Why 73% Uptime Is the Industry’s New Normal, and How the Right Enclosure Strategy Is the Only Way to Win

The electric vehicle market is expanding at an unprecedented rate. For wholesale purchasers and distributors, this presents a massive opportunity. However, a persistent and costly problem threatens to undermine profitability and damage brand reputation: charger reliability.

While network operators often claim uptimes of 95–98%, real-world data reveals a very different reality. A 2022 field study across 657 EV chargers showed only 72.5% were fully functional when tested in person. This isn’t just an inconvenience; for your business, it’s a direct threat to ROI.

Industry narratives often focus on network software or connectivity—but those issues are just part of the story. In many cases, the actual root cause lies within something more basic and overlooked: the EV charging station cabinet. Often deprioritized as a cost-saving item, the electrical enclosure is in fact the critical infrastructure that protects every vital internal component.

This guide is tailored for strategic B2B buyers. Rather than listing generic specs, we reframe the EV charger enclosure as a performance asset. You’ll find a structured, practical playbook for mitigating risk, optimizing Total Cost of Ownership (TCO), and creating procurement value through strategic materials, engineering, and supplier partnerships.

Diagnosis — Why Your Network Is Bleeding Money (And It’s Not the Reason You Think)

For distributors and large-scale purchasers, every failed charging session translates into lost revenue, warranty claims, and damage to your brand’s credibility. Understanding the true source of these failures is the first step toward building a more profitable and resilient business.

Fault Scene Recreation: A Single Millimeter, A Multi-Thousand-Dollar Liability

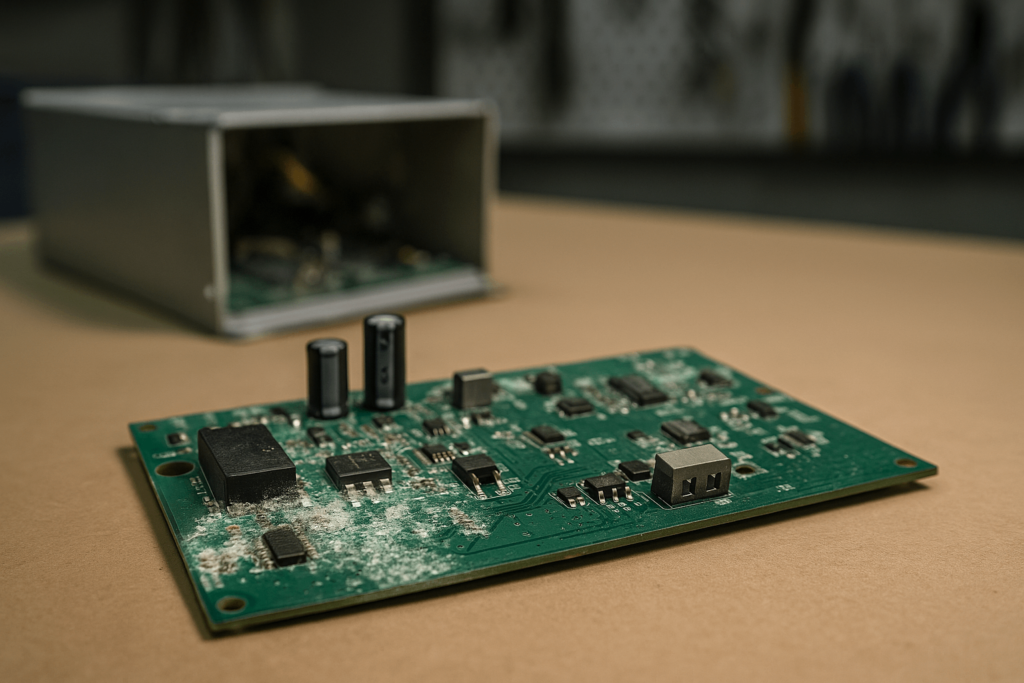

Imagine this scenario: a customer uses a charger from a batch you distributed. The screen is on, but it fails to initiate a charge. A technician is dispatched, and the cause is found to be a corroded circuit board due to moisture ingress.

This common EV charger failure didn’t start in the field—it began on the factory floor, where poor manufacturing precision led to a slightly warped cabinet door. That single millimeter of distortion broke the environmental seal, allowing humidity to compromise high-value electronics.

The result? A seemingly minor flaw becomes a multi-thousand-dollar problem, impacting not only maintenance costs but also end-user trust in your entire product lineup.

Piercing the “98% Uptime” Myth: A Costly Discrepancy

The gap between advertised and actual EV charger uptime introduces significant operational and reputational risk. While network diagnostics may report that a station is “online,” functional testing often says otherwise.

As mentioned earlier, studies confirm that real-world charger reliability often falls below 75%. For buyers, this discrepancy translates into recurring field interventions, warranty claims, and customer dissatisfaction—often due to issues stemming from the outdoor electrical enclosure.

The lesson? Overlooking enclosure quality during procurement leads to unexpected system failures and a weaker long-term ROI. A single failed DC fast charger can result in over $5,000 in lost revenue per month.

The Hidden Assassins of Your ROI

To protect your investment, you must understand the forces that relentlessly attack your assets. A well-engineered charging station cabinet is not just housing—it’s a frontline defense.

The Slow Death: Water, Dust, and Heat

Environmental stress is the leading cause of premature component failure. The primary countermeasure is achieving appropriate IP (Ingress Protection) or NEMA certification. For example, while IP65 or NEMA 3R suffices in some locations, IP66 enclosures or NEMA 4X cabinets provide the robust protection required for exposed or high-humidity settings.

The Brutal Attack: Vandalism and Physical Impacts

Nearly half of public charger outages stem from physical damage. Material selection plays a crucial role here. Aluminum enclosures—often rated IK09—are designed to deform under impact while preserving their seal. In contrast, more brittle materials may crack, exposing components and accelerating failure.

The Silent Cancer: Corrosion

In salt-rich coastal regions or high-salinity zones, corrosion is a guarantee—not a risk. Standard 304 stainless steel enclosures are vulnerable to chloride attack. Opting for cheaper materials to cut upfront costs often results in premature failures, escalating TCO and damaging reputation.

The Strategic Pivot — The “Charger Reliability Triad”

To combat these hidden threats and protect charger ROI, buyers must look beyond unit cost. We propose the Charger Reliability Triad as a strategic evaluation tool linking procurement to long-term network stability.

Pillar 1: The Physical Fortress (Resilience Engineering)

This pillar focuses on material and design decisions that reduce lifetime costs. The right enclosure strategy not only protects components but also minimizes dependence on external cooling or maintenance interventions.

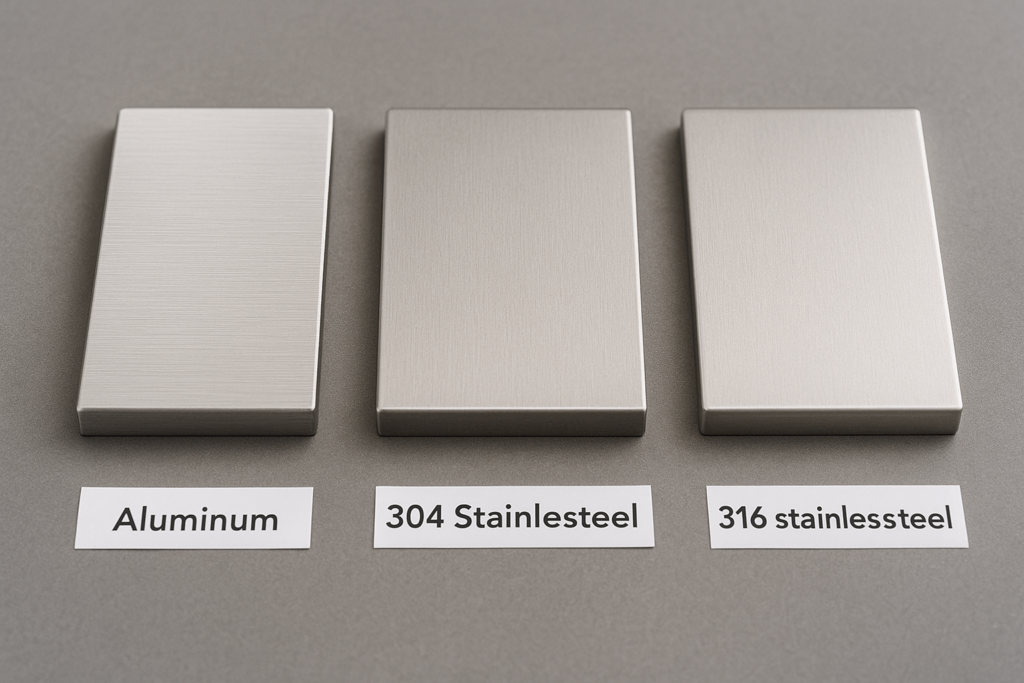

Beyond “Aluminum vs. Steel” to “Heat Dissipator vs. Insulator”

The material you choose affects your thermal management design. For high-output DC charging, aluminum enclosures function as passive radiators. With high thermal conductivity, they reduce internal temperatures, often eliminating the need for HVAC systems.

By contrast, stainless steel cabinets act as thermal insulators, often requiring active cooling systems that introduce new failure points and increase operating expenses.

Beyond “304 vs. 316” to “Geographic Risk Mitigation”

This isn’t just a material choice—it’s a geographic risk mitigation strategy. 316 stainless steel includes molybdenum, enhancing resistance to salt and chemical corrosion. For coastal networks or northern regions using de-icing agents, this upgrade is a necessity—not a luxury.

A marine-grade 316 EV charger cabinet is essentially an insurance policy against structural failure. It protects your ROI by ensuring long service life even in aggressive environments.

Pillar 2: The Intelligent Core (Operational Efficiency)

Enclosures enable—not just protect—functionality. A precisely built cabinet maintains internal temperature and humidity at optimal levels, supporting advanced features like:

- Predictive maintenance systems

- Integrated battery modules for peak shaving

- Secure data logging and real-time diagnostics

These features only function when protected from environmental disruptions. For system integrators and smart-grid partners, enclosure failure nullifies the entire value chain.

Pillar 3: The Manufacturing Alliance (Supply Chain Security)

Your cabinet supplier is a strategic partner. The manufacturing discipline of your vendor impacts everything—from delivery timelines to failure rates in the field.

The ISO 9001 Litmus Test

ISO 9001-certified manufacturers (like YISHANG) bring measurable benefits to B2B buyers:

- Repeatability across hundreds of units

- Process transparency and real-time QC logs

- Material traceability to validate steel grade and coating integrity

This isn’t about a certificate—it’s a system of verifiable accountability embedded in your supply chain.

The OEM/ODM Competitive Edge

For fast-growing EV brands or charger integrators, the ability to co-engineer hardware with your supplier is crucial. Through OEM/ODM collaboration, your product is optimized for performance, manufacturability, and differentiation.

Whether you’re sourcing a custom outdoor cabinet or an IP66-rated junction box, a precision fabricator can tailor the outcome to fit your electrical specs, mounting strategy, and aesthetic branding—giving you a long-term edge.

The Playbook — Winning Strategies for Real-World Scenarios

Now that we’ve established the Charger Reliability Triad, let’s put it into action. The following procurement plays are built for real-world use cases—each backed by the right enclosure design to maximize ROI and uptime.

The “Retail Magnet” Play (For Commercial & Retail Deployments)

Objective: Enhance customer experience and increase in-store conversions through aesthetic, silent, and branded EV chargers.

Strategy: Use custom-designed aluminum EV charger cabinets with smooth finishes and passive cooling. Aluminum’s natural conductivity allows for heat-efficient, silent operation—critical for retail parking lots or mixed-use spaces.

Partnering with an ODM EV charger cabinet supplier allows logos, coatings, and ambient lighting to be pre-integrated—reinforcing brand consistency. This turns the charger from utility into a visual asset.

The “Highway Oasis” Play (For Transport Corridors)

Objective: Maximize uptime in high-power, remote deployments along major roadways.

Strategy: Use modular DC fast charger enclosures with scalable footprints and high thermal redundancy. Cabinet design should accommodate 150kW–350kW chargers and support passive or hybrid cooling systems.

Collaborate with an ISO 9001-certified outdoor EV charger cabinet manufacturer to ensure manufacturing consistency across large volumes. Standardization here reduces field maintenance and shortens time-to-repair.

The “Coastal Resilience” Play (For Marine & High-Corrosion Zones)

Objective: Ensure operational durability despite persistent exposure to salt, fog, and UV.

Strategy: Specify corrosion-resistant 316 stainless steel EV charger cabinets with IP66 or NEMA 4X ratings. Demand TIG welding, multi-step passivation, and RoHS-compliant protective coatings.

In these regions, 304 steel will corrode within months. A marine-grade EV charging enclosure prevents failure due to chloride intrusion and ensures your total cost of ownership stays predictable.

Conclusion — The Choice Is Yours: A 73% Problem or a 99% Strategy?

The EV charging reliability gap is not caused solely by electronics or software. In many cases, it stems from structural neglect—treating the enclosure as a commodity instead of a core performance factor.

As a B2B buyer, your role is strategic. The EV charger cabinet you choose directly impacts system lifespan, uptime, and ROI. Field failures damage brand equity, incur costly service calls, and break the user experience loop.

Before placing your next large-volume order, ask your supplier:

- What thermal strategy do you recommend for our region and load profile?

- What are your material guarantees, and do you offer ISO 9001 traceability?

- Can you support OEM/ODM customization for our product line?

If these questions go unanswered or receive vague replies, consider alternatives.

A partner like YISHANG—with 26+ years in metal fabrication for EV infrastructure, full OEM/ODM capability, and international RoHS/ISO 9001 certifications—can help you deploy smarter, faster, and more profitably.

EV Charger Cabinet Procurement Checklist

- Assess your deployment region’s corrosion and climate exposure.

- Confirm the cabinet rating meets at least IP66 or NEMA 4X.

- Ensure material certification and traceability from your supplier.

- Review thermal strategy: passive or hybrid cooling?

- Verify OEM/ODM capabilities for your brand and volume needs.