Aluminum checker plate, often referred to as tread plate or diamond plate, is a material frequently specified for its functional, anti-slip surface. However, for the discerning engineer, procurement manager, or project specifier, its value extends far beyond this single attribute. It is a highly engineered material where metallurgical science, manufacturing precision, and design intent converge to solve complex challenges in durability, structural efficiency, and safety.

This guide moves beyond a surface-level overview. It is a comprehensive technical resource designed for professionals who make critical decisions about material sourcing and application. We will dissect the key performance indicators, fabrication considerations, and quality assurance metrics that separate a commodity product from a high-performance, reliable asset. This is a masterclass in aluminum checker plate, providing the expert insights required to specify with confidence and maximize project value.

Part 1: Aluminum Checker Plate Applications for Industrial & Commercial Projects

Every material specification begins with a clear understanding of the project’s demands. For aluminum checker plate sheets, their adoption is driven by a unique combination of properties that deliver tangible benefits in commercial, industrial, and transportation sectors. Understanding this value proposition is the first step in leveraging its full potential for large-scale projects.

Diamond Plate Wall Panels & High-Traffic Protection

In modern architecture and high-traffic commercial spaces, material selection is a balance of aesthetics and lifecycle cost. Aluminum checker plate has emerged as a preferred material for its ability to deliver both. Its use in diamond plate wall panels and wainscoting is not merely a design choice; it’s a strategic decision to protect high-traffic areas like corridors, loading docks, and commercial kitchens from constant impact and abrasion. Unlike drywall or wood, which require frequent repair and repainting, a properly installed checker plate wainscot offers a permanent, low-maintenance solution that significantly reduces long-term operational costs.

Furthermore, its non-porous, corrosion-resistant surface makes it ideal for hygienic environments like food processing plants and laboratories. The material is easy to clean and can withstand harsh cleaning agents, ensuring it meets stringent sanitation standards while providing a safe, slip-resistant surface for personnel. This combination of durability and low maintenance is a key purchasing driver for facility managers and commercial builders.

Aluminum Tread Plate in Automotive & Marine Engineering

In the automotive and marine industries, performance is measured in efficiency, safety, and longevity. Aluminum checker plate is a key enabler in all three areas. The quintessential aluminum truck bed liner is a prime example of its utility. While standard plastic liners can crack and trap moisture, leading to corrosion, an aluminum checker plate sheet floor provides a structurally rigid, corrosion-resistant, and genuinely anti-slip work platform that lasts the lifetime of the vehicle. Its superior strength-to-weight ratio also contributes to increased payload capacity and improved fuel efficiency.

For marine applications, the material requirements are even more stringent. Constant exposure to saltwater creates an intensely corrosive environment that would destroy most metals. This is where the specification of marine grade aluminum becomes critical. Alloys from the 5xxx series, particularly 5052, 5083, and 5086, are engineered with high magnesium content to provide exceptional resistance to saltwater corrosion. A boat deck fabricated from the correct marine-grade checker plate is a critical structural component, designed to endure decades of harsh environmental abuse while providing a safe, multi-directional slip-resistant surface for the crew.

Part 2: How to Specify Aluminum Checker Plate for Engineering Performance

With the application defined, the focus shifts to the technical blueprint. For a wholesale buyer or project engineer, this is the most critical phase. The choices made here regarding alloy, temper, tread pattern, and base thickness are not arbitrary; they are engineering decisions that directly impact structural performance, fabrication costs, and lifecycle outcomes.

Alloy Selection: Comparing 3003, 5052, and 6061 for Industrial Use

The alloy is the metallurgical DNA of the checker plate, defining its core mechanical properties. A mis-specification at this stage can lead to premature failure or unnecessary costs. The three most common alloys—3003, 5052, and 6061—have distinct performance profiles that every specifier must understand.

- 3003: The Formable Workhorse. This manganese-family alloy is prized for its excellent formability and workability. It is the ideal choice for applications requiring complex bending or deep drawing, such as custom enclosures or architectural elements. While it offers good corrosion resistance for general use, its strength is moderate and it is not heat-treatable, making it unsuitable for structural applications.

- 5052: The Marine & Durability Champion. As a high-magnesium alloy, 5052 offers superior corrosion resistance, especially in saltwater environments, making it the standard for marine applications. It is one of the strongest non-heat-treatable alloys, with significantly higher tensile and fatigue strength than 3003. This strength comes with a trade-off: reduced formability. Bending 5052 past a 90-degree angle requires careful technique and a larger bend radius to avoid cracking.

- 6061: The Structural Powerhouse. This heat-treatable magnesium-silicon alloy is the workhorse for structural applications. In its T6 temper, it provides an excellent strength-to-weight ratio, essential for load-bearing ramps, platforms, and framing. However, this strength introduces significant fabrication challenges. 6061 is the least formable of the three and is notorious for cracking if bent improperly. Furthermore, welding creates a weakened Heat-Affected Zone (HAZ) that must be accounted for in structural design.

📎 Need help choosing the right alloy for your project? Our custom aluminum fabrication experts support OEMs with full-spec alloy matching.

Quick-Decision Matrix: Alloy Properties for Professional Specifiers

| Property 3003 Aluminum 5052 Aluminum 6061 Aluminum | |||

|---|---|---|---|

| Primary Role | High Formability, General Use | Extreme Durability & Corrosion Resistance | High Structural Strength |

| Formability | Excellent | Good | Fair (Prone to cracking) |

| Strength (Tensile) | Medium (~110–240 MPa) | Medium-High (~190–320 MPa) | High (T6 Temper, ~240 MPa) |

| Corrosion Resistance | Good | Excellent (Marine Grade) | Good |

| Weldability | Excellent | Good | Good (Requires special technique, creates HAZ) |

| Heat-Treatable | No | No | Yes |

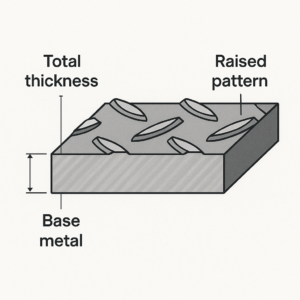

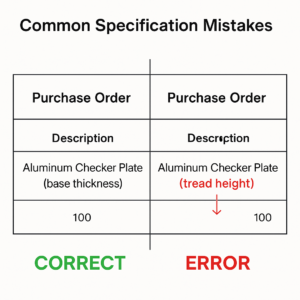

Base Thickness vs. Nominal Thickness: Avoiding Structural Misjudgments

While alloy selection defines core mechanical behavior, checker plate thickness governs structural integrity and load-bearing capacity. Unfortunately, this is also where misleading product labeling and incomplete technical data often misguide specifiers.

Many suppliers market checker plate sheets by their total nominal thickness—including the raised tread pattern—rather than the base aluminum. For example, a “3mm checker plate” might actually have only 2.2mm of substrate, with the remaining 0.8mm coming from the raised bars. This discrepancy creates real-world risks when relying on plate strength calculations based on nominal thickness.

For load-bearing applications such as warehouse ramps, loading docks, or heavy-duty flooring, always specify and verify base metal thickness, not total sheet thickness. Engineering calculations, including yield load and deflection limits, must use actual substrate thickness. Tolerance standards such as ASTM B209 for aluminum plate provide the reference point for dimensional accuracy.

📌 Our surface finishing services include pre-measured, gauge-certified checker plates with base thickness documentation, ensuring full compliance with load-bearing specs.

To avoid structural underperformance or code violations, procurement teams must demand technical drawings or mill test reports that clearly distinguish between nominal and effective thickness. Reliable OEM suppliers will always provide this clarity.

Checker Plate Patterns and Their Functional Impact

The raised pattern is not a decorative flourish—it’s a functional safety feature. However, not all tread patterns perform equally underfoot. The three most common designs are:

- 5-Bar Tread: The industry standard for industrial flooring and work platforms. Its multi-directional pattern provides excellent slip resistance, even in wet or oily conditions.

- Diamond or Single-Bar: Common in decorative cladding and light-duty applications. Provides less aggressive grip but a sleeker appearance.

- Propeller Pattern: A stylized variant often used in architectural or vehicular applications. Lower slip resistance but unique visual identity.

In industrial environments such as oil & gas facilities, slip-resistance data (often measured in coefficient of friction or ramp test results per DIN 51130) should guide pattern selection—not visual preference.

Part 3: Welding, Bending & Surface Finishing — Fabrication Strategies for Long-Term Performance

Selecting the right aluminum checker plate is only half the equation; ensuring it performs as expected depends heavily on how it is fabricated. Welding, bending, heat treatment, and finishing processes all introduce mechanical and dimensional variables that impact longevity and field performance. This section helps engineers and buyers anticipate those risks and make informed fabrication decisions.

Welding Aluminum Checker Plate: Managing Heat-Affected Zones (HAZ)

While aluminum is highly weldable, checker plate welding presents additional challenges due to the raised tread pattern and alloy-specific behavior. The raised pattern disrupts weld bead continuity, and alloys like 6061, despite being strong, are prone to heat-induced softening in the HAZ (Heat-Affected Zone). This leads to reduced post-weld strength unless the area is properly reinforced or post-heat-treated.

To mitigate this:

- Use filler material compatible with both the base metal and service environment (e.g., 5356 for 5xxx alloys).

- When welding 6061, expect a 30–40% drop in strength at the HAZ. Design structural elements with this degradation factored in.

- Clamp securely to minimize warping, especially for long checker plate sheets or large deck panels.

📊 Diagram Suggestion: A simple cross-section of a welded aluminum checker plate panel showing base material, raised tread, HAZ width, and strength loss zones.

Engineers should require post-weld inspections using dye penetrant or ultrasonic testing in critical load-bearing zones.

Bending and Forming Checker Plate: Accommodating Raised Surface Geometry

The tread pattern enhances traction, but it also creates uneven thickness that complicates precision bending. When forming aluminum checker plate:

- Always bend with the grain and align bends to avoid placing the raised bars on the compression side.

- Use generous bend radii—minimum 1.5x material thickness—to prevent cracking.

- For harder alloys like 6061-T6, annealing or selecting a -O or -T4 temper may be required before forming.

Even “formable” alloys like 5052 can fail under tight radii if the raised pattern interferes with die alignment. Always run test bends when prototyping custom enclosures or structural brackets.

🔧 Tip: If you’re unsure about bend radius limits for your alloy temper, consult our custom aluminum fabrication support team. We provide forming feasibility reviews during pre-production.

Surface Finishing Options: Protection, Grip & Aesthetics

The natural corrosion resistance of aluminum checker plate can be enhanced with surface treatments tailored to end-use requirements:

- Mill Finish: The standard as-rolled finish, suitable for interior or non-aesthetic applications.

- Anodizing: Adds abrasion resistance and color options, though tread patterns may create uneven dye absorption.

- Powder Coating: Provides both protective and aesthetic value; requires surface preparation to avoid flaking on raised areas.

- Non-Slip Coatings: In extreme slip-risk environments, adding epoxy grit or textured polyurethane coatings improves safety far beyond tread-only reliance.

🧪 Yishang’s surface finishing services ensure proper pre-treatment for powder-coated checker plate, including deburring, degreasing, and edge sealing—vital for long-term adhesion.

For OEMs in sectors like automotive, agriculture, or energy, ensuring surface performance isn’t just an aesthetic concern—it’s a product liability issue. Reputable manufacturers like Yishang, with over 26 years of experience in industrial metal processing, understand the tolerances and treatments required for checker plates that perform in the real world.

Part 4: How to Evaluate Checker Plate Quality and Supplier Risk

While aluminum checker plate is widely available, not all products are created equal. Procurement teams must distinguish between high-performance engineered materials and cost-cutting substitutes that risk structural failure, premature corrosion, or non-compliance with safety regulations. In this section, we address common misconceptions, quality pitfalls, and practical methods to vet suppliers.

Common Specification Mistakes and Quality Traps

One of the most frequent errors in checker plate procurement is over-specifying or under-specifying based on incomplete or misleading data.

- Over-engineering: Specifying 6061-T6 for a light-duty access ramp when 5052 would suffice leads to higher costs and difficult fabrication without measurable performance gains. Procurement must align mechanical requirements with service conditions rather than defaulting to the “strongest” alloy.

- Assuming All Patterns Are Equivalent: Choosing diamond tread for industrial walkways may result in insufficient traction under wet conditions. Pattern design should be guided by application-specific slip-resistance data.

- Ignoring Surface Flatness Tolerances: Especially in large-format sheets, poor flatness can cause installation issues or compromise aesthetics. Look for mill-certified tolerance specifications based on ASTM B632 or EN 1386.

- Specifying Based on Nominal Thickness Alone: As previously discussed, failing to distinguish base thickness from total thickness can result in structural underperformance.

🔍 For reliable installations, always request a mill test report (MTR) and product datasheet distinguishing base gauge from total profile.

These mistakes often stem from a lack of collaboration between engineers, purchasers, and fabricators. A comprehensive specification—covering alloy, thickness, pattern, finish, temper, and tolerances—prevents downstream conflicts and performance surprises.

Supplier Qualification: What Separates Vendors from Manufacturing Partners

Beyond materials, the supplier’s engineering depth, documentation standards, and logistics practices are strong indicators of long-term reliability. Procurement professionals should consider the following:

- Certification Transparency: Reputable suppliers—like Yishang, a RoHS and ISO 9001 certified manufacturer—will provide up-to-date certificates, material test reports, and compliance declarations aligned with ASTM B209 or EN 485.

- Processing Capability: Checker plate may require laser cutting, custom bending, or mounting hole prep. Suppliers offering value-added fabrication reduce time-to-assembly and ensure specification adherence.

- Dimensional Consistency: Request data on squareness, flatness, and tread depth. These impact panel alignment in flooring, decking, and machine guarding applications.

- Packaging & Damage Prevention: Tread patterns are vulnerable during transit. Ask about edge protection, anti-slip separators, and stacking methodology.

- Technical Engagement: Strong partners offer CAD-based design reviews, surface treatment advice, and tolerancing validation during quotation.

🛠️ Insight: The best manufacturers act as engineering allies—not just metal vendors. Yishang supports B2B clients with custom design reviews, prototyping, and end-to-end packaging solutions.

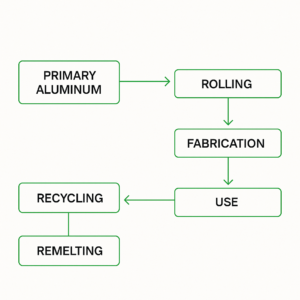

Part 5: Trends in Sustainability and Aluminum Checker Plate Procurement Strategy

Checker plate has historically been specified for its durability and safety, but its role is expanding as ESG policies, carbon accounting, and digital traceability reshape how industrial materials are sourced and evaluated. This section examines emerging trends that procurement professionals should monitor.

Lightweighting Strategies in EVs, Modular Construction & Logistics

Global industries—from electric vehicles to prefab modular systems—are demanding more performance from less material. The strength-to-weight ratio of aluminum checker plate makes it a top choice for lightweighting initiatives:

- EV Platforms: Reducing vehicle weight increases battery efficiency and payload capacity. Aluminum tread plate is increasingly used in EV truck beds, cargo ramps, and battery pack enclosures.

- Modular Floor Panels: In prefabricated structures, checker plates reduce dead load while improving slip resistance and durability. Their compatibility with fast-installation flooring systems is a growing procurement driver.

- Freight & Transport: Weight savings on aircraft cargo floors and trailers allow for higher payload efficiency. Many logistics firms now request weight-optimized aluminum sheet with base-gauge traceability.

♻️ Yishang supplies precision-gauge aluminum checker plates tailored for high-strength, low-weight system integration in EVs and industrial trailers.

Sustainable Sourcing and Lifecycle Analysis (LCA) Metrics

Beyond durability, aluminum’s infinite recyclability makes it an attractive material for green procurement. But institutional buyers now require full transparency across the supply chain:

- Recycled Content Disclosure: Leading manufacturers now offer checker plates with 70–90% recycled content. Always clarify post-consumer vs. post-industrial origin.

- Carbon Footprint Reporting: Request CO₂e data related to smelting, rolling, coating, and transport. More public-sector projects now require EPDs or LCA documentation.

- Green Certification Compatibility: Materials that meet LEED, BREEAM, or WELL Building requirements support compliance in construction and infrastructure bids.

🌍 Yishang can provide mill-sourced material certificates and supports full-chain transparency for aluminum procurement under global ESG frameworks.

Digital Traceability and BIM-Ready Material Integration

The aluminum checker plate of the future will be a traceable, data-rich asset. Forward-looking manufacturers now support:

- QR & RFID Tagging: Plates can be embedded with batch and production metadata for project documentation, traceability, and warranty control.

- BIM Integration: CAD-ready assets are essential for infrastructure projects using BIM workflows. Checker plate models with tolerancing, thickness, and pattern metadata are increasingly requested.

- Blockchain Certification (Emerging): Projects in aerospace and defense are beginning to pilot blockchain-based certification trails for key aluminum components.

📐 Yishang offers BIM-compatible aluminum checker plate design files and traceability labeling for OEM and EPC clients requiring digital compliance.

Frequently Asked Questions (FAQ)

What is the difference between 5052 and 6061 aluminum checker plate?

5052 is a non-heat-treatable, high-magnesium alloy known for excellent corrosion resistance and moderate strength, ideal for marine and outdoor environments. 6061 is a heat-treatable alloy with higher structural strength but is more difficult to weld and bend due to its brittleness in T6 condition.

How do I determine the correct thickness for aluminum tread plate?

Use base metal thickness, not total sheet thickness. Nominal thickness includes raised bars and may misrepresent actual structural capacity. Reference standards like ASTM B209 for tolerance accuracy.

Is aluminum checker plate suitable for marine environments?

Yes. Use 5052, 5083, or 5086 marine-grade aluminum with high magnesium content to resist saltwater corrosion. Ensure proper finishing and drainage in deck applications.

Can aluminum checker plate be powder coated or anodized?

Yes. Powder coating offers both corrosion protection and color options, but requires proper surface preparation. Anodizing works well but may produce uneven tone over raised tread patterns.

What kind of slip resistance does checker plate provide?

Patterns like 5-bar tread are industry standard for wet and oily industrial conditions. For extreme safety, apply grit-based non-slip coatings over the surface.

How do I choose a reliable aluminum checker plate manufacturer?

Look for suppliers with ISO 9001, RoHS, and ASTM/EN compliance. A trustworthy OEM will offer mill test reports (MTRs), CAD support, dimensional inspection records, and proper export packaging. Contact our engineering team at Yishang to discuss your project needs.