Introduction: From the Perfect CAD Model to a Costly Reality

Every great design begins as a perfect entity within a CAD model. But the moment it enters the physical world, it is subject to variation. This gap between digital perfection and manufacturing reality is where tolerance stacking lives—a silent factor that can lead to catastrophic failures and significant financial loss.

This guide is not just an academic exercise; it is a strategic manual for anyone involved in sourcing and manufacturing precision metal products. We will explore how to manage dimensional variation to prevent costly rework, product recalls, and functional failures, ensuring your supply chain delivers reliable, high-quality components.

For overseas sourcing managers, even a minor tolerance oversight can turn a container of precision parts into unusable scrap. Understanding tolerance stacking is essential not only for engineering accuracy but also for commercial success.

What Is Tolerance Stacking and Why It Matters

Tolerance stacking is the cumulative effect of multiple dimensional variations in an assembly, which can cause performance failure even when individual parts are within spec. For engineers, it directly affects functional performance; for overseas procurement professionals, it influences cost, scrap rate, and delivery timelines.

Engineering vs. Commercial Impact

An interference fit that works in CAD may not work in production due to stacking errors. This causes direct financial costs (rework, scrap, delays) and long-term brand risks (warranty claims, recalls). Poor tolerance analysis is not just an engineering oversight—it’s a commercial liability.

Business Risks of Ignoring Tolerance Analysis

- Scrap & Rework Costs: Assemblies built with out-of-spec cumulative tolerances can’t be salvaged easily.

- Line Downtime: Failed fits cause unexpected assembly line stoppage.

- Warranty Risks: Field failures are often traced back to tolerance accumulation.

How to Identify the Tolerance Stack Path

A tolerance stack path (or dimensional chain) traces all interdependent dimensions impacting a critical function. Identifying it is the first step toward control.

The Engineer’s Dilemma: Choosing Your Weapon—Certainty vs. Cost

Selecting a method for tolerance stack up analysis is not merely a technical choice; it is a strategic business decision that forces a direct trade-off between risk and cost. As a buyer, understanding which method your supplier uses for a given application provides deep insight into their approach to quality and cost management. The two primary methods, Worst-Case and Statistical Tolerance Analysis, represent two fundamentally different philosophies for managing variation.

The Worst-Case Method: The Path of Absolute Certainty

Worst-case tolerance analysis is the most traditional and conservative approach. Its core principle is simple and absolute: it calculates the maximum possible variation by assuming that every component in the stack path is manufactured at its most extreme, least favorable tolerance limit, all contributing in the same direction. This method answers the question: “If everything that can go wrong does go wrong, will this assembly still work?”

Because it accounts for the absolute limits, the worst-case method guarantees that 100% of assemblies built from in-spec components will function correctly. This makes it the required method for safety-critical applications, such as in the aerospace or medical device industries, where a single failure is catastrophic and 100% interchangeability is a contractual requirement. The trade-off for this guarantee, however, is significant.

Designing to the worst-case scenario often forces engineers to specify unnecessarily tighter tolerances. This level of precision may require advanced manufacturing processes like close tolerance precision machining, which dramatically increases manufacturing costs due to the need for more precise machinery, complex inspection processes, and higher scrap rates.

The Statistical (RSS) Method: The Path of Economic Reality

Statistical tolerance analysis, most commonly performed using the Root-Sum-Squared (RSS) method, operates on a fundamentally different and more pragmatic premise. It recognizes that in any large population of manufactured parts, dimensional variations will tend to follow a statistical distribution (often a normal or “bell curve” distribution), clustering around the nominal dimension. It is therefore extremely unlikely that all parts in an assembly will be at their maximum tolerance limit in the same direction at the same time.

Instead of arithmetically summing the tolerances, the RSS method calculates the total statistical tolerance by taking the square root of the sum of the squares of the individual component tolerances (TRSS = √(T1² + T2² + ⋯ + Tn²)). This approach allows engineers to significantly loosen individual component tolerances compared to the worst-case method, while still achieving a very high and predictable assembly yield.

This directly translates to lower manufacturing and inspection costs, making it the preferred method for high-volume production where a small, statistically predictable scrap rate is an acceptable trade-off for a large reduction in per-part cost. However, this economic advantage comes with critical assumptions. The validity of an RSS analysis hinges on the manufacturing processes being stable, centered, and following a normal distribution—a condition quantified by a high Process Capability Index (Cpk).

Tip for buyers: When sourcing precision parts, always ask whether your supplier uses RSS or worst-case tolerance analysis for high-precision assemblies. Their answer reveals a lot about their production confidence and pricing strategy.

From Theory to the Shop Floor: Two Real-World Metal Fabrication Case Studies

Case studies provide crucial context. For overseas procurement professionals working with CNC machining suppliers or custom metal fabricators, seeing how tolerance stacking plays out in real-world production helps evaluate supplier competency and project risk.

Case Study 1: The Simple Stack (Five Metal Disks)

To illustrate the dramatic practical difference between the methods, consider a simple assembly of five metal disks of varying thicknesses stacked together. Our goal is to determine the possible range for the total height of the stack.

Component Dimensions and Tolerances:

| Component Nominal Thickness (mm) Bilateral Tolerance (mm) | ||

|---|---|---|

| Disk 1 | 15 | ±0.5 |

| Disk 2 | 10 | ±0.1 |

| Disk 3 | 15 | ±0.2 |

| Disk 4 | 12 | ±0.3 |

| Disk 5 | 15 | ±0.4 |

Worst-Case Calculation:

- Nominal Stack Height: 15 + 10 + 15 + 12 + 15 = 67 mm

- Total Worst-Case Tolerance: ±(0.5 + 0.1 + 0.2 + 0.3 + 0.4) = ±1.5 mm

- Final Assembly Height Range: 67 ± 1.5 → 65.5 mm to 68.5 mm

RSS Calculation:

- TRSS = √(0.5² + 0.1² + 0.2² + 0.3² + 0.4²) = √(0.55) ≈ ±0.742 mm

- Final Assembly Height Range: 67 ± 0.742 → 66.258 mm to 67.742 mm

Procurement takeaway: If your product only requires a stack height tolerance of ±1 mm, using RSS can reduce component machining costs by allowing looser tolerances without sacrificing functional fit.

Case Study 2: The Complex 3D Fit (Axial Clearance in a Precision Gearbox)

Now, let’s move beyond a simple 1D stack and into a real-world challenge for a metal fabrication expert: controlling the axial clearance, or “end float,” of a shaft in a precision gearbox assembly.

The dimensional chain here is far more complex. It starts at a fixed face inside the gearbox housing, travels through the outer race of a bearing, across the bearing balls, through the inner race, along a shoulder on the shaft, across a spacer, through the next bearing, and finally to the opposing face of the housing.

This isn’t just a stack of lengths. We must consider how geometrical tolerances from CNC close tolerance machining contribute. The positional tolerance of the bearing bores in the housing and the perpendicularity of those bores to the housing faces directly impact shaft alignment.

Further complexity arises from material selection. A gearbox with an aluminum housing and a steel shaft will experience different rates of thermal expansion at operating temperature. This differential expansion must be calculated and included in the tolerance stack up analysis as another variable.

Buyer insight: When sourcing multi-material precision assemblies, request tolerance studies that include thermal drift, especially if aluminum housings are involved. Many suppliers omit this.

This real-world example illustrates how tolerance stack up analysis must move beyond simple math and include environmental factors and GD&T-based dimensional control.

Common Pitfalls in Tolerance Analysis: Don’t Fall for These Traps

Even seasoned engineers and buyers can fall into hidden traps when dealing with tolerance stack ups. Understanding where most designs go wrong is a key step in improving both manufacturability and yield.

Trap #1: Assuming Perfect Centering of Processes

Many engineers assume that all variations center perfectly around the nominal dimensions. In reality, manufacturing processes often show process drift or tool wear, causing asymmetrical distributions. This violates the key assumptions behind statistical methods and can result in underestimating the actual risk.

Tip for buyers: Always ask for process capability data (Cp/Cpk). A Cpk below 1.33 means your supplier’s process may not reliably support statistical tolerance assumptions.

Trap #2: Over-Tightening Tolerances Without Considering Cost

Specifying ultra-tight tolerances across all parts might seem like a fail-safe plan—but it leads to excessive manufacturing costs and extended lead times. A 0.01mm tolerance on a non-critical dimension wastes resources and drives up prices without adding value.

Procurement note: Align tolerance budgets with function. Request DFM (Design for Manufacturability) support from suppliers to identify where loosening tolerance saves cost.

Trap #3: Ignoring Geometric Tolerances (GD&T)

Focusing only on linear dimensions ignores the impact of geometric variation—such as angular misalignment, flatness, or perpendicularity. In reality, these geometric errors often contribute more to functional failure than linear variations.

Sourcing tip: Suppliers fluent in GD&T can often reduce part cost while improving consistency. Ask if your supplier offers GD&T-based design validation.

Tools That Help You Win: GD&T, Digital Twin, and Closed-Loop Feedback

Manufacturing is evolving fast. Smart buyers and engineers use tools that go beyond basic arithmetic to manage tolerance stacking.

GD&T (Geometric Dimensioning & Tolerancing)

This system defines not just how much a feature may vary, but how it can vary in orientation and position. It provides a far more realistic representation of how parts interact in 3D space. By applying datum reference frames, MMC (Maximum Material Condition), and true position tolerances, you can reduce uncertainty while maintaining manufacturability.

Supplier qualification tip: Manufacturers fluent in GD&T are far more likely to prevent tolerance stack issues during prototype-to-production transitions.

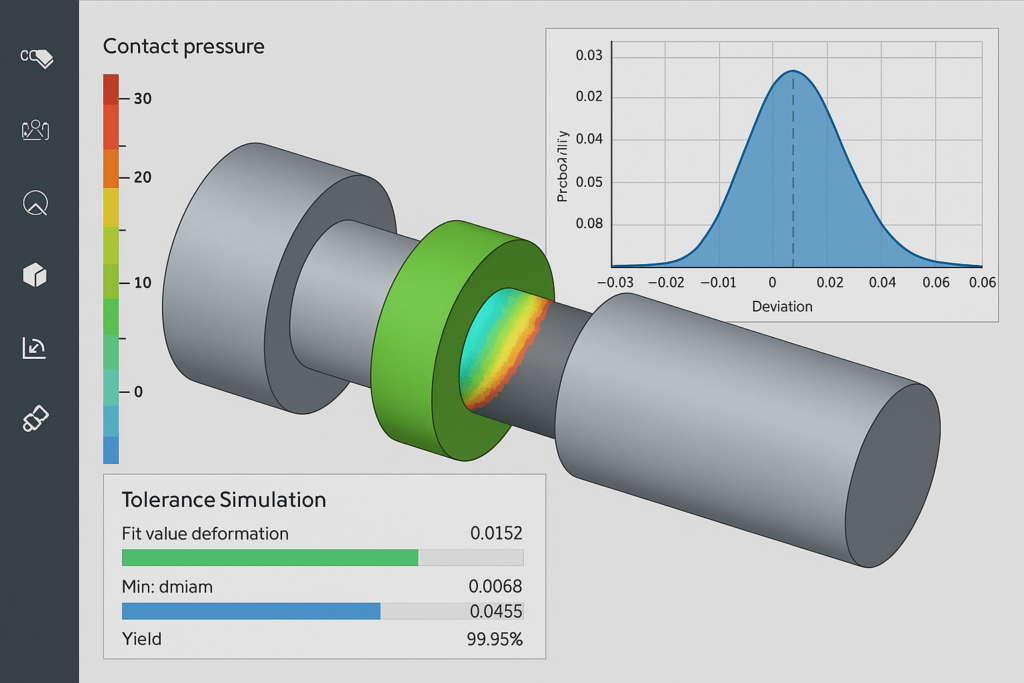

Digital Twin Analysis

Today’s advanced simulation tools allow manufacturers to create a “digital twin” of the full assembly. These tools simulate how variations from every part affect the functional fit of the final product. By running thousands of tolerance scenarios, engineers can statistically predict and optimize the assembly yield before a single part is made.

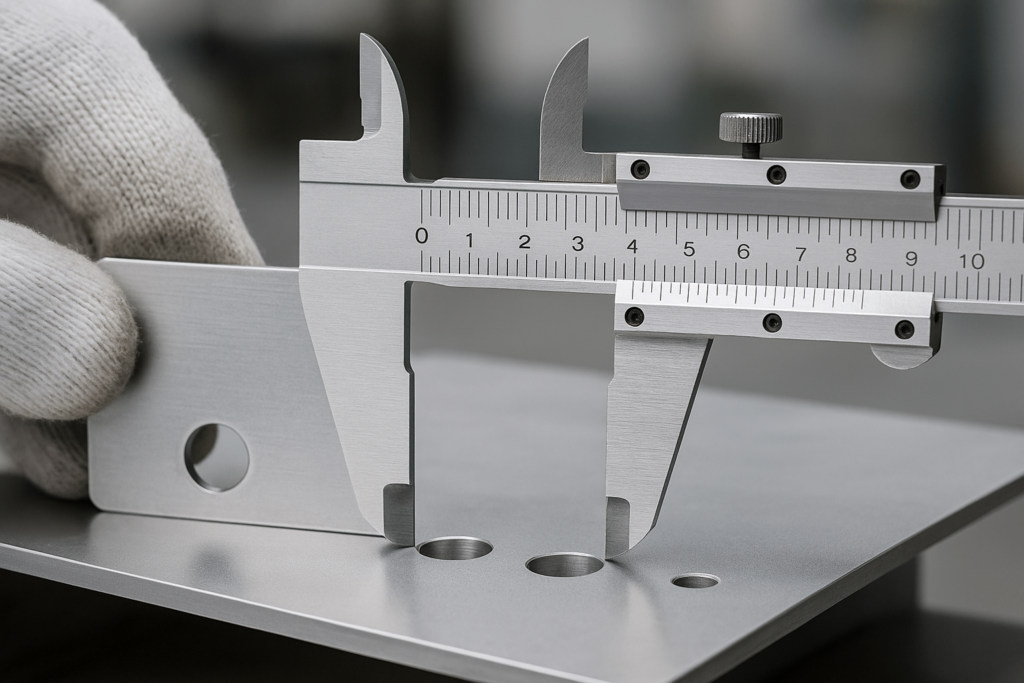

Closed-Loop Manufacturing

In a closed-loop process, real-time measurement data from production (e.g., from a CMM or laser scanner) is fed back into design systems to dynamically adjust machining parameters. This ensures the actual part conforms to the tolerance model—reducing rework, improving consistency, and increasing traceability.

B2B advantage: Closed-loop feedback is particularly useful when working with overseas metal suppliers. It provides documented traceability and remote confidence in production accuracy.

Final Thoughts: Tolerance Management Is Strategic Procurement

In today’s competitive global market, mastering tolerance stack up is not just an engineering necessity—it is a strategic procurement advantage.

When you understand how dimensional variation accumulates, you can make smarter sourcing decisions, reduce unnecessary cost, and avoid painful surprises in assembly. Whether you’re working with high-volume metal stamping, low-volume CNC prototypes, or complex sheet metal enclosures, proper tolerance analysis ensures reliability, reduces scrap, and improves time to market.

At Yishang, we support OEM and ODM clients worldwide in managing tolerance stack ups through:

- Professional GD&T interpretation & consulting

- Full-process CNC and sheet metal fabrication (cutting, welding, bending, surface treatment)

- Statistical quality control reports (Cpk, Cp) on request

- Tolerance-based DFM optimization and digital simulation

Did you know? Our tolerance audits helped one overseas client reduce scrap rates by 37% within two production runs—just by revising tolerance strategies during DFM.

📌 Ready to Stop Guessing and Start Controlling Your Tolerance Stack?

📞 Talk to our engineers today about your project’s tolerance chain challenges.

📩 Or send us your CAD files and receive a manufacturability analysis within 24 hours.