In modern global manufacturing, the line between market leadership and obsolescence is often measured in microns. For overseas wholesale procurement managers, supply chain directors, and strategic buyers tasked with sourcing high-volume metal components, the choice of a manufacturing partner is more than a line item on a budget—it’s a critical decision that dictates product quality, supply chain resilience, and ultimately, the profitability of an entire product line. While the allure of low-cost outsourcing has long been the default path, a growing number of industry leaders are confronting a stark reality: the advertised price of a part rarely reflects its true cost.

This guide is not another catalog of services or a list of machine specifications. It is a deep dive into the complex, high-stakes world of advanced machining solutions—crafted for decision-makers who understand that “good enough” is a liability that compounds over time, especially at scale. We’ll unpack the silent profit killers embedded in fragmented supply chains and spotlight the technical mastery required to solve the toughest CNC machining challenges. This is a playbook for moving beyond transactional vendors and building real manufacturing advantage through strategic in-house precision machining.

The Real Cost of “Good Enough”: Why Your Current Machining Partner is Silently Killing Your Profit Margin

The in-house versus outsourced machining debate is often oversimplified as a trade-off: upfront capital expenditure versus lower per-unit pricing. For wholesale buyers managing large-scale production, this is dangerously incomplete. The real cost of outsourcing reveals itself through a series of hidden taxes—eroding efficiency, security, and long-term value.

Imagine a scenario: your overseas supplier delivers the first 1,000 units flawlessly. Everything meets spec. But by the hundredth batch, tolerances drift. Surface finishes degrade. Fitment issues start surfacing on the assembly line. This is Quality Drift—a subtle but destructive creep that arises when there’s no direct control over production processes. It introduces costly rework, warranty claims, and in worst cases, product recalls.

Then there’s the Communication Tax. Each time a design revision requires navigating time zones, language gaps, or intermediary account reps, responsiveness suffers. That agile engineering fix you needed yesterday becomes a two-week delay. Launch timelines slip. Internal teams stall. For procurement, this isn’t just inconvenience—it’s a tangible cost to agility and time-to-market.

Perhaps the most overlooked but critical issue is the erosion of IP protection. Every shared CAD file, every disclosed tolerance, becomes a point of vulnerability. In a fragmented supply chain, proprietary know-how doesn’t just leak—it’s often absorbed, repackaged, and commoditized. In sectors where innovation is strategic currency, this loss is irrecoverable.

The alternative? A model of Total Control through in-house precision machining. This isn’t about insourcing for the sake of it—it’s about owning outcomes. It allows you to eliminate quality drift via unified QC protocols, collapse communication tax by co-locating design and production, and safeguard intellectual property inside your firewall. It’s a move from risk exposure to strategic resilience.

Deep Dive: Conquering the “Unmachinable” – A Material-by-Material Playbook

A machining partner’s true value lies not in a list of materials they “can handle,” but in their ability to solve the real-world problems those materials introduce. Challenging substrates like stainless steel or aluminum aren’t just difficult—they’re unforgiving. This section demystifies what it takes to machine them right, every time.

Case Study: The “Work Hardening” Battle in Stainless Steel

The Procurement Manager’s Problem: “Why do my 316 stainless steel parts keep failing surface inspection? Why are tool costs ballooning mid-run? Why does each cut seem harder than the last?”

This is work hardening in action. Austenitic grades like 304 and 316 build up heat at the tool-material interface. Without excellent heat evacuation, the steel surface becomes tougher with each pass. As a result, tool wear accelerates, finishes deteriorate, and dimensional accuracy plummets.

The Expert Solution: For 304, the strategy is aggressive engagement—high feed rates and deeper passes prevent rubbing and minimize thermal load. With 316, the game changes. Slower speeds with higher chip loads stabilize the cut zone and stay ahead of the hardened layer. Tooling choice is critical: sharp-edge carbide with frequent indexing. Flood coolant—high-pressure, water-soluble—is non-negotiable. Rigidity in both fixturing and programming ensures process reliability.

Case Study: The “Built-Up Edge” Nightmare in Aluminum Alloys

The Quality Engineer’s Problem: “Our 6061 aluminum parts smear under finish cuts. Tool life is unpredictable. Surface quality varies lot-to-lot.”

The culprit is Built-Up Edge (BUE)—a condition where aluminum welds to the cutting edge, distorting the geometry and inducing vibration. Long, stringy chips make evacuation difficult, adding to the chaos.

The Expert Solution: Geometry, speed, and coolant are the trifecta. For 6061, we specify polished, high-helix tools (35°–45°), typically 2 or 3 flute. ZrN-coated or uncoated tools prevent adhesion better than TiN. Spindle speeds should push aluminum’s limits, paired with elevated feed rates to maintain chip load. Coolant? Always. Trochoidal toolpaths reduce heat spikes and stabilize engagement.

The Digital Twin Mandate: Achieving Zero-Scrap Production with Live Process Feedback

Volume without repeatability is a liability. For procurement teams ordering tens of thousands of components, consistency is non-negotiable. That starts with simulation.

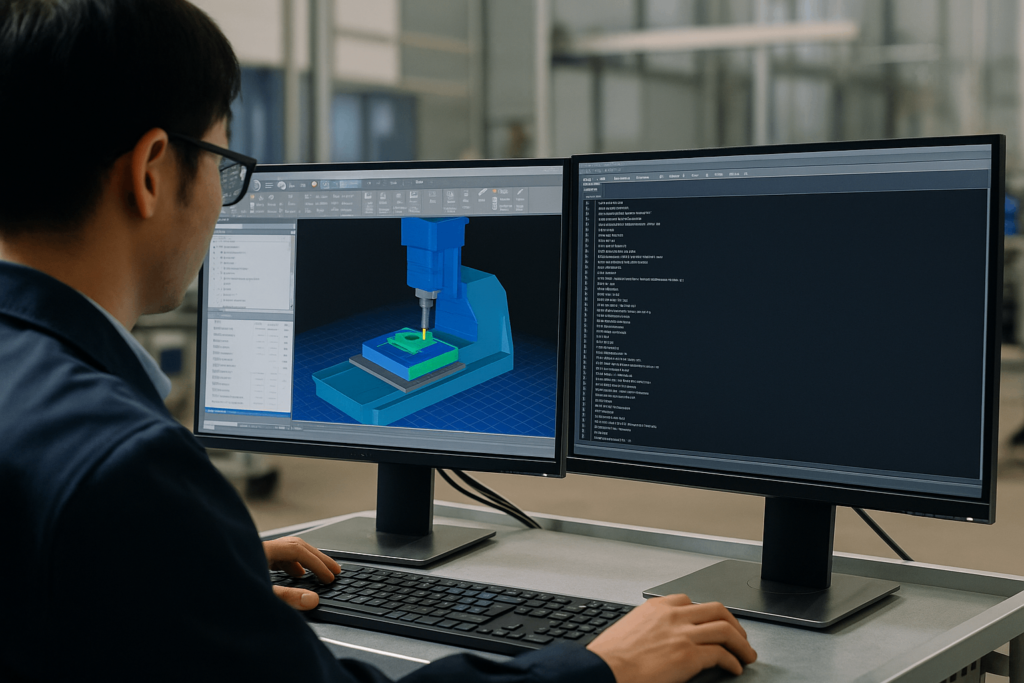

We begin with a digital twin—a CAM-modeled replica of the entire machining cycle. Toolpaths, cut order, material removal rates, chip loads—it’s all validated before a single spindle turns. This simulation detects collisions, optimizes runtime, and ensures first-pass success.

But simulation is just the beginning. We close the loop with in-cycle inspection. Using spindle probes and non-contact laser metrology, our machines monitor dimensional fidelity in real time. Micron-scale deviations trigger automatic tool offset corrections. What does this mean for buyers? It means no scrap, no surprises, no downstream fire drills.

It’s the convergence of virtual optimization and live feedback that transforms quality from statistical to systemic.

The Engineer’s Roundtable: Real-World DFM Wins That Slashed Client Costs

Smart design equals smart manufacturing. The sooner a machinist touches your drawing, the more they can help you save. These DFM examples show how collaborative engineering transforms cost curves without sacrificing function.

Case Study 1: Why Sharp Corners Multiply Cost

Original Design: An aluminum housing with tight internal corners that looked good on screen—but screamed complexity on the shop floor.

The Problem: Milling tools are round. Sharp interior corners require micro-tools or EDM—a cost amplifier.

The DFM Fix: We proposed internal radii no less than one-third cavity depth. This allowed standard tools, faster feeds, and superior finishes.

| DFM Principle Original Design Flaw Optimized Solution Quantifiable Impact | |||

|---|---|---|---|

| Corner Geometry | Sharp Internal Corners | Add radii ≥ 1/3 depth | 70% faster machining time per part |

| Part Consolidation | 5-Part Bolted Assembly | Single 5-Axis Machined Component | 80% fewer parts, no assembly time |

Result: Drastic cycle time reduction, fewer finishing operations, and elimination of assembly labor.

Case Study 2: Consolidating Parts for Lifecycle Gains

Original Design: A five-piece mechanical assembly that required fastening, inspection, and multi-step QA.

The Problem: Tolerance stack-ups created unpredictable fits. Fastener loosening caused early failures.

The DFM Fix: We consolidated the unit into a single multi-axis machined body. This eliminated interfaces, reduced potential failure points, and shortened assembly time to zero.

Result: Better structural integrity, lower QC burden, fewer SKUs—and a BOM cost reduction that procurement could take straight to the CFO.

Conclusion: Are You Buying a Machining Service, or Investing in a Manufacturing Partner?

In today’s environment, where supplier churn is high and global uncertainty is the norm, procurement is no longer a passive function. It is a value enabler. Choosing the right machining partner is not about rates per part—it’s about readiness, reliability, and resilience.

Everything discussed—from combatting outsourcing’s hidden costs to solving metallurgical machining puzzles, from simulating perfection to embedding real-time QC—points to one truth:

Precision is not a capability. It’s a culture.

The next RFQ isn’t just a price request. It’s an opportunity to shift your supply chain from cost center to competitive asset.

Let’s start with a conversation. Request your complimentary Design for Manufacturability (DFM) assessment today—and experience how true CNC partnership redefines quality, cost, and delivery.

Frequently Asked Questions (FAQ)

Q1: What is the biggest machining challenge with stainless steel?

A: Work hardening in austenitic stainless steels like 304 and 316 is a common issue. It requires precise control of feed rates, cutting depth, and coolant application to maintain tool life and dimensional accuracy. Learn more about stainless steel CNC machining

Q2: How does a digital twin improve CNC machining accuracy?

A: A digital twin simulates the machining process before cutting begins. It allows engineers to validate toolpaths, predict cycle times, and avoid collisions—ultimately helping reduce scrap rates and boost repeatability.

Q3: Can Design for Manufacturability really reduce CNC costs?

A: Yes. Through proper DFM techniques such as radius adjustments and part consolidation, manufacturers can shorten cycle times, reduce tooling wear, and eliminate unnecessary assemblies.

Q4: Why is in-house precision machining better for IP protection?

A: Keeping machining operations in-house ensures tighter control over proprietary designs and specifications. It avoids IP leakage and supports secure, confidential production.

Q5: Which industries benefit most from in-house CNC machining?

A: Automotive, aerospace, medical equipment, consumer electronics, and energy storage sectors—industries that require high-volume, precision-critical parts—gain significant value from in-house machining control.

Looking for more detail on our CNC capabilities? Visit our CNC precision machining services page.