I. Introduction: The Engine of Modern Precision Manufacturing

In today’s competitive manufacturing landscape, precision, efficiency, and reliability are not just goals—they are imperatives. From aerospace components with micron-level tolerances to automotive parts produced by the million, the technology enabling this transformation is the machining center.

This guide moves beyond surface-level definitions. It offers a strategic, application-focused overview tailored for procurement managers, engineers, and industrial buyers who must understand how machining center technology directly impacts cost structures, cycle times, and final part quality. From component architecture to selection criteria and future trends, we provide a clear framework to evaluate capabilities, justify investments, and align machine tools with business outcomes.

II. Precision Engine Anatomy: How Core Components Drive Performance

Understanding the key components of a machining center is not just a technical exercise—it’s essential to evaluating machine capability and alignment with production requirements. Every subsystem represents a trade-off between throughput, precision, rigidity, and operational cost, which makes detailed knowledge essential to strategic sourcing.

The Brain: The CNC Controller and HMI

The CNC controller acts as the operational core, converting digital G-code into exact motion. The quality of the controller and its Human-Machine Interface (HMI) determines not only processing speed but also how intuitively operators can handle setups, offsets, and error recovery. For buyers, this translates to shorter onboarding cycles, less downtime, and fewer operator errors.

The Heart: The Spindle System

The spindle, responsible for rotating the cutting tool, has a direct impact on surface finish, material compatibility, and cycle time. Selecting the right spindle system defines the performance envelope:

- Belt-Drive Spindles: General-purpose and economical. They offer adequate torque and are suitable for steels and basic operations.

- Direct-Drive Spindles: High-speed, vibration-resistant, ideal for aluminum and mold finishing.

- Geared-Head Spindles: Designed for torque-intensive operations in hard-to-cut alloys like titanium.

| Spindle Drive Technology Comparison | ||||||

|---|---|---|---|---|---|---|

| Drive Type | Mechanism | Max Speed (RPM) | Torque Profile | Precision / Vibration | Typical Applications | Relative Cost |

| Belt-Drive | External motor with belts and pulleys | Moderate (8,000-12,000) | Balanced torque; cost-effective | Moderate; potential vibration | Steel roughing, general-purpose machining | Low |

| Direct-Drive | Motor directly coupled to spindle | High (12,000-40,000+) | High-speed optimized; low torque at low RPM | Minimal vibration; excellent precision | Aluminum finishing, high-speed contours | Medium to High |

| Geared-Head | Motor drives spindle through gearbox | Low (<8,000) | High torque for tough cuts | Can produce more vibration | Titanium, Inconel, heavy-duty industrial materials | High |

The Hands: The Automatic Tool Changer (ATC)

The ATC enables seamless transitions between tools, reducing cycle time and manual intervention. In high-mix production, large-capacity ATCs can support complex multi-tool programs while minimizing idle time. Faster tool changes also extend spindle-on time, directly impacting output per shift.

The Skeleton & Foundation: Machine Structure and Workholding

A rigid cast-iron frame absorbs vibration and resists thermal deformation, preserving accuracy across long production runs. Workholding systems—vises, tombstones, custom fixtures—must be chosen with equal care. Even micro-movements can compromise tolerances in aerospace, medical, or die/mold parts.

III. The Core Showdown: VMC vs. HMC — A Strategic Production Decision

Choosing between a Vertical Machining Center (VMC) and a Horizontal Machining Center (HMC) goes beyond technical preference—it’s a production strategy choice with lasting cost and efficiency implications.

A VMC, featuring a vertical spindle, is generally simpler to operate and more cost-effective upfront. It suits prototyping, single-sided machining, and small-to-medium batch sizes. However, chip evacuation remains a persistent drawback: without gravity-assisted clearing, chips often pile on the workpiece, negatively impacting surface finish and tool longevity.

An HMC, by contrast, mounts the spindle horizontally and is designed for volume and uptime. Using tombstone-style fixtures, multiple sides of a part can be machined in one cycle. More importantly, when paired with Automatic Pallet Changers (APCs), HMCs enable near-continuous operation. While one pallet is being machined, another can be prepped offline—drastically reducing non-cutting time. As a result, spindle utilization can rise from ~25% (typical of VMCs) to over 80% on HMCs, especially in high-throughput environments.

| Feature Vertical Machining Center (VMC) Horizontal Machining Center (HMC) | ||

|---|---|---|

| Spindle Orientation | Vertical (perpendicular to the table) | Horizontal (parallel to the table) |

| Ideal Use Cases | Flat parts, prototypes, general machining | Multi-face machining, production scaling, unmanned shifts |

| Chip Evacuation | Moderate (chips accumulate on part surface) | Excellent (chips fall away, prolonging tool life) |

| Productivity | Lower (idle during setups) | High (offline setups enable continuous cutting) |

| Automation Potential | Limited (manual handling common) | High (pallet systems, multi-face setups) |

| Initial Investment | Lower | Higher (but often better long-term ROI) |

From a procurement standpoint, the decision rests on output mix, automation goals, and operator skill base. A VMC may support flexible R&D or job shop environments. An HMC is better suited to dedicated product lines where cycle time and consistency drive margins.

IV. The Fifth Axis: Unlocking Geometric Freedom and Process Efficiency

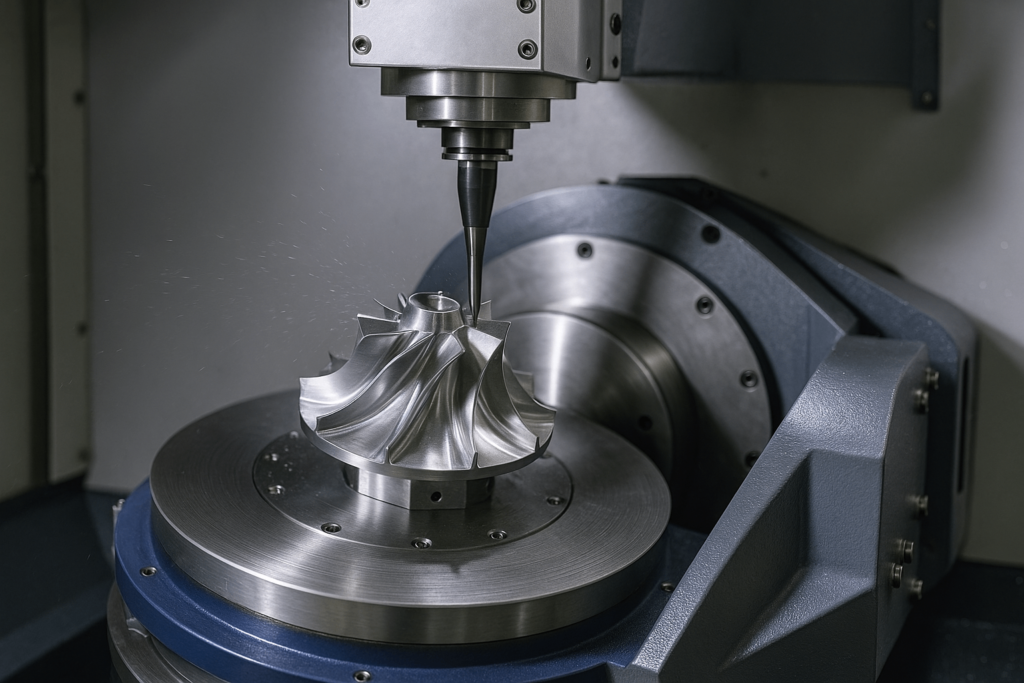

Adding fourth and fifth axes to the traditional XYZ setup transforms a machining center from a 3D profiler into a full-contour sculpting system. But not all 5-axis configurations are equal. The choice between 3+2 machining and simultaneous 5-axis control is central to understanding capability vs. complexity.

- 3+2 Positional Machining involves orienting the part using the rotary axes and locking them, while standard 3-axis motion executes the cut. It’s ideal for accessing multiple faces of a part without refixturing, reducing setup time and human error.

- Simultaneous 5-Axis Machining allows all axes to move at once, continuously adjusting tool angle and position. This enables intricate contours, undercuts, and smooth transitions that are impossible with positional-only methods.

For complex parts—such as impellers, orthopedic implants, and turbine blades—simultaneous 5-axis is often non-negotiable. It ensures uniform tool engagement, reduces cycle time, and improves surface finish by eliminating abrupt toolpath transitions.

From a cost-benefit perspective, investment in 5-axis capacity should be guided by:

- Part Complexity and Geometry: If parts require multiple operations or complex contours, 5-axis reduces setups and potential misalignment.

- Precision Requirements: Simultaneous motion eliminates compound tolerance stacking.

- Lead Time Pressure: With fewer setups and reduced handling, 5-axis often shortens turnaround time.

For OEMs or advanced job shops, acquiring 5-axis capability unlocks contracts previously inaccessible due to geometric or tolerance limitations. For high-mix operations, 3+2 machining on a trunnion-style machine may offer the best balance of flexibility and cost control.

V. Industry Applications: Where Machining Centers Prove Indispensable

Machining centers are not one-size-fits-all—they are precision assets adapted to industry-specific challenges. In each vertical, the balance between materials, geometry, tolerance, and throughput defines the optimal machine configuration.

- Aerospace: Lightweight, high-strength materials like titanium and Inconel demand rigid frames, high-torque spindles, and vibration control. Dimensional consistency across long parts and complex surfaces is critical, especially for airframe, turbine, and bracket components.

- Medical Devices: Components such as orthopedic implants, surgical instruments, and dental prosthetics require micron-level repeatability and flawless surface finish. Simultaneous 5-axis machining and thermal compensation features help meet stringent regulatory and biocompatibility requirements.

- Automotive: For high-volume parts like cylinder heads, transmission housings, or suspension components, productivity and uptime trump all. Horizontal machining centers equipped with pallet changers and high-capacity ATCs deliver the needed throughput with minimal operator intervention.

- Energy Sector: Steam turbines, compressor blades, and valve bodies—often in heat-resistant alloys—require deep cavity milling, high feed rates, and chip clearance optimization.

- Industrial Machinery: General-purpose parts such as molds, frames, and jigs benefit from flexible machines capable of switching between steel, aluminum, and copper alloys. Here, rigidity and fast tool changeovers are more valuable than ultra-high RPMs.

Strategic buyers must align machine selection with core part families, production cadence, and quality control benchmarks. For OEMs and contract manufacturers alike, choosing based on actual part behavior—not just catalog specs—can mean the difference between meeting lead times or missing margins.

VI. Beyond Speed: Automation, Uptime, and ROI in Focus

While cutting speed and tool sharpness often dominate discussions, true competitiveness stems from spindle uptime, automation, and process reliability. A machining center that runs consistently and autonomously drives profitability more than raw feedrate numbers.

Traditional setups yield just 25–30% spindle utilization due to manual part changeovers, probing, and idle periods. However, integrating automation elements like:

- Automatic Pallet Changers (APC)

- Robotic Loaders and Unloaders

- Tool Life Monitoring Systems

- In-Process Measurement and Compensation

…can raise active spindle time to 85% or higher. That level of output does not just affect throughput—it redefines operational efficiency per square meter.

For procurement teams, ROI must be assessed not only on machine price but on total system productivity. Does the configuration support unattended operation? Can parts be staged or inspected in parallel? Are tool failures detected and corrected before scrap is created?

In many facilities, a slightly higher capital outlay for automation-ready models is offset within months by labor savings, higher daily part counts, and reduced QC intervention. In this light, a machining center becomes not just a production tool, but a resilient process platform that scales with volume and demand.

VII. Choosing the Right Fit: Procurement Criteria That Matter

Selecting a machining center is a capital-intensive decision that directly affects productivity, flexibility, and return on assets. For B2B procurement professionals, especially those sourcing on behalf of OEMs or contract manufacturers, success hinges on matching machine capability with specific production demands.

1. Work Envelope and Travel Range

Ensure the machine accommodates your largest parts with buffer space for fixture clearance and tool overhang. Underestimating travel limits future adaptability, while overestimating adds unnecessary cost and footprint.

2. Spindle Power and Speed Profile

Match spindle torque and RPM range to your dominant material mix. For aluminum and plastics, high-speed, low-torque spindles excel. For stainless steels or nickel alloys, torque-intensive, lower-RPM models prevent stalling and tool degradation.

3. Tool Magazine Capacity and ATC Speed

A larger tool magazine benefits high-mix or multi-operation parts, minimizing tool changeover interruptions. Evaluate tool-to-tool swap speed and tool load capacity to support 24/7 operations.

4. Control Platform and Integration Ecosystem

Is the CNC controller compatible with your CAM workflows, ERP systems, and factory digital twin architecture? Look for open interfaces, adaptive control features, and built-in simulation tools for error-proofing complex toolpaths.

5. Structural Rigidity and Thermal Management

Heavy-duty castings, linear guideways, and thermal compensation systems preserve tolerances over long cycles and across ambient shifts. Consider machines with closed-loop feedback and spindle cooling for high-precision work.

6. Service Infrastructure and OEM Support

Beyond the machine itself, assess the vendor’s service reliability, parts availability, and diagnostic capabilities. Remote monitoring, predictive maintenance alerts, and localized field support are critical uptime factors.

The ideal machine isn’t necessarily the one with the most features—it’s the one with the right features for your part mix, growth outlook, and quality targets. Strategic sourcing involves future-proofing, not just technical matching.

VIII. Troubleshooting and Maintenance: Keeping Performance Consistent

Even the most advanced machining center is subject to wear, vibration, and occasional failure. Proactive diagnostics and failure mode awareness extend machine lifespan and ensure consistent output quality.

Common Symptoms and Root Causes

- Spindle Vibration or Chatter: May result from tool imbalance, worn bearings, or thermal expansion. Early signs include surface waviness or inconsistent cutting noise.

- Repeatability Drift: Typically caused by loose ball screws, encoder misalignment, or ambient temperature shifts.

- Unexpected Tool Breakage: Often linked to improper tool loading, contaminated holders, or aggressive feed/speed ratios beyond spec.

Preventive Maintenance Tactics

- Condition Monitoring: Install vibration, temperature, and spindle load sensors to detect performance degradation in real time.

- Routine Calibration: Regularly check probing systems, encoders, and axis travel accuracy to prevent cumulative errors.

- Fluid Systems Inspection: Maintain clean coolant, lubrication, and pneumatic circuits to avoid overheating, residue buildup, and control malfunction.

By embedding maintenance into the production plan—not treating it as a reactive step—teams preserve machine geometry, reduce unplanned downtime, and protect part quality. For facilities producing high-value components, maintenance is not a cost—it’s a quality assurance tool.

IX. Looking Ahead: Machining Centers in the Era of Industry 4.0

The role of machining centers is shifting from standalone equipment to intelligent, interconnected assets. In Industry 4.0 environments, a machine is no longer just a subtractive tool—it’s a node within a data-rich production network.

Key Emerging Trends

- Digital Twin Integration: Virtual replicas of machines allow manufacturers to simulate toolpaths, predict failures, and validate setups before cutting begins. This reduces scrap, enhances scheduling, and bridges engineering and shop floor teams.

- AI-Enhanced Toolpath Optimization: Real-time adaptive controls can adjust speeds and feeds dynamically based on sensor data, reducing tool wear and improving consistency across complex geometries.

- Predictive Maintenance via IIoT: By analyzing vibration, temperature, spindle load, and cycle anomalies, intelligent systems can anticipate failures—scheduling service before breakdowns occur.

- Open Protocol Connectivity: Machines built with MTConnect or OPC UA compatibility enable seamless integration with MES, ERP, and quality tracking systems—streamlining the entire production flow.

For procurement teams, this evolution raises new evaluation criteria. It’s no longer just about horsepower or table size—it’s about long-term integration, adaptability, and data contribution. A future-proof machining center must fit not only your current parts, but your factory’s digital roadmap.

X. Conclusion: Turning Capability Into Competitive Advantage

Machining centers are the heartbeat of modern manufacturing—from precision medical implants to engine components produced in the millions. But their true value is unlocked when configuration, process planning, and factory strategy align.

For overseas B2B buyers sourcing from Asia or managing global supply chains, the decision goes beyond features. It involves total lifecycle cost, serviceability, automation potential, and digital integration readiness.

A well-selected machining center doesn’t just cut parts—it enables:

- Repeatable quality under tight tolerance bands

- Cycle time reduction across shifting batch sizes

- Capacity scaling without proportional labor increases

- Smooth integration into digital manufacturing ecosystems

When these capabilities converge, machining centers become not just assets—but strategic levers for global competitiveness.

As a custom CNC machining center manufacturer based in China, YISHANG has delivered high-precision machining solutions for clients in the mold industry, aerospace OEMs, and electronics sectors across North America, Europe, and Southeast Asia. With multi-axis machining systems and flexible automation-ready configurations, we support global buyers seeking production scalability and long-term return on investment.

XI. FAQs: Key Questions About Machining Centers

What is a machining center and how does it differ from a CNC mill?

A machining center is a highly automated CNC machine tool capable of performing multiple machining operations in one setup, typically equipped with an automatic tool changer (ATC), enclosure, and programmable coolant. Unlike basic CNC mills, machining centers are optimized for volume, repeatability, and unattended operations.

What is the difference between HMC and VMC?

Horizontal Machining Centers (HMCs) have horizontally oriented spindles and excel in multi-face machining and chip evacuation. Vertical Machining Centers (VMCs), with vertical spindles, are better suited for flat parts and simpler setups.

When should I invest in a 5-axis machining center?

If your parts involve complex contours, undercuts, or multiple refixturing steps, 5-axis machining can drastically reduce setups and enhance accuracy.

How does automation improve machining ROI?

By increasing spindle utilization and enabling lights-out manufacturing, automation systems like APCs and tool monitoring reduce idle time, labor reliance, and scrap risk.

What is predictive maintenance in CNC machining?

It refers to real-time monitoring of machine health using sensors (vibration, heat, load) to prevent unexpected breakdowns. This supports uptime and consistent part quality.

How much does a machining center cost?

Pricing varies widely based on size, axis count, automation features, and brand. Entry-level 3-axis VMCs may start around $50,000–$80,000, while advanced 5-axis systems with high-end automation and precision can exceed $500,000. Long-term ROI often justifies the initial capital when paired with consistent utilization and maintenance.