In the world of industrial automation and electrical engineering, project success hinges on reliability, efficiency, and adherence to standards. Before any PLC executes a command, a foundational decision has been made: the choice of the mounting system. To the professional system integrator, panel builder, or procurement manager, the DIN rail is the backbone that ensures project integrity, accelerates assembly, and guarantees long-term performance.

So, what is a DIN rail used for in industrial systems? At its core, a DIN rail is a globally standardized metal rail used as a universal mounting platform for a vast array of electrical and industrial control components inside equipment racks and control cabinets. Its primary purpose is mechanical support. While it is not meant to be used as a busbar for conducting current, its role in a system’s grounding scheme is critical—and often overlooked.

The true power of the DIN rail lies in the profound efficiency of its global standardization. It represents a paradigm shift from bespoke panel building to a modular, safe, and hyper-efficient ecosystem. This definitive guide is written for the professional, decoding the types of DIN rails, their material science, and installation best practices to ensure your projects are built on a foundation of quality and expertise.

DIN Rail History & Standardization: The Origin Story

The history of the DIN rail is a compelling story of engineering foresight. Before its invention, there were no standards for electrical panel development. Early control panels were a chaotic assembly of mismatched components, making them difficult to maintain and often unsafe. This inefficiency was the catalyst for change.

The origin of this technology can be traced to 1928 in Germany. An electrical utility, Rheinisch-Westfälisches Elektrizitätswerk company, collaborated with Phönix Elektrizitätsgesellschaft to solve the terminal block issue. Driven by a German ethos of Ordnung muss sein! (“There must be order!”), they sought a modular solution.

The initial designs used fragile porcelain, but this quickly evolved into a metal rail with an asymmetrical cross-section known as the G-profile. This was a masterstroke of practical design. Its unique shape not only provided a secure connection but also physically prevented components from being installed backward—a simple way to mitigate critical installation errors.

The success of this rail led to its rapid adoption. To ensure true interoperability, the Deutsche Institut für Normung (German Institute for Standardization) formalized the specifications in the 1950s, giving the “DIN rail” its name. This standard was eventually adopted by the International Electrotechnical Commission (IEC), resulting in the cornerstone IEC 60715 standard that governs modern DIN rails worldwide.

DIN Rail Types and Materials: Selection Guide

For the wholesale purchaser or system integrator, selecting the right DIN rail is a critical decision that directly impacts project outcomes. The choice of profile and material affects the stability, longevity, and safety of the entire control system. This is the foundation upon which mission-critical automation is built.

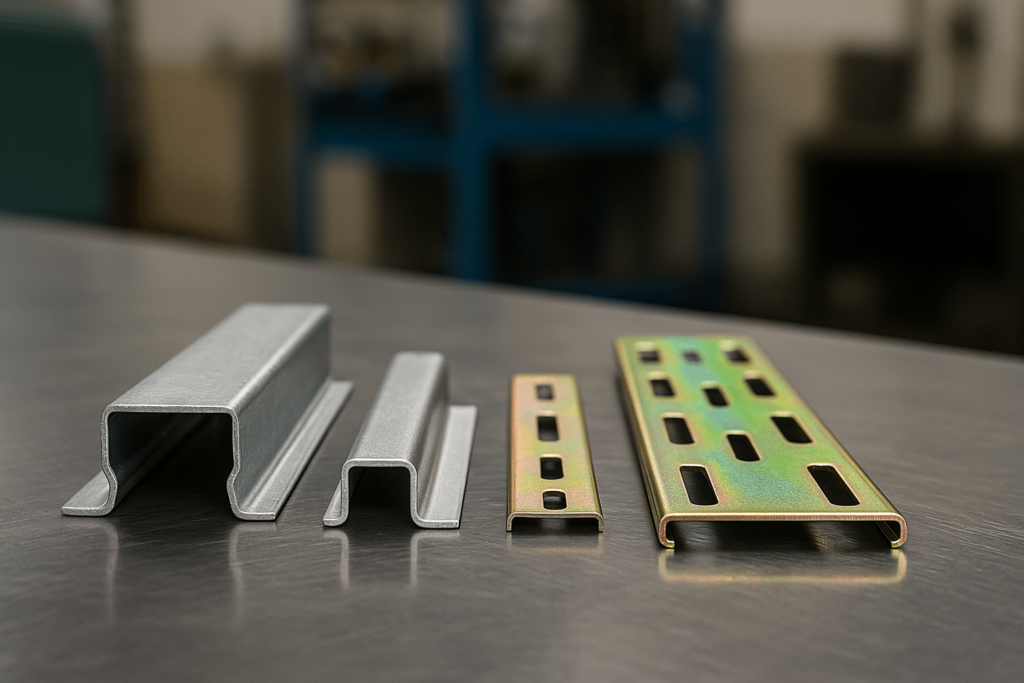

The Four Main Profiles, Precisely Positioned

The DIN rail system has evolved into a family of profiles, each tailored to specific load and space requirements.

- The “Workhorse” (TS35 “Top Hat”): This is the undisputed industry standard. The top hat rail is defined by its 35mm width and is the most versatile profile for mounting everything from circuit breakers to PLCs. It comes in a standard 7.5mm depth and a 15mm “deep hat” version, which offers greater rigidity for heavier components like large power supplies.

- The “Space Magician” (TS15 “Miniature”): The mini top hat rail is a scaled-down 15mm wide version. It is the ideal solution for applications where space is at an absolute premium, such as in a compact junction box or for mounting smaller components like miniature relays.

- The “Heavy-Lifter” (G-Section / TS32): The direct descendant of the original design, the G-rail features a 32mm wide, asymmetrical “G” shape. This profile is specifically designed to provide more support for large, heavy components like transformers and high-wattage power supplies.

- The “Legacy” (C-Section): The C-section rail is a legacy profile, now less common in new designs but still encountered in older installations. It was historically used for its perceived strength in supporting heavier components.

The Science of Materials: A Decision Framework for Purchasers

The material composition of a DIN rail you specify is a critical factor in its long-term performance and reliability.

- Standard Duty (Zinc-Plated Steel): The most common and cost-effective material is cold-rolled carbon steel sheet with a zinc-plated and chromated surface finish. This provides excellent strength for a standard steel enclosure and is the default choice for most indoor control cabinets.

- Harsh Environments (Stainless Steel): For applications in corrosive environments, such as food processing, marine, or outdoor installations, a stainless steel enclosure demands a stainless steel rail (like V2A/AISI 304). It offers exceptional resistance to rust and chemical attack, ensuring system longevity.

- Lightweight Needs (Aluminum): When weight is a primary concern, an aluminum enclosure is best paired with an aluminum rail. They are significantly lighter and offer good natural corrosion resistance, though with lower mechanical strength.

- Specialty Grounding (Copper): Copper is a specialty material used when the DIN rail itself must function as a high-conductivity chassis ground or Protective Earth (PE) conductor.

DIN Rail Buyer’s Checklist: How to Choose the Right Type

Selecting the correct DIN rail for your application involves more than just matching dimensions. Below is a professional checklist designed for procurement managers, engineers, and system integrators sourcing for industrial control panels, solar combiner boxes, or automation enclosures:

✔️ 1. Match the Profile to the Load Type

- TS35 Top Hat → General purpose; default for most PLCs, relays, and circuit breakers

- G-Section (TS32) → Heavier devices like power supplies or contactors

- TS15 Miniature → Limited space or miniature relay mounting

✔️ 2. Evaluate the Environment

- Indoor cabinet, low humidity → Zinc-plated carbon steel

- Marine, food processing, or corrosive atmosphere → Stainless steel (AISI 304)

- Mobile installations or lightweight enclosures → Aluminum DIN rail

- Need for built-in grounding → Use copper rails with verified PE continuity

✔️ 3. Verify Mounting Compatibility

- Always confirm DIN rail height and base compatibility with enclosure design (especially in compact cabinets)

- For existing legacy systems, ensure profile matches older components (e.g., C-section)

✔️ 4. Plan for Expansion & Maintenance

- Choose deeper TS35 (15mm) rails if future additions are likely

- Opt for standard profiles to simplify sourcing spare parts globally

✔️ 5. Check Certification Needs

- For critical industries (aerospace, medical, telecom), ensure material certifications align with your project’s QA standards (e.g., RoHS, ISO 9001)

DIN Rail Installation: Best Practices & Common Mistakes

Properly implementing a DIN rail system is where true craftsmanship and expertise are demonstrated. For the professional installer, a minor oversight can lead to significant electrical failure down the line.

Cutting the Rail: The Right Tool for a Clean Finish

The method used to cut the rail has a significant impact on the quality and safety of the final assembly. While manual methods like a hacksaw or Dremel tool can be used for one-off field modifications, they invariably leave sharp edges that require extensive finishing work.

For production environments, a specialized bench-top DIN rail cutter is the superior tool. These devices shear the rail cleanly and precisely, without creating burrs or deforming the profile. This saves significant time and produces a safer, more professional result.

The Non-Negotiable Step: Deburring

This step is absolutely critical after any manual cutting process. The sharp edges, known as burrs, must be smoothed with a file or belt sander.

Failure to do so creates two major risks. First, it is a significant safety hazard for installers. Second, these sharp edges can chafe and slice through wire insulation over time due to ambient vibration, creating a risk of a catastrophic short circuit.

Grounding: The Most Critical & Overlooked Detail

A conductive DIN rail can play a crucial role in the system’s Protective Earth (PE) or grounding system. However, this function is not automatic; it must be implemented correctly to be effective.

The most reliable method involves using specially designed grounding terminal blocks. These blocks, typically colored green and yellow, feature a conductive metal foot that clamps directly onto the rail, creating a secure electrical bond.

For the grounding path to be effective, there must be a continuous, low-resistance metal-to-metal contact. If the electrical enclosure backplate is painted, the paint must be scraped away at the mounting points. Failure to do so will leave the rail electrically isolated, creating a serious safety hazard. After installation, verify the ground path integrity with a multimeter; the resistance should be as close to 0 ohms as possible.

Applications of DIN Rails Across Industries

The versatility of the DIN rail system has led to its adoption in a multitude of sectors. For procurement managers, understanding these applications is key to sourcing the right components.

The Heart of Green Energy

In the renewable energy sector, DIN rails are foundational components. Solar power systems use them extensively inside PV (photovoltaic) combiner boxes to mount DC circuit breakers, fuses, and surge protection devices. Wind turbines rely on DIN rails to secure the complex PLCs and monitoring equipment that govern turbine operations.

The Nervous System of Smart Buildings

In the realm of smart buildings, DIN rails provide the mounting platform for the intelligence that manages a facility. Within HVAC control panels and lighting control systems, they securely hold thermostats, timers, controllers, and DALI/KNX modules.

The Backbone of IoT and Networking

In telecommunications and data centers, DIN rails provide a compact way to mount components like industrial Ethernet switches, routers, and IoT gateways. They form the physical backbone of the Industrial Internet of Things (IIoT).

DIN Rails in Industry 4.0 and Smart Components

DIN rail installation is not just about mounting hardware; it’s a bridge to the digital transformation of industrial systems.

The DIN rail standard has proven remarkably enduring. Its future relevance is secured by its ability to host the next generation of intelligent, connected components that are defining Industry 4.0.

A new generation of smart components—including IoT gateways, edge computers, and advanced sensors—is being designed in the DIN-mountable form factor. By mounting these devices directly alongside traditional control components, system integrators can seamlessly bridge the gap between operational technology (OT) and enterprise IT infrastructure.

This integration is a key enabler of concepts like predictive maintenance. By analyzing performance data from rail-mounted sensors, AI algorithms can predict potential component failures before they occur, drastically reducing unplanned downtime—one of the largest hidden costs in manufacturing.

Frequently Asked Questions (FAQ)

Q1: What is the standard size of a DIN rail?

A: The most common size is 35mm wide (TS35), as defined in IEC 60715, used in most control panels and enclosures.

Q2: Can a DIN rail be used for grounding?

A: Yes. Conductive DIN rails can serve as a grounding path if installed using grounding terminal blocks and verified for metal-to-metal contact.

Q3: What materials are DIN rails made from?

A: They are typically made from zinc-plated steel, stainless steel, aluminum, or copper—each suited for different environmental and load needs.

Q4: Which DIN rail is best for compact electrical enclosures?

A: TS15 miniature DIN rails are ideal for space-constrained applications such as junction boxes or embedded control systems.

Q5: Does YISHANG offer DIN rail OEM manufacturing?

A: Yes. YISHANG provides RoHS- and ISO 9001-certified DIN rail mounting components with global OEM/ODM services.

Conclusion: The Enduring Value of a Simple Standard

The DIN rail’s evolution highlights the power of international standardization. From a simple solution to bring order to electrical panels, it has grown into a foundational, global platform. For the wholesale purchaser, it is a crucial component that plays an important role in ensuring project efficiency, safety, and profitability.

Its core benefits—modularity, cost-effectiveness, and reliability—are more relevant today than ever before. As technology advances, the DIN rail continues to provide the stable, physical backbone required for our modern world.

With over 26 years of custom metal manufacturing experience, YISHANG supports global industrial clients with RoHS- and ISO 9001-certified DIN rail mounting products. 📩 Ready to streamline your control cabinet builds? Contact YISHANG today for ISO 9001-certified DIN rail components, expert OEM support, and fast global delivery.