Introduction: Beyond the Spec Sheet: The Real Cost of Titanium Fabrication Failures

As a procurement manager or buyer in a high-stakes industry, your role extends beyond sourcing parts; you are a guardian of the supply chain, quality, and the bottom line. When sourcing titanium components, the risks are magnified.

A single failed weld leads to more than a scrapped part—it can trigger catastrophic project delays, budget overruns, and damage to your company’s reputation for quality.

The hard truth is that standard, off-the-shelf welding equipment is fundamentally unequipped for the challenges of titanium, making it a high-risk procurement strategy.

This guide is written specifically for you. It moves beyond basic technical specifications to address your core concerns: risk mitigation, quality assurance, and long-term value. We will deconstruct why conventional approaches to titanium welding are a recipe for failure, demonstrate how custom titanium welder parts are the only reliable solution, and provide a robust framework for vetting suppliers. Our goal at YISHANG—a China-based ISO 9001-certified metal fabrication company with over 26 years of experience—is to equip you with the expert knowledge needed to make informed, strategic sourcing decisions that deliver not just a part, but a competitive advantage.

The Root of the Problem: Why Standard Welding Setups Are a Liability for Titanium

The titanium welding challenges are not minor technical hurdles; they are fundamental material science issues that create significant business risks. Relying on generic equipment is an approach that fails to account for the unique properties of titanium, leading to predictable and costly failures.

Understanding these root causes is critical for any procurement professional managing a titanium supply chain or evaluating a titanium parts supplier.

The Contamination Crisis: A Threat to Material Integrity

The primary adversary in any titanium welding project is atmospheric contamination. At temperatures above 500°F (260°C), titanium becomes hyper-reactive, aggressively absorbing oxygen and nitrogen.

This process, known as oxygen embrittlement, is devastating. It transforms a strong, ductile metal into a material as brittle as glass, prone to cracking under operational stress. Even microscopic levels of titanium weld contamination can compromise the entire component, rendering it useless.

For industries where failure is not an option, such as aerospace or medical devices, a contaminated weld represents an unacceptable risk to safety and performance.

The Heat Trap: The Driver of Distortion and Tool Failure

A second critical liability is titanium’s extremely poor thermal conductivity. Unlike steel, titanium acts as a thermal insulator, trapping intense heat directly in the weld zone.

This “heat trap” leads to two major production problems. First, it causes significant thermal expansion and subsequent warping, making it incredibly difficult to hold the tight tolerances required for complex assemblies. Parts that fall out of spec lead directly to rework, delays, and increased costs.

Second, this localized heat rapidly destroys machining tools, increasing tooling costs and creating another potential point of production delay.

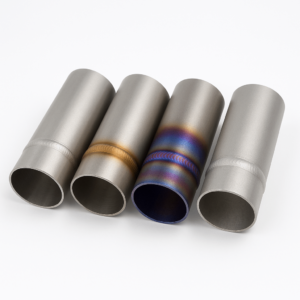

The Color Code of Failure: A Clear Indicator of a Flawed Process

Fortunately, titanium provides an unambiguous visual indicator of a compromised weld. The color of titanium after welding is a direct reflection of the level of atmospheric contamination.

For quality assurance, this titanium weld color chart is an essential and non-negotiable inspection tool used by any qualified titanium fabrication supplier.

| Weld Color | Quality Level & Business Implication |

|---|---|

| Bright, Shiny Silver | Excellent: The process is under control. The part meets spec for strength and corrosion resistance. |

| Light Straw | Acceptable: Minimal oxidation. Generally passes quality control for less critical applications. |

| Dark Straw / Brown | Reject: Significant contamination. The part is likely brittle and will not meet performance or lifespan requirements. |

| Purple / Blue | Reject: Severe contamination. The part has lost its ductility and corrosion resistance, posing a significant failure risk. |

| Gray / Chalky White | Catastrophic Failure: Extreme oxidation. The component is completely brittle and represents a total loss of material and labor. |

A procurement contract should specify the acceptable color range, as anything beyond a light straw indicates a fundamental flaw in the supplier’s process control.

The Inevitable Failure of Standard Nozzles & Fixtures

These challenges make it clear why generic, standard welding fixtures are inadequate. A standard TIG torch nozzle provides insufficient gas shielding for titanium, which requires protection across the entire heat-affected zone (HAZ) as it cools.

Similarly, standard clamps cannot provide the rigid, precision support needed to counteract thermal distortion. Relying on such equipment is a direct path to inconsistent quality, high scrap rates, and unreliable delivery schedules.

A buyer seeking custom titanium gas shielding solutions must ensure the supplier offers tailored TIG shielding components.

The Solution Set: Essential Custom Parts for a Reliable Titanium Supply Chain

To mitigate the risks of titanium fabrication, a controlled and repeatable process is essential. This is achieved through a suite of specialized, custom-designed tools.

For a procurement manager, specifying the use of these essential welder parts for titanium is a key step in ensuring a supplier can deliver consistent quality.

Custom Jigs & Fixtures: The Foundation of Precision and Repeatability

Custom welding jigs and fixtures are the bedrock of any professional titanium welding operation. Unlike generic clamps, these tools are precision-machined or 3D-printed to perfectly match the geometry of a specific component.

Their primary business function is to guarantee precision alignment and repeatability, part after part. By rigidly holding the component, they prevent the thermal warping that leads to out-of-spec parts and costly rework.

Advanced fixtures also incorporate integrated gas purging channels, a critical feature that delivers inert gas to the backside of the weld, ensuring 100% protection and full joint integrity.

When sourcing a titanium purge fixture supplier, verify that their fixturing supports both alignment and shielding functions.

Trailing Shields: A Strongly Recommended Tool for Quality Assurance

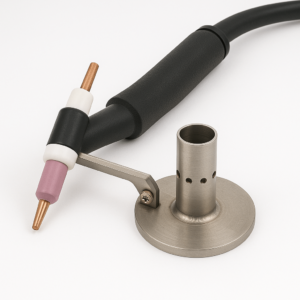

A TIG trailing shield is a custom device that attaches to the welding torch and provides a secondary blanket of inert gas over the weld as it cools. This is not an optional accessory; it is a strongly recommended quality assurance tool.

It protects the vulnerable, still-hot heat-affected zone from atmospheric contamination, preventing the post-weld embrittlement that is a leading cause of field failures. A supplier not using trailing shields for open-air titanium welding is not following recognized best practices.

Purge Dams & Backing Bars: Ensuring Full-Penetration Integrity

For any component requiring a full-penetration weld (e.g., pipes, pressure vessels), protecting the backside of the weld is mandatory. Purge dams and backing bars are used to create an inert atmosphere on the root side of the joint.

This weld backing purge is the only way to prevent the molten root from oxidizing, which would create a brittle, internal point of failure. Specifying that all full-penetration welds must be backed by an inert gas is a critical quality requirement.

Procurement contracts should define purge fixture requirements explicitly when evaluating a custom titanium welding fixture supplier.

Custom Gas Lenses & Nozzles: Optimizing the Shielding Environment

Finally, the quality of the shielding gas delivery itself is paramount. Custom TIG nozzles and, more importantly, a TIG gas lens, are essential.

A gas lens smooths the flow of argon, creating a stable, non-turbulent column of gas that provides superior protection against contamination. This stable shield is key to preventing porosity, a common defect that can compromise the structural integrity of the final component.

Buyers sourcing from a titanium contract manufacturer should confirm that custom gas lenses are available and integrated into their TIG process.

Manufacturing Capabilities: Vetting a Supplier’s Technology (3D Printing vs. CNC)

As a buyer, understanding a potential supplier’s manufacturing capabilities is crucial. For custom titanium parts, the primary methods are 3D printing (additive manufacturing) and CNC machining (subtractive manufacturing).

A capable supplier will not only have these technologies but will also understand when to apply each one for optimal results. Your evaluation of a supplier should include their rationale for choosing between 3D printing vs CNC machining titanium for your specific project.

When to Specify 3D Printing (Additive Manufacturing)

Additive manufacturing (DMLS/SLM) builds parts from titanium powder, layer by layer. Its key advantage is the ability to create parts with extreme geometric complexity.

- Strategic Advantage: This method is ideal for fixtures with complex internal channels for gas purging or cooling, or for creating lightweight lattice structures. This is where 3D printed titanium parts offer capabilities that are physically impossible with machining.

- Business Case: Additive manufacturing is highly cost-effective for rapid prototyping and low-volume production runs, as it requires no upfront tooling costs. Furthermore, it produces minimal material waste, a significant cost-saving factor when dealing with expensive titanium alloys.

When to Specify CNC Machining (Subtractive Manufacturing)

CNC machining is the gold standard for precision. It starts with a solid block of titanium and carves it into the final shape.

- Strategic Advantage: Machining titanium delivers unmatched precision, tight tolerances (often to ±0.005 mm), and a superior surface finish that requires little to no post-processing. This is critical for mating surfaces or features that require absolute accuracy.

- Business Case: For higher production volumes (typically 100+ units), CNC machining offers better economies of scale and a lower per-part cost once the initial setup is complete. It also guarantees the full, isotropic mechanical properties of the wrought source material, a critical requirement for many high-stress applications.

The Hybrid Approach: A Sign of an Advanced Supplier

The most advanced suppliers, like YISHANG, often employ a hybrid approach, using 3D printing to create a complex part and then using CNC machining to finish critical surfaces.

This hybrid manufacturing strategy combines the design freedom of additive with the precision of subtractive, delivering a superior final product. A supplier who can intelligently apply this approach demonstrates a high level of manufacturing expertise.

Risk Management: Avoiding the 5 Deadly Sins of Titanium Fabrication

A supplier’s experience is best measured by their ability to avoid common mistakes. These titanium fabrication mistakes are not just technical errors; they are process failures that result in defective products, wasted materials, and schedule disruptions.

A trustworthy supplier will have robust procedures in place to prevent these “deadly sins.”

- Using the Wrong Filler Rod: A simple but catastrophic error is using stainless steel filler on a titanium part. This creates a brittle joint that will fail. A capable shop will have strict material identification and handling protocols to prevent this.

- Inadequate Gas Shielding: This is the most common failure mode. It can be caused by leaks, incorrect flow rates causing turbulence, or insufficient post-weld shielding. An expert supplier will use gas lenses, trailing shields, and backing purges as standard practice.

- A “Dirty” Workspace: Cross-contamination from steel dust can destroy titanium’s corrosion resistance. A key indicator of a quality supplier is a dedicated, meticulously clean area for titanium work, with dedicated tools used only for titanium.

- Improper Machining Parameters: The rule for machining titanium is low speed, high feed rate. Ignoring this leads to work hardening of the material surface, making it nearly impossible to machine further and causing rapid tool failure.

- Ignoring the Backside of the Weld: Any full-penetration weld made without backside purging will be brittle at the root. This is a hidden defect that can lead to unexpected field failure. A quality-focused supplier will always ensure the root of the weld is protected.

Evidence of Performance: Real-World Case Studies

Claims of capability are meaningless without proof. When evaluating a supplier, ask for specific titanium welding case studies that demonstrate their ability to solve real-world problems and deliver measurable business value.

- Aerospace Case Study: In a project with aerospace leader Leonardo, traditional riveting was replaced with a custom laser welding process for titanium firewalls. The solution required highly specialized fixtures to manage heat and prevent distortion. The result was a projected 30% reduction in assembly time and a 20% overall cost saving, demonstrating a direct impact on production efficiency and profitability.

- Medical Device Case Study: A manufacturer needed to join delicate titanium wires to stainless steel housings. A custom micro-welding solution, dependent on a precision-engineered fixture, was developed. This process was 25–50% faster than laser welding, created a minimal heat-affected zone to preserve material integrity, and produced a stronger, filler-free bond that met stringent FDA requirements.

- Automotive Case Study: A major manufacturer facing a skilled labor shortage and high rework rates implemented a custom automated TIG welding cell. The critical component was the bespoke fixture, which ensured perfect, repeatable part positioning for the robot. This solution eliminated inconsistencies and delivered a remarkable 300% return on investment (ROI).

The Business Case: Calculating the True ROI of Custom Welding Fixtures

The procurement of custom welding fixtures should be viewed as a capital investment, not an operational expense. A proper ROI of custom welding fixtures analysis reveals their true value by looking beyond the initial purchase price and focusing on three key areas of return.

- Cost of Failure Reduction: Quantify the total cost of a single scrapped titanium part. This includes not just the high cost of the material, but also the accumulated labor hours and machine time. By drastically reducing scrap and rework rates, custom fixtures provide a direct and significant cost saving.

- Productivity and Throughput Gains: Custom fixtures are designed for efficiency. They dramatically reduce setup and changeover times, allowing for more parts to be produced per shift. In automated settings, they are the key enabler of “lights-out” manufacturing, maximizing the output of capital equipment.

- Labor Optimization: By automating simple, repetitive welds, custom fixtures allow you to reallocate your most skilled welders to more complex, higher-value tasks. This labor optimization ensures you are getting the maximum value from your skilled workforce.

A simple ROI calculation—Total Savings (Reduced Scrap + Increased Throughput) / Fixture Cost—often reveals a payback period that is surprisingly short, making it a compelling business decision.

The Supplier Vetting Checklist: 7 Red Flags to Spot Before Issuing a PO

Finally, how to choose a titanium parts supplier comes down to a rigorous vetting process. Use this checklist to identify capable partners and avoid those who pose a risk to your supply chain.

- Red Flag #1: No Industry-Specific Certifications. This is a deal-breaker. For aerospace, AS9100 certification is non-negotiable. For medical devices, it’s ISO 13485. These certifications are objective proof that a supplier has a robust and audited Quality Management System.

- Red Flag #2: They Cannot Offer Design for Manufacturability (DFM) Feedback. A true partner doesn’t just take orders; they collaborate. They should be able to analyze your designs and suggest modifications that could improve quality or reduce cost.

- Red Flag #3: Vague Answers on Process Controls. Ask for their documented procedures for material handling, cleanliness, and preventing contamination. A top-tier supplier will have clear, written protocols for every critical step.

- Red Flag #4: A Limited or Irrelevant Track Record. Ask for case studies and references for projects with similar materials, complexity, and industry standards to your own. A history of success with other major OEMs is a strong indicator of reliability.

- Red Flag #5: They Outsource Critical Processes. In-house control over machining, welding, and finishing (such as creating anodized titanium colors or a bead blast titanium finish) is highly preferable. A supplier that outsources key steps introduces more variables into your supply chain.

- Red Flag #6: Unwillingness to Produce a Prototype or First Article. You must be able to verify their quality firsthand before committing to a large production order. A refusal to produce a sample is a major red flag.

- Red Flag #7: Poor Communication and Responsiveness. A supplier who is slow or unclear during the quoting process will likely be a difficult partner during production. Clear, proactive communication is essential for success.

FAQ: Common Questions from Procurement Managers

❓ What is the ideal gas shielding setup for titanium welding?

A complete shielding setup includes a TIG gas lens, a trailing shield, and backing purge tools. This combination ensures protection across the entire weld zone and eliminates atmospheric contamination.

❓ Why is titanium welding so difficult compared to stainless steel?

Titanium is highly reactive to oxygen and nitrogen at elevated temperatures. Its low thermal conductivity also traps heat, causing distortion and tooling failure—making precision and shielding critical.

❓ How to choose a titanium welding fixture supplier in China?

Look for ISO 9001-certified manufacturers with in-house CNC machining and purge fixture experience. Prioritize those with case studies, tooling design support, and expertise in custom titanium parts.

Conclusion: The Future is Custom. Your Next Steps to a Secure Supply Chain.

For procurement professionals, mastering titanium fabrication is about mastering risk. Moving from standard parts to custom-engineered solutions is the single most impactful strategic shift you can make. It transforms the process from a high-risk gamble into a repeatable, controlled science.

By understanding the core business risks, specifying the right custom tools, and partnering with a truly qualified supplier who can demonstrate experience, expertise, and authority, you can secure your supply chain, ensure product quality, and unlock the full economic potential of this incredible material.

Ready to reduce scrap rates, avoid welding failures, and improve ROI on titanium parts? YISHANG is a China-based, ISO 9001–certified metal products manufacturer with 26+ years of experience in custom sheet metal fabrication, CNC machining, welding fixtures, and OEM/ODM parts. Contact YISHANG today to discuss your titanium welding fixture project, request a custom quote, or get a sample.