Introduction: Why Delrin Machining Projects Fail in the Real World

Delrin, or acetal homopolymer, is celebrated for its machinability, tensile strength, and dimensional stability. But in the real world of bulk procurement and global B2B supply chains, the gap between lab performance and mass production reliability becomes glaring. Failures arise not from material flaws, but from engineering decisions made without full awareness of Delrin’s behavior at volume.

This guide is tailored for procurement managers, product engineers, and B2B sourcing professionals. Instead of repeating datasheet metrics, we focus on how to design, source, and validate Delrin CNC components that truly perform under operational, logistical, and economic pressures.

Delrin’s Machinability: Advantages and Pitfalls at Scale

Delrin’s excellent machinability makes it a go-to for prototypes. But what’s ideal for one-off runs can introduce risk in high-volume production.

Prototype vs. Production Behavior

While initial samples may seem perfect, scale reveals challenges:

- Flat parts may warp during overseas transit or climate changes.

- Unannealed blanks retain stress, leading to post-assembly distortion.

- Geometrically asymmetric designs create internal torsion post-machining.

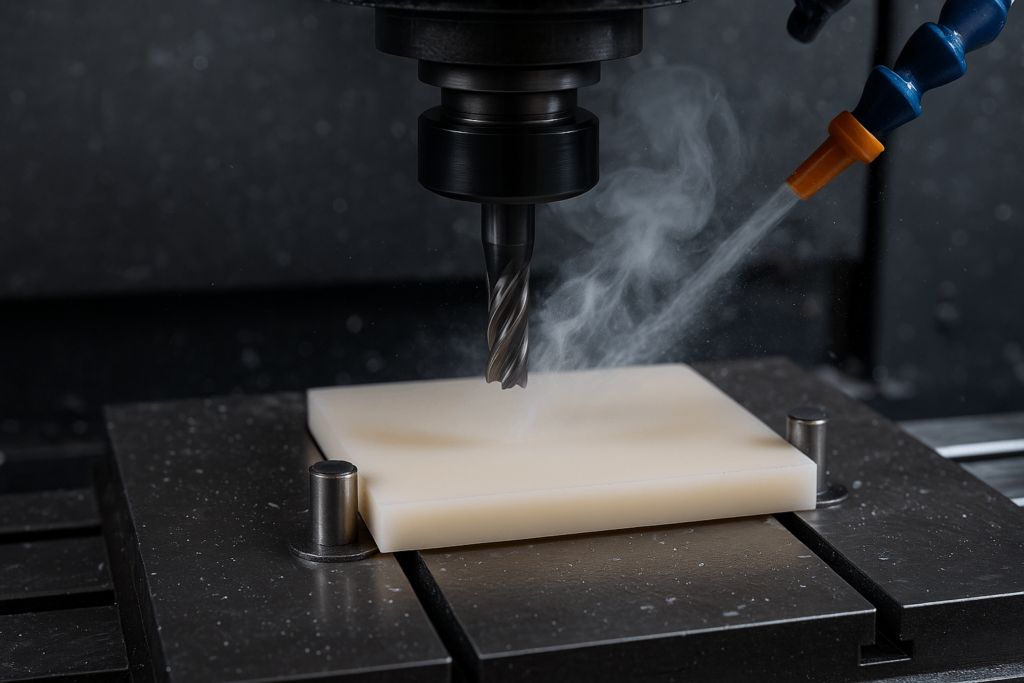

📌 Recommendation: Confirm with your vendor if mist cooling and thermal stress relief (annealing) are standard in their process. These aren’t add-ons—they’re essential for consistency.

Grade Selection: Matching Performance to Real-World Function

Not all Delrin is created equal. Grade selection directly affects durability, compliance, and even machining yield.

Common Grades and Their Best Uses

| Grade | Key Benefits | Typical Applications |

|---|---|---|

| Delrin 150 | Stiff, impact-resistant | Electrical covers, clamps, push-button housings |

| Delrin AF (PTFE) | Low friction, dry-running surfaces | Sliding panels, actuator guides, rotary bearings |

| FDA-Approved | Safe for food/med automation | Conveyor rollers, vending machine contact surfaces |

| UV/ESD Stabilized | Outdoor-ready, static dissipative | Solar battery enclosures, telecom distribution boxes |

🧾 Traceability Tip: Always require certification for grades intended for regulated industries.

Design Considerations: Getting Manufacturability Right

A successful Delrin part starts on the drawing board. Good design is more than geometry—it accounts for how plastic behaves during and after cutting.

Wall Thickness: Design for Stability

Very thin walls may bow or curl:

- Use 2.5–6 mm wall thickness for unsupported spans.

- Add ribs or bosses to reinforce covers, junction boxes, or modular panels.

Internal Radii: Mitigate Stress Cracking

Sharp corners concentrate stress. Best practices:

- Apply 0.75× wall thickness as minimum internal radius.

- Use smooth transitions between features to prevent material fatigue.

Tolerances: Know Where It Counts

Over-tolerancing increases scrap and cost:

- ±0.01 mm for moving/sliding features

- ±0.05–0.10 mm for structural areas

🎯 Pro Sourcing Tip: Mark tolerance-critical zones clearly on RFQs—vendors can’t guess what’s critical.

Supplier Capabilities: Validate Before You Commit

No matter how good your design, it will fail without the right execution. Here’s what separates dependable vendors from problematic ones.

Machining Setup: Tune for Delrin

- Carbide tools for sharpness retention

- Air or mist cooling to prevent moisture uptake

- Dry machining preferred for FDA-grade parts

Especially important for IP-rated boxes, meter covers, and automated module frames.

Residual Stress Management

Residual stress distorts parts post-machining:

- Apply rough–rest–finish strategy

- Post-process annealing at 160–170°C ensures dimensional stability

🧩 Confirm that your vendor includes these steps in their SOP.

Quality Control Protocols

Go beyond dimensional checks:

- Inspect for surface burrs under magnification

- Measure flatness and warp tolerance

- Apply sampling plans (e.g., 1 in every 25–50 units)

📦 Insist on non-stacking trays for thin parts—compression damages edges.

Real Mistakes and What They Teach

Learning from real-world sourcing failures saves time and budget.

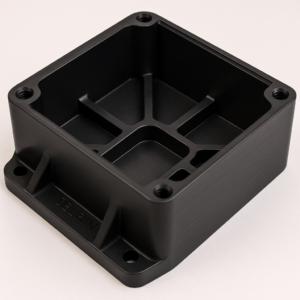

🔩 Case 1: Warped Junction Box Covers

- Issue: Transit-induced bending

- Resolution: Reinforced ribbing and hard-shell packaging

🍽 Case 2: FDA-Grade Residue Rejection

- Issue: Coolant left behind

- Resolution: Shift to dry-cutting and IPA wipe-down

🔌 Case 3: Insert Pullout in Control Modules

- Issue: Incorrect interference fits

- Resolution: Thermal model validation and tolerance redesign

📣 Include functional testing like torque, fit, or thermal load validation in your RFQ package.

Write a Better RFQ: The Procurement Advantage

A clear RFQ helps suppliers respond faster and manufacture more accurately.

RFQ Checklist for Delrin Parts

- Provide STEP + 2D PDF files with key tolerances marked

- Specify Delrin grade and functional purpose

- Mark fit zones (e.g., sliding, locking, sealing)

- Define QC expectations (surface, flatness, burrs)

- Describe packaging: tray, non-stack, anti-static, etc.

🔧 At YISHANG, our CNC engineering team checks RFQs for risk areas—avoiding scrap, delay, and misalignment.

Conclusion: From CAD to Container with Fewer Surprises

Delrin is highly capable—but only when treated as more than “just another plastic.”

To succeed in real B2B scenarios, buyers need alignment between material science, part design, and manufacturing strategy. That’s what ensures tolerance, function, and delivery timelines stay on track.

YISHANG brings 26+ years of metal and plastic CNC integration, helping procurement teams across electronics, solar, telecom, and automation scale smarter.

📩 Let’s get your next project done right—send your inquiry to YISHANG today.