Introduction: The Most Important Component You’re Overlooking

On an offshore oil rig, battered by corrosive salt spray, a vital safety instruction on a stainless steel nameplate remains perfectly legible years into service. This small component is not a decorative accessory; it is a mission-critical element responsible for safety, regulatory compliance, and brand reputation.

For engineers and procurement managers sourcing in bulk, treating the nameplate as an afterthought is a costly mistake. A failed tag can lead to illegible warnings, compliance violations, and a tarnished brand image—triggering warranty claims, operational disruption, and expensive service interventions.

This guide serves as a strategic procurement framework for specifying, designing, and sourcing custom stainless steel nameplates that outlast the products they identify. It offers technical insights for OEM and industrial buyers to make informed sourcing decisions that protect assets, enhance traceability, and reinforce a manufacturer’s reputation for long-term quality. Whether you’re sourcing marine-grade stainless plates, industrial logo nameplates, or UID-compliant tags, this article is your reference.

Section 1: The Silent Ambassador — Why Your Nameplate is a Critical Business Asset

For a professional buyer, every component must justify its cost and contribute to product reliability and downstream service efficiency. The nameplate is no exception. Investing in a high-grade stainless steel nameplate is a strategic move that delivers long-term returns through risk reduction, branding continuity, and operational resilience.

Beyond Durability — The Hidden ROI of Stainless Steel Nameplates

When evaluating nameplate options, a per-unit cost comparison can be dangerously misleading. The correct lens is Total Cost of Ownership (TCO). While a plastic tag or low-grade aluminum plate may appear more budget-friendly at first glance, they degrade quickly under UV exposure or chemical splash—leading to frequent replacements, extra labor, and unplanned downtime.

Aluminum alloys, while lightweight, generally lack the chemical and abrasion resistance of stainless steel, making them a risk in high-value or corrosive environments. A custom stainless steel nameplate from a trusted industrial manufacturer like YISHANG becomes a one-time investment in longevity and performance.

Its resistance to physical wear, solvents, and outdoor exposure ensures critical information remains intact. This durability lowers lifecycle costs and increases confidence in your component sourcing decisions—especially when purchasing OEM metal tags in bulk.

First Impressions are Permanent — The Psychology of a Quality Mark

Nameplates influence how equipment is perceived at every touchpoint in the supply chain. A flimsy or corroded tag projects carelessness and can drive warranty claims and credibility loss—liabilities the distributor or OEM may absorb.

In contrast, a robust, clearly etched stainless steel nameplate signals professionalism and permanence. For heavy-duty machinery, industrial electronics, or consumer-facing premium goods, the nameplate reinforces your company’s commitment to detail, traceability, and long-term reliability. This is particularly vital in industries that rely on traceable ID tags for machinery compliance.

The Non-Negotiable — Ensuring Compliance and Traceability

In regulated industries such as aerospace, medical devices, or food processing equipment, permanent nameplate identification is not optional—it is mandatory. Standards like MIL-STD-130 or FDA marking requirements dictate serialized traceability on components.

Stainless steel excels here by supporting precise, machine-readable formats like 2D Data Matrix codes and UID barcodes. These allow traceable, automated inventory control across multi-country production and field operations—minimizing compliance risk and downtime. OEM buyers often require UID-compliant nameplates to satisfy government contract regulations.

Section 2: The Blueprint — Specifying Your Perfect Nameplate, Step-by-Step

Designing the correct nameplate involves careful trade-offs in materials, marking technologies, finishes, and mounting solutions. Each decision affects performance, lead time, and cost per unit. The following steps offer a buyer-focused technical checklist.

The Foundation — Choosing Stainless Steel Grades for Custom Nameplates

Material selection is the first—and often most critical—decision. In stainless nameplates, austenitic Grades 304 and 316 are dominant choices for their corrosion resistance and machinability.

- Grade 304: A general-purpose alloy with good corrosion resistance in non-aggressive settings. Suitable for indoor or clean environments.

- Grade 316: Contains 2–3% molybdenum, significantly improving resistance to chlorides. Essential for marine, offshore, or chemical-heavy environments.

Though 316 is 40–75% more expensive than 304, it prevents costly failures and reorders in environments where 304 cannot survive. For buyers needing marine-grade nameplates or chemical equipment tags, 316 is the standard.

| Feature | Grade 304 Stainless Steel | Grade 316 Stainless Steel |

|---|---|---|

| Composition | ~18% Cr, ~8% Ni | ~16–18% Cr, ~10% Ni, 2–3% Mo |

| Corrosion Resistance | Effective in mild environments; vulnerable to chloride pitting | Excellent for salt, acids, marine and chemical exposures |

| Temperature Resistance | Up to 860°C | Up to 843°C |

| Tensile Strength | ~215 MPa | ~290 MPa |

| Hardness (HRB) | ~70 | ~79–80 |

| Cost | More budget-friendly baseline | Premium due to molybdenum and nickel content |

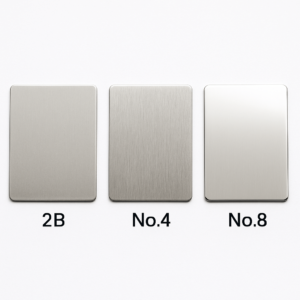

The Finish — Surface Options for Industrial and Decorative Nameplates

Surface finishes impact both appearance and durability. Consider environment, branding needs, and readability when specifying a finish:

- 2B Matte: Low-glare industrial finish. Best for utility-focused, non-visible surfaces.

- No. 4 Brushed: Popular satin finish with directional grain. Balances appearance and readability.

- No. 8 Mirror: Highly polished, premium-grade appearance. Often used in consumer-facing or architectural nameplates.

If you’re sourcing brushed metal serial plates for equipment labeling, No. 4 is often the industry default.

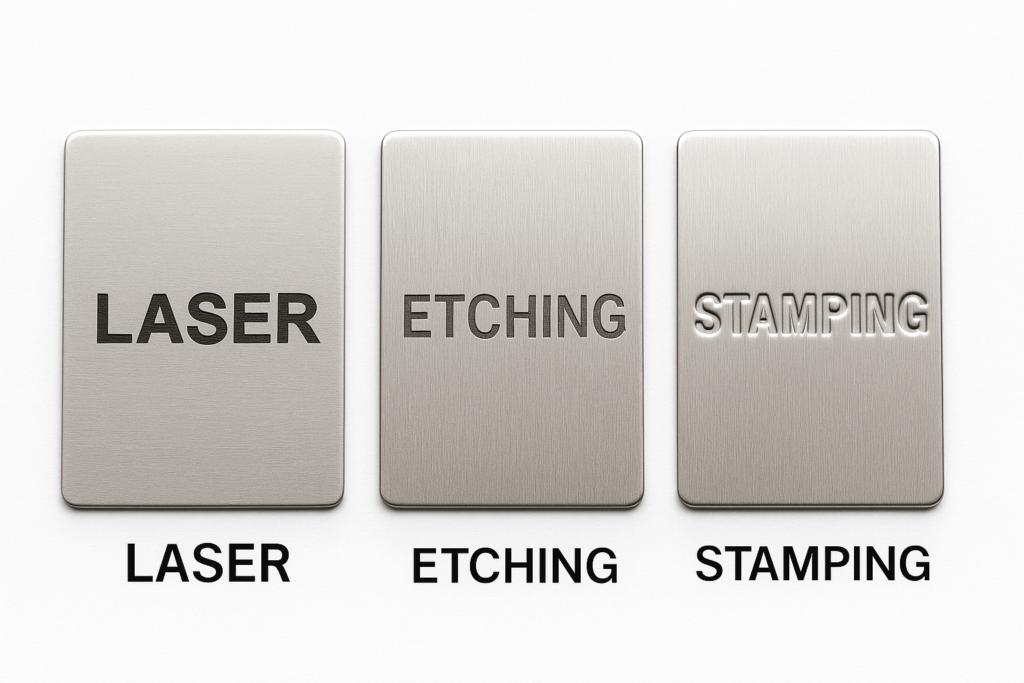

Nameplate Marking Methods — Laser, Etching & Stamping

Your marking method must withstand the field environment and match your product’s lifecycle:

- Laser Engraving & Chemical Etching: Ideal for high-detail, permanent data (serials, UIDs, compliance). Superior for outdoor or industrial use.

- Stamping & Embossing: Best for high-volume, standardized data. Raised or recessed text remains readable even with surface wear.

- Screen Printing: Allows for multicolor graphics but has lower resistance. Best reserved for decorative indoor uses.

If you’re sourcing laser-etched nameplates for serialized equipment tracking, be sure to confirm barcode scannability under field conditions.

Mounting Options for Stainless Steel Nameplates

Mounting style affects both usability and lifespan. It should match surface type, access, vibration level, and visibility requirements:

- Adhesive Backing: Clean, efficient, and drill-free. Industrial-grade adhesives like 3M™ VHB™ work well for flat, smooth surfaces.

- Mechanical Fasteners: Screws or rivets ensure permanence, especially for outdoor, high-vibration, or heavy-load applications such as aerospace or equipment panels.

Industrial buyers seeking permanent attachment often prefer riveted metal ID plates for equipment in vibration-heavy environments.

Section 3: Industrial Uses of Stainless Steel Nameplates in Harsh Environments

Stainless steel nameplates are deployed across industries where performance and accountability intersect. Below are common application environments:

- Marine & Offshore: Nameplates on ship engines or docks face high salinity and constant exposure. Grade 316 + etched or embossed markings are a must.

- Aerospace & Defense: Require riveted stainless plates with laser-engraved UID codes. Must meet MIL-STD-130.

- Medical & Food Processing: Must withstand sterilization and cleaning cycles. 316L stainless and smooth finishes align with HACCP and FDA requirements.

- Architectural & Luxury Branding: Premium products often use No. 8 mirror finishes for logo plaques and decorative accents that double as permanent branding.

Section 4: How to Source Custom Stainless Steel Nameplates in Bulk

Beyond technical specs, sourcing success comes from asking the right questions and avoiding red flags early in the quoting process.

Decoding the Quote — 7 Must-Haves in Your RFQ

Ensure your RFQ or BOM includes the following for accurate, comparable quotes:

- Stainless steel grade (304 or 316)

- Plate thickness in mm or gauge

- Surface finish type (2B, No. 4, No. 8)

- Cut dimensions (height × width)

- Marking method (laser, etching, stamping)

- Mounting type (holes, adhesive, bracket)

- Vector artwork (.AI, .SVG, .EPS)

For bulk production orders, also request MOQ, lead time, and shipping method to avoid delays.

5 Red Flags to Watch in a Supplier

Evaluate potential suppliers carefully, especially when buying internationally:

- Lack of ISO 9001 or material traceability certification

- Poor communication or response time

- No capability for variable data marking

- No support for Design for Manufacturability (DFM)

- Refusal to provide sampling or prototype

B2B buyers looking for reliable stainless nameplate manufacturers should always verify past export experience and reference projects.

Don’t Skip the Prototype — Your Final Line of Defense

Prototyping ensures that final mass-produced nameplates meet dimensional tolerance, finish, and visibility requirements. It also validates mounting choices and reveals potential marking contrast issues under real lighting conditions.

Requesting a pre-production sample is essential for risk mitigation in large-scale B2B orders. This is especially important when sourcing custom metal ID plates with variable serial codes.

Section 5: Stainless Steel Nameplate FAQ

- What is the most durable marking method? Laser engraving, etching, and embossing are all extremely long-lasting for industrial applications.

- Can I print full-color logos? Yes, screen printing supports full-color but is best suited for indoor or low-abrasion settings.

- What file types do I need? Supply only vector artwork (.AI, .SVG, .EPS), with all fonts outlined.

- What thickness should I use? Light-duty: 0.5–0.8 mm (0.020–0.032″); industrial: 1.2 mm (0.050″) or more.

- How do I clean stainless plates? Use mild soap and water; no abrasive pads. Stainless naturally resists rust and oxidation.

Conclusion: Your Brand’s Permanent Mark of Quality

A custom stainless steel nameplate isn’t a finishing detail—it’s a core asset that protects brand equity, assures safety, and ensures traceability over years of service.

When properly designed and sourced, it becomes more than a label—it’s a permanent, high-impact signature of your manufacturing discipline.

Need a sourcing quote for your next bulk production? Contact YISHANG for OEM stainless steel nameplate solutions tailored to your industry.