicer parameters work in concert.

Empirical Calibration: The Role of the Temperature Tower

A temperature tower is a calibration print that systematically tests a range of temperatures to find the optimal value for a specific filament. The process involves using a slicer’s post-processing scripts to insert G-code commands that change the nozzle temperature at specific layer heights.

Interpretation is a two-stage process. First is a visual inspection for stringing and surface finish. More critical for functional parts is a destructive physical test. Attempt to break the tower apart at each temperature section.

The ideal temperature is often not the one that looks prettiest. Instead, it is the lowest temperature that exhibits excellent layer adhesion—where the part breaks across layers rather than cleanly separating along them. This ensures maximum mechanical strength.

YISHANG’s prototyping division applies this method for all customer-specific filament requests, particularly for international buyers who request tight tolerance samples for quotation or OEM validation.

The Coordinated Process: Temperature, Speed, and Cooling

Moreover, the interaction of multiple slicer parameters must be controlled:

- Initial Layer Temperature Strategy: To create a strong “weld,” set the initial layer bed temperature 5–10°C hotter than for subsequent layers. After the foundation is set, the temperature can drop to a maintenance level, reducing energy use and preventing radiant heat from affecting upper layers.

- Initial Layer Print Speed: A slow first layer speed (20–30 mm/s) is non-negotiable for maximum adhesion. This allows ample time for thermal energy transfer and a strong, uniform bond to form.

- Part Cooling Fan Control: The part cooling fan must be disabled for the first one to three layers. Activating the fan too early introduces thermal shock, directly counteracting the heated bed’s purpose and driving warping.

These settings are part of YISHANG’s default slicing profiles used in bulk print jobs for clients requiring multiple test iterations or batch sampling.

Common PLA Bed Temp Issues & Solutions for Engineering Buyers

Many technical buyers search for highly specific failure scenarios. Below are commonly searched PLA bed temperature problems and keyword-targeted solutions:

- How to fix PLA warping on glass bed: Use a brim, increase temperature by 5°C, and ensure detergent-cleaned surface.

- Best PLA bed temp for large prints: 65–70°C with slow cooling and enclosure; ideal for fixtures or large prototype shells.

- How to prevent elephant’s foot in PLA: Lower bed temp to 50–55°C, adjust Z-offset, or use slicer’s negative horizontal expansion.

- Recommended settings for high-speed PLA printing: Use ~65°C bed temp and reduce fan speed for first layers.

- Why PLA first layer doesn’t stick on PEI: Clean bed thoroughly, recalibrate Z-offset, and disable fan initially.

These solutions support engineers tasked with qualifying repeatable print vendors or setting up in-house prototypes.

Frequently Asked Questions (FAQ)

- Q1: Is a heated bed absolutely required for PLA? While small prints can succeed without one, a heated bed is essential for reliable, high-quality printing. It is the primary tool for preventing warping by managing internal stress.

- Q2: My print is still warping at 70°C. What is the next step? If warping persists, the root cause is likely not temperature alone. Re-verify surface cleanliness with soap and water, and ensure your Z-offset is perfectly calibrated. For large parts, a brim is a highly effective mechanical solution.

- Q3: Why do my prints stick too well to my PEI or glass bed? For glass, allow the bed to cool completely to room temperature; the part will often self-release. For PEI, excessive adhesion may indicate your Z-offset is too low, pressing the filament too aggressively into the surface.

- Q4: How does a printer enclosure benefit PLA printing? For PLA, an enclosure’s purpose is not to create a hot chamber, but a stable, draft-free microclimate. This prevents ambient air currents from causing uneven cooling, which is a primary driver of warping.

- Q5: What should I look for in a PLA printing supplier? Look for partners who calibrate their beds for dimensional repeatability, validate Tg response per material batch, and provide failure-mode-based optimization, especially for large-scale or OEM prototype production.

Conclusion: Elevating Temperature Control from Guesswork to Engineering

Mastering PLA bed temperature is not about finding a single magic number; it is about implementing a dynamic thermal management system based on an understanding of material science.

By treating failures as predictable outcomes of thermal mismanagement, troubleshooting becomes a logical process of calibration. This engineering-led approach, central to the philosophy at YISHANG, ensures that you can transform a digital model into a physical object with industrial-grade precision and repeatability.

For projects that demand this level of process control and reliability—especially in applications involving functional brackets, electronic test mounts, or temporary fixtures for sheet-metal—our team is ready to assist. We serve global OEM and wholesale partners seeking batch-level reliability and repeatable prototyping results. Feel free to send your inquiry today.