Introduction: A 10,000 Horsepower Engineering Decision

This article outlines the engineering rationale behind choosing aluminum over steel for high-output connecting rods.

In high-performance engine manufacturing, a critical engineering decision lies at the core of the world’s most powerful machines. Why do Top Fuel dragsters and Pro Mod engines rely on connecting rods made from aluminum? This challenges the common belief that steel is for strength and aluminum is for weight savings.

From an engineering and manufacturing standpoint, the reality is far more sophisticated. This document serves as a definitive technical briefing for professional engine builders and wholesale procurement managers.

We will move beyond marketing claims to explore the science, application, and critical manufacturing considerations behind high-performance connecting rods. This is the foundational knowledge required to make a sound engineering and supply chain decision.

The Fundamental Question: Why Choose Aluminum Over Steel?

The aluminum vs steel connecting rods debate is central to performance engine building. The choice is not about simple material strength but about managing violent dynamic forces within a high-output engine, with profound implications for reliability under extreme stress.

The Role of Steel: The OEM Standard

Forged steel rods are the standard for production vehicles due to their balance of strength, rigidity, and durability. For an engine under predictable loads, the high rigidity of a steel rod is an asset, ensuring stable power transfer.

However, in extreme horsepower applications, this steel rod rigidity becomes a liability. Under the instantaneous pressure spikes from boost or nitrous, a steel rod acts like a sledgehammer, transmitting the unmitigated shockwave to the bearings and crankshaft, risking catastrophic failure.

The Aluminum Advantage: More Than Just Weight Savings

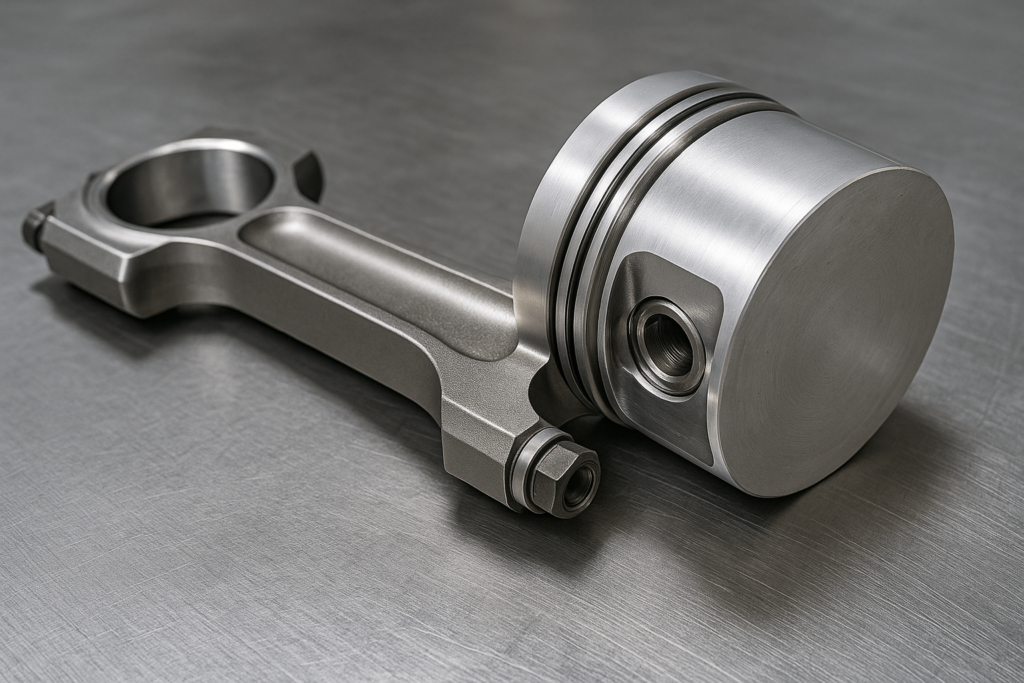

Lightweight connecting rods made from aluminum significantly reduce reciprocating mass, allowing an engine to rev faster and improving throttle response. But the true advantage lies in a property far more critical than weight.

The “Shock Absorber” Secret

The primary reason to use an aluminum rod shock absorber in a power-adder engine is its lower Modulus of Elasticity. In simple terms, aluminum is more elastic than steel; it can “give” or stretch minutely under extreme load and then return to its original state.

This inherent elasticity of aluminum allows it to cushion the violent impact of combustion. By extending the duration over which force is applied to the crankshaft, it transforms destructive shock into manageable load. This dynamic behavior protects the crankshaft and prevents rod bearing failure under the extreme cylinder pressure of today’s most powerful engines.

Durability Dilemma: How Long Do Aluminum Connecting Rods Last?

The question of how long do aluminum connecting rods last is often met with the misconception that they are “single-use” components. For a procurement manager, understanding the true operational lifespan is critical for advising clients and managing inventory. The aluminum connecting rod lifespan is a predictable, application-dependent engineering parameter.

Debunking the “Single-Use” Myth

The idea of discarding rods after a few passes is one of the most pervasive aluminum rod myths. The usable life is entirely dependent on the severity of the loads.

- Top Fuel/Pro Mod: In these classes, rods are a scheduled consumable, replaced after a handful of runs.

- Bracket Racing: In milder combinations, a set of aluminum rods can last for hundreds of passes.

- High-Performance Street/Strip: Many builders recommend proactive replacement after 10,000 to 15,000 miles.

The Science of Fatigue Life

Understanding the fatigue life of aluminum vs steel is key. The fatigue behavior of a material is shown on an S-N curve. Steel has an endurance limit; below a certain stress level, it can theoretically last forever.

Aluminum alloys do not possess an endurance limit. Their S-N curve slopes downward indefinitely, meaning every stress cycle consumes a fraction of the material’s finite fatigue life. This behavior is predictable and manageable through proper engineering. At YISHANG, our in-house aluminum fatigue testing process ensures rod integrity and lifespan under real-world loads.

Using Finite Element Analysis (FEA), we predict stress concentrations and calculate cycles to failure, ensuring the product meets the demands of its intended application.

Manufacturing Process Duel: Forged vs. Billet?

For a wholesale buyer, understanding the manufacturing process is crucial as it impacts consistency, cost, and customization capabilities. The forged vs billet aluminum connecting rods debate centers on this trade-off.

Forging: Strength in Alignment

The forging process uses a die and immense pressure to shape heated aluminum. This forces the metal’s internal grain flow to align with the part’s contours, resulting in superior fatigue resistance and impact strength. YISHANG’s custom forged aluminum parts division specializes in these applications.

The high initial tooling cost makes forging ideal for high-volume, standardized production runs, ensuring batch-to-batch consistency at a competitive price point.

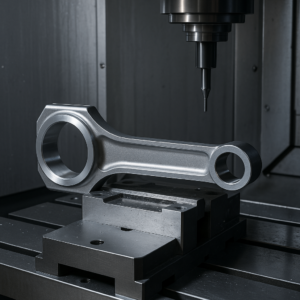

Billet: The Art of Precision and Customization

Billet aluminum rods are created by machining a rod from a solid block of aluminum using CNC machines. This subtractive process offers unparalleled design flexibility, perfect for custom billet aluminum rods and small-batch orders. Our CNC aluminum billet machining team ensures precision across tight-tolerance specs.

The trade-off is in the material grain structure, which is uniform but not aligned with the part’s shape. However, for custom applications, the precision of CNC machining is paramount.

The Verdict for Procurement

While forging offers a theoretical strength advantage, the raw material quality and design precision are often more critical. A billet rod from a premium, certified aluminum alloy can outperform a forged rod made from lesser material. YISHANG’s expertise in both processes allows us to recommend the optimal solution based on your volume and technical requirements.

Structural Design Showdown: I-Beam vs. H-Beam?

The I-beam vs H-beam connecting rods debate is a matter of applied physics. The choice of geometry is directly influenced by the material properties and the forces the component must endure.

I-Beam: The King of Compression

The I-beam’s “I” shape concentrates mass at the outer edges, making it inherently resistant to bending and buckling under high compression loads. This makes it the superior design for high-pressure applications like boosted engine rods, especially high strength aluminum rods for turbo engines.

Installation & Customization Masterclass: How to Install Aluminum Connecting Rods with Proper Clearances

Successfully installing aluminum connecting rods requires adherence to strict technical guidelines. Providing this information demonstrates our commitment to the end-user’s success, a key value-add for our wholesale partners.

Critical Clearances You Can’t Ignore

- Piston-to-Head Clearance: Aluminum’s higher thermal expansion and dynamic stretch require greater clearance. A typical

piston to head clearance for aluminum rodsis .060 to .080 inches, compared to .040 for steel. - Bearing and Side Clearances: A minimum

rod bearing clearance specof .0025 inches is mandatory to account for thermal expansion of the big end bore.

Torque vs. Stretch: The Professional’s Method

The rod bolt stretch vs torque method is the industry best practice. Measuring the physical elongation of the bolt provides a direct measurement of preload, ensuring the big end bore remains perfectly round under load. This is a critical quality control step.

| Bolt Type | Recommended Stretch | Torque (with 50W oil) |

|---|---|---|

| 3/8” ARP 2000 | .0058” – .0064” | 65 ft-lbs |

| 3/8” L19 | .0065” – .0070” | 75 ft-lbs |

| 7/16” ARP 2000 | .0055” – .0060” | 80 ft-lbs |

| 7/16” L19 | .0060” – .0068” | 90 ft-lbs |

| (Data from R&R Racing Products installation guide) |

Working with a Manufacturer: The YISHANG Process

When ordering custom connecting rods, a collaborative process is key. We work with our partners to define precise connecting rod dimensions based on the intended application. This level of customization and technical support is what separates a high-end component supplier from an off-the-shelf retailer.

Conclusion: It’s Not Just a Part, It’s an Engineering Decision

The selection of an aluminum connecting rod is a holistic engineering decision. Its primary function in high-stress environments is as a dynamic damper, absorbing shock loads that would otherwise destroy more rigid components.

Understanding its properties—from its manageable fatigue life to its specific material and design requirements—is key to unlocking reliable horsepower. As a metal parts supplier China, YISHANG provides the technical expertise and production capability to deliver components that meet the highest standards of quality and performance in RoHS-compliant and ISO 9001-certified facilities.

For technical specifications or to submit custom requirements, contact YISHANG’s engineering support team today.

Frequently Asked Questions (FAQ)

Q: Can I use aluminum connecting rods in a daily driver street car?

A: It is generally not recommended. Steel offers a near-infinite fatigue life required for high-mileage use, whereas aluminum’s finite fatigue life is better suited for racing and limited-use performance vehicles.

Q: Are aluminum rods stronger than steel rods?

A: In terms of raw material strength, no. However, in a high-horsepower engine, their ability to absorb shock allows them to survive applications where a rigid steel rod would fail or cause other components to fail.

Q: How much lighter are aluminum connecting rods?

A: They can be around 100–150 grams lighter than a comparable steel rod, which significantly reduces the mass of the rotating assembly and allows the engine to accelerate and rev more quickly.

Q: Do aluminum connecting rods stretch?

A: All connecting rods stretch under load. Modern aluminum alloys have minimized permanent stretch, but they do require more initial piston-to-head clearance (typically .060″–.080″) to account for thermal expansion and dynamic stretch at high RPM.