The Premise: The Multi-Million Dollar Rattle (And Why Your “Simple” Clip Is Never Simple)

Imagine a new vehicle launch plagued by a persistent, low-frequency rattle from an interior door panel. It’s a subtle sound, but it triggers a cascade of warranty claims and damages brand perception. The root cause isn’t a major component failure; it’s a single, poorly specified sheet metal clip that couldn’t manage minute vibrations under thermal load.

This scenario powerfully illustrates a core truth for any procurement manager or engineer: a sheet metal clip is not a commodity fastener. It is a critical, engineered component where a single oversight in its design or material can have cascading consequences on performance, assembly cost, and long-term product reliability.

This playbook is designed for strategic buyers who understand that true value lies beyond the per-piece price. We will dismantle the process of creating custom sheet metal clips, framing it as an interconnected sequence of critical decisions that directly impact your bottom line. Whether you’re sourcing clips for automotive assemblies, consumer electronics, or HVAC systems, the principles remain the same.

The goal is to transform this humble component from a potential failure point into a force multiplier—an elegant fastening solution that enhances product quality, streamlines assembly, and builds a competitive advantage.

✅ Related Use Case: Custom Progressive-Stamped Clips for Electronic Housings

Before a single line is drawn in CAD, the first decision is to define the clip’s primary engineering function. A strategic approach classifies clips by the engineering problem they solve. This function-first methodology ensures the final component is purpose-built for its environment, a critical first step in mitigating design risk.

The Challenge of Joining Panels

When the primary objective is the secure attachment of components, the focus is on achieving a firm, vibration-free assembly. This is a common application where metal clips replace traditional screws to speed up production and simplify service.

In these scenarios, specific geometries are employed to manage clamping forces. For instance, U-Clips and J-Clips are designed for edge panel fastening, sliding over a flange to provide a robust connection. S-Clips, with their unique geometry, are the ideal solution for joining parallel panels, creating a strong, hidden connection indispensable in appliance, aerospace, and automotive assemblies.

The Challenge of Dynamic Environments

Many applications are not static. Components are subjected to thermal cycling, constant vibration, or require a reliable electrical path. In these dynamic environments, a simple joining clip will fail. The engineering challenge shifts from connection to active management of environmental forces.

This is where specialized designs like Floating or Expansion Clips become critical. Commonly used in solar panel racking, architectural facades, or automotive roof structures, these clips feature a sliding mechanism that allows a panel to expand and contract with temperature changes without inducing stress on the fastening points.

Simultaneously, ensuring electrical safety is paramount. Grounding Clips are engineered for this task, designed to create a reliable, low-impedance path to a metal frame. Many feature sharp tines that pierce non-conductive coatings like paint, guaranteeing a solid metal-to-metal contact for dissipating static electricity or grounding PCBs.

💡 Related spec sheet: RoHS-compliant grounding clip designs

The Challenge of High-Tech Integration

In advanced electronics, a clip must often perform multiple functions. The engineering problem becomes one of sophisticated integration, where the clip is both a mechanical fastener and part of a thermal or electrical system.

For example, modern Printed Circuit Boards (PCBs) require shielding to prevent electromagnetic interference (EMI). The solution is a removable Faraday cage, made possible by EMI/RFI Shielding Clips. These small, surface-mounted clips are soldered to the PCB, allowing a metal shield to be snapped into place without secondary soldering, enabling easy rework.

Similarly, the thermal management of processors relies on maintaining constant pressure between the chip and its heat sink. Heat Sink Clips are designed to apply a precise and consistent spring force, ensuring optimal thermal contact. This method is far more reliable than screws, which can cause uneven pressure or damage the PCB.

Decision Point Two: The Material Trade-Off Matrix—A High-Stakes Balancing Act

Once the function is defined, the next decision is material selection. This is not a simple line item; it is a high-stakes balancing act. Choosing the wrong material can lead to premature failure, compromised performance, or unnecessary cost. A strategic buyer approaches this as a series of trade-offs to pinpoint the optimal balance for the application.

Trade-Off #1: Absolute Strength vs. Resilient Toughness

For many spring clip applications, high-carbon steels are the workhorses. However, a critical trade-off exists between hardness and toughness, best exemplified by 1095 vs 1075 steel.

- 1095 High-Carbon Steel, with its higher carbon content (~0.95%), can be heat-treated to a greater hardness (55–60 HRC). This gives it superior wear resistance, making it ideal for clips that experience repeated sliding contact. The price for this hardness, however, is reduced toughness, making it more brittle.

- 1075 High-Carbon Steel, with a carbon content around 0.75%, is slightly softer (50–55 HRC) but significantly tougher. It offers superior shock absorption, making it the better choice for applications in high-vibration or impact-prone environments where resilience is more critical than absolute hardness.

💡 Use Case Insight: spring steel clips for vibration dampening in electric motor housings

Trade-Off #2: Environmental Defense vs. Peak Spring Performance

When a clip is exposed to moisture, stainless steel is the obvious choice. Yet, a common mistake is to assume all stainless steels are equal for spring applications. This paradox is best seen when comparing AISI 301 vs 304 stainless steel.

- AISI 304 Stainless Steel is the industry standard for corrosion resistance, with higher chromium (18–20%) and nickel (8–12%) content. However, it does not respond well to the work-hardening required to create a good spring and is prone to elastic fatigue, losing clamping force over time.

- AISI 301 Stainless Steel is specifically engineered for spring applications. Its chemistry allows it to work-harden significantly, dramatically increasing its tensile strength and giving it the high elasticity essential for a long-lasting spring. For a structural spring clip, 301 is the performance choice.

🌍 Material sourcing tip: Choose RoHS-compliant stainless steel 301 for export-grade spring clips.

Trade-Off #3: Initial Cost vs. Mission-Critical Reliability

In electrical applications, the material trade-off becomes a direct calculation of risk and Total Cost of Ownership (TCO). The showdown between Beryllium Copper (BeCu) vs. Phosphor Bronze is a classic example. A buyer focused solely on initial price will choose Phosphor Bronze, as it can be up to five times cheaper. An experienced buyer, however, must consider the cost of failure.

| Feature Beryllium Copper (BeCu) Phosphor Bronze | ||

|---|---|---|

| Fatigue Life (Cycles) | > 1,000,000 | 200,000–300,000 |

| Conductivity (% IACS) | 22–60% | 15–20% |

| Stress Relaxation | Very Low | Moderate |

| Initial Cost | High | Low |

| Total Cost of Ownership | Low | High |

Phosphor Bronze offers moderate spring properties, making it suitable for general-purpose contacts. However, it has a lower fatigue life and is susceptible to stress relaxation at elevated temperatures. Beryllium Copper offers unparalleled fatigue life, often exceeding one million cycles, and superior resistance to stress relaxation.

📌 Recommended Application: beryllium copper clips for PCB contact integrity under thermal load

For any mission-critical application—aerospace, medical, or automotive—the superior reliability of BeCu translates to a far lower TCO. The higher initial investment is an insurance policy against catastrophic field failures and costly downtime.

Decision Point Three: The Design Gauntlet—How Geometry Governs Function

With material selected, the engineering journey enters the most unforgiving stage: design geometry. This is where the clip evolves from a conceptual solution into a manufacturable, high-performance component. The geometry must serve its function with precision, maintain integrity under stress, and fit seamlessly into the assembly process—all while remaining cost-effective to produce.

Spring Dynamics and Force Calibration

A well-engineered clip behaves like a spring with a purposefully tuned force curve. The geometry governs how much deflection occurs under load and how that translates into holding force. Even minor variations in arc length, leg angle, or bend radius can shift the force output dramatically.

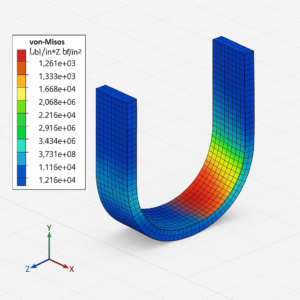

Designers often use Finite Element Analysis (FEA) to simulate how a clip behaves under deformation. A properly calibrated FEA model predicts spring force over displacement and highlights high-stress zones that may become future failure points. A clip that deforms elastically and returns to shape after thousands of cycles is ideal; one that enters plastic deformation or stress fracture modes is a ticking time bomb.

🔧 Design insight: Use FEA-backed clip profiles for consistent springback and dimensional tolerance control in progressive stamping.

Locking Features and Anti-Rotation Strategies

In many assemblies, clips must remain securely in place during handling, vibration, or torque-induced movement. That requires thoughtful incorporation of locking mechanisms into the geometry. These features may include:

- Barbs or Retention Tabs that dig into plastic or metal substrates.

- Snap Arms or Detents that resist pullout.

- Anti-Rotation Shoulders to prevent twist under load.

Each design choice must balance retention strength with ease of installation. A clip that is too secure may deform the substrate or be impossible to remove during service. A clip that is too loose risks disengagement or rattle.

💡 Application note: anti-vibration metal clips for appliance control panels require built-in redundancy against thermal expansion or dynamic loading.

Geometry for Automated Assembly (DFA)

Design for Assembly (DFA) is a make-or-break factor in high-volume production. An elegant geometry on paper may prove useless if it cannot be handled or inserted by automated machinery. Key design considerations include:

- Lead-In Angles to guide insertion tools.

- Chamfered Edges to prevent hang-ups.

- Flat Pick Zones for robotic grippers.

Well-executed DFA geometry reduces cycle time, lowers labor cost, and ensures consistent insertion force—critical for applications like HVAC enclosures, battery packs, or automotive dashboards where hundreds of clips may be installed per unit.

Decision Point Four: Process Compatibility—Marrying Design to Manufacturing Reality

Even the most precisely designed clip can fail if it is not aligned with the realities of manufacturing. At this stage, strategic buyers must ensure that the clip’s geometry and material are matched to industrial processes that enable consistent, scalable, and cost-effective production.

Stamping and Forming Constraints

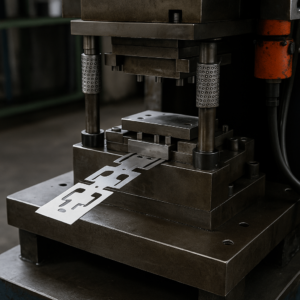

Sheet metal clips are typically produced using progressive die stamping, where metal coils are fed through a sequence of dies that progressively form the part. Each step introduces geometric and material limits:

- Minimum Bend Radius must be respected to avoid cracking or stress risers.

- Grain Direction influences the part’s ability to absorb stress without deforming.

- Hole-to-Edge Distance affects punch integrity and burr formation.

Designs that disregard these constraints may function in theory but introduce downstream issues in die wear, material scrap, and line stoppages.

💡 Tooling tip: Collaborate with suppliers early using DFM simulation to predict springback, optimize layout, and reduce tooling rework in clip production.

Coatings and Corrosion Strategy

For outdoor, marine, or high-humidity environments, coating choice can make or break a clip’s longevity. Material choice is only half the story—surface finishing is the other. Depending on end-use, options include:

- Zinc Electroplating, the go-to for cost-effective corrosion resistance.

- Dacromet® Coating, for automotive-grade corrosion protection without hydrogen embrittlement.

- Black Oxide, used for heat-treated clips needing low reflectivity and mild oxidation defense.

🧪 Compliance insight: Use RoHS-compliant coatings such as trivalent chromates or water-based passivation to meet global export requirements.

Heat Treatment and Spring Performance

For high-carbon and alloy steels, heat treatment is required to achieve the proper balance between hardness and ductility. This step often includes:

- Austenitizing & Quenching, for strength.

- Tempering, for resilience.

- Stress-Relief Annealing, to reduce warpage post-forming.

Poor thermal control or inconsistent soak time during heat treatment can result in part distortion, dimensional drift, or premature fatigue.

🔥 Manufacturing note: Partner with vendors who offer in-house hardening ovens or third-party certified heat treatment to ensure repeatability and mechanical property validation.

Decision Point Five: Supply Chain Reality—Choosing a Manufacturing Partner Who Gets It

A perfect design backed by ideal materials and process compatibility can still fail if the right manufacturing partner is not selected. At this stage, strategic buyers must shift from design validation to execution assurance. The choice of supplier determines whether your custom sheet metal clip performs consistently across thousands or millions of units.

Supplier Capabilities and Tolerances

Not all suppliers are equal when it comes to manufacturing sheet metal clips. A true engineering partner offers more than metal cutting—they offer process control, testing capabilities, and tooling design expertise. Key differentiators include:

- In-House Tooling Fabrication: Enables rapid prototyping and tighter quality control.

- Statistical Process Control (SPC): Maintains dimensional accuracy and process repeatability.

- Precision Die Maintenance: Prevents tool wear from degrading part consistency over long production runs.

For high-performance clips, tolerances in the range of ±0.05 mm may be required—especially when clips interface with plastic housings or PCB assemblies. Verifying that a supplier can hold these tolerances consistently across production batches is non-negotiable.

📏 Sourcing insight: Select suppliers with verifiable sheet metal clip tolerance control procedures and digital measurement records.

Quality Systems and Traceability

Clips may be small, but they require big-picture thinking when it comes to quality assurance. Ask whether the supplier is certified to international standards like ISO 9001, and more importantly, whether they maintain:

- Incoming Material Inspection Protocols to verify alloy and hardness.

- In-Process Dimensional Checks with calibrated gauges or optical systems.

- Lot Traceability Systems that link batches to raw material heat numbers and production parameters.

These systems are especially vital for industries like automotive, aerospace, or medical devices, where a single defective clip can trigger costly recalls or compliance violations.

Global Logistics and Volume Flexibility

Today’s supply chains demand more than technical capability. Your clip supplier must also offer logistical agility. That means:

- Flexible MOQ (Minimum Order Quantities) to accommodate development runs or sudden demand shifts.

- Lead Time Transparency, including tooling setup and batch turnaround.

- Export Experience with packaging compliance (e.g., RoHS labeling, barcoded traceability) for international markets.

For buyers sourcing globally, a supplier’s ability to consolidate shipments, pre-assemble subcomponents, or provide just-in-time delivery can create significant downstream savings and inventory efficiency.

Strategic ROI: Reframing the Clip as a Long-Term Investment

To conclude, it’s essential to recognize that a sheet metal clip is not just a fastener—it is a long-term investment. The right clip reduces total lifecycle costs, enhances product reliability, and improves user satisfaction. Understanding the true return on investment (ROI) requires looking far beyond the purchase order.

The Cost of Failure vs. the Value of Prevention

Failure analysis across automotive, aerospace, and consumer electronics consistently shows that small, inexpensive components like clips often cause outsized problems when they fail. The cost of field failures includes:

- Warranty Claims and Repairs

- Brand Damage from Negative User Experience

- Line Shutdowns due to Assembly Defects

By contrast, investing slightly more in an optimized clip—one designed for fatigue resistance, corrosion stability, and robust retention—can yield exponential savings. This is the essence of preventative ROI: eliminating future failures before they happen.

💡 Cost modeling tip: Use a custom clip ROI calculator to compare low-cost options vs. precision-engineered clips over full lifecycle.

Time-to-Market Advantage

Custom clips that are designed with Design for Assembly (DFA) and Design for Manufacturability (DFM) principles can significantly accelerate production ramp-up. Standard clips often require workarounds, secondary fasteners, or field modification.

A clip tailored to your part geometry, automation setup, and service requirements removes friction throughout the product lifecycle—from prototyping to mass production. This streamlining leads to:

- Fewer Engineering Change Orders (ECOs)

- Faster Tooling Sign-Off

- Quicker Line Integration

The result is faster time-to-market and earlier revenue capture—especially critical in competitive categories like consumer electronics and modular HVAC.

Lifecycle Performance Metrics

Strategic sourcing decisions must be backed by measurable results. An optimized clip can contribute to:

- Improved NVH (Noise, Vibration, Harshness) Ratings

- Enhanced Thermal or EMI Shielding

- Reduced Assembly Time per Unit

These benefits compound over production volume. For example, a 5-second reduction in assembly time per unit translates to significant labor savings across thousands of units. Similarly, a clip that eliminates buzz or rattle improves customer satisfaction scores and reduces post-sale service calls.

Final Word: Strategic Components Deserve Strategic Thinking

Sheet metal clips may not dominate the BOM, but they often define the product experience. A strategic buyer or engineer recognizes that real value lies not in the lowest unit cost, but in the highest total system performance.

By applying a rigorous, function-first methodology to clip specification—material, design, process, supplier—you turn a potential liability into a strategic advantage.

Whether you’re designing for thermal cycling, EMI shielding, or assembly time reduction, the clip you choose quietly underpins the success of your product in the field.

📦 Looking for an export-ready partner? YISHANG is an ISO 9001-certified manufacturer of custom sheet metal clips, supporting OEM & ODM projects across automotive, appliance, and electronics sectors.

✅ Materials: stainless steel, phosphor bronze, BeCu, low-carbon steel, and more

✅ Services: stamping, coating, heat treatment, quality control, RoHS packaging, global logistics

👉 Contact us now to discuss your project specs, request a drawing review, or request a rapid quote.