Introduction: Addressing System Stability Challenges in Industrial Procurement

For international OEMs and wholesale procurement managers operating across sectors like HVAC, energy storage, and water treatment, system reliability is non-negotiable. Amid fluctuating fluid pressures and rising performance demands, stainless steel expansion tanks have become a key determinant of system durability, safety, and lifecycle cost-effectiveness.

Rather than presenting a product-centric overview, this article unpacks the strategic and technical factors wholesale buyers must consider—from material integrity to compliance documentation. It reflects YISHANG’s 26+ years of OEM-focused manufacturing experience, without sounding like an advertisement.

The Functional Role of Stainless Steel Expansion Tanks

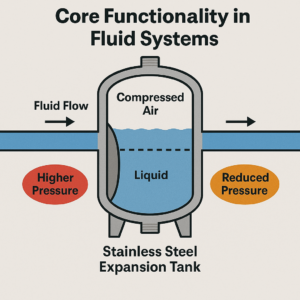

Core Functionality in Fluid Systems

Expansion tanks serve a singular yet critical role in closed-loop fluid systems: they absorb excess pressure due to temperature-induced expansion. Without them, fluctuations stress joints, pumps, and valves—leading to system fatigue and leakage.

Stainless steel variants outperform polymer or coated steel alternatives thanks to their:

- Superior corrosion and pressure resistance

- Extended durability under high-temperature conditions

- Stability in chemically aggressive or high-salinity environments

These traits make them ideal for sectors with intensive duty cycles and exposure to harsh conditions.

Why Stainless Steel Is the Material of Choice

For professional buyers, material selection isn’t about aesthetics—it’s about lifecycle optimization. Between 304 and 316 stainless steel, the difference in performance is notable:

| Grade | Corrosion Resistance | Typical Use Case |

|---|---|---|

| 304 | Good | General HVAC, indoor systems |

| 316 | Excellent (molybdenum alloyed) | Marine, desalination, chemical processing |

When selected correctly, stainless steel helps buyers reduce failure rates, extend maintenance cycles, and enhance ROI.

Procurement Priorities: What B2B Buyers Actually Care About

Beyond Price: Evaluating Total Cost and Risk

Procurement officers often focus on unit price—but seasoned professionals know that procurement success lies in minimizing:

- Product variation in bulk batches

- Post-installation failure rates

- Non-compliance with target market standards (e.g., EU RoHS)

Key procurement questions include:

- Can the supplier ensure consistent dimensions and port placement?

- Is the welding technique uniform across units?

- Will the documentation match customs and quality audit needs?

Specifications That Streamline Procurement

B2B buyers often work with engineering and compliance teams. Having tanks that meet both sets of criteria simplifies internal approvals. Common specs include:

- Working pressure & burst threshold

- Thread compatibility (BSP/NPT)

- Mounting interface options (wall, rack, skid)

- Traceable production codes

With YISHANG, purchasers receive not only the product but also CAD files, hydro-test data, and RoHS/ISO documentation in the buyer’s preferred format.

From Design Intent to Final Product: The Customization Chain

Practical Design Considerations

Every OEM project is different. For instance:

- In battery storage systems, tank orientation must match vertical clearance

- In medical cooling systems, inlet placement affects pump efficiency

- In agriculture, tanks must be weather-sealed and vibration-resistant

This level of variation demands supplier flexibility. YISHANG supports:

- Co-design based on engineering drawings

- Adaptable fabrication windows for varying volumes

- Labeling and documentation tailored to reseller needs

Most Common Customization Requests

To help procurement teams pre-plan, here are the five most frequent modifications we deliver:

- Tank capacity scaling: from 0.5L to 1000L

- Material switch: 304 to 316 or vice versa

- Port type: Flanged, threaded, quick-connect

- Surface finish: Matte, brushed, polished

- Mounting adapters: Pre-welded or bolted flanges for integration

By building this flexibility into our systems, buyers avoid post-purchase retrofits that delay deployments.

Manufacturing Integrity: Ensuring Repeatable, Reliable Performance

Materials and Quality Verification

YISHANG sources steel only from certified mills. Each batch is tested for:

- Composition (chromium/nickel/molybdenum ratios)

- Grain integrity

- Weldability and thickness consistency

Material reports are issued in PDF with third-party lab options available.

Controlled Fabrication Flow

All expansion tanks follow a tightly controlled flow:

- Laser cutting for part precision

- CNC bending to maintain tolerances

- TIG welding under inert gas shielding

- Hydrostatic leak testing to meet or exceed design pressure

We also support barcode tracking on every batch for traceability, ideal for buyers in regulated sectors.

Tailored for Industry-Specific Needs

Sector-Based Engineering Examples

| Industry | Key Tank Requirement |

|---|---|

| HVAC | Thermal expansion tolerance, compact form |

| Renewable Energy | High pressure + corrosion resistance |

| Food Processing | Sanitary-grade polishing and drainability |

| Medical Cooling | Stable performance under cyclic pressure |

| Irrigation | UV-resistant coating + rugged mounting |

Each industry requires more than just a tank—they need a fit-for-system solution.

Case Study Snapshot

An Australian solar integrator required 500+ tanks with 316L body, flanged ports, and 100% traceability. YISHANG delivered not only the parts but also full inspection certificates, export-ready packaging, and reorder blueprints, ensuring zero delays in customs and on-site installation.

Compliance and Inspection Protocols

Standards That Matter

Buyers exporting across borders need consistency in certification. YISHANG complies with:

- ISO 9001: Quality management

- RoHS: Material safety for electrical and thermal systems

- IP Ratings: Upon request for integration into control cabinets

Testing Procedures Performed

| Test Type | Purpose |

|---|---|

| Hydrostatic pressure | Leak prevention and burst integrity |

| Weld seam inspection | Visual + radiographic confirmation |

| Surface passivation check | Corrosion resistance verification |

| Serial trace tagging | Batch identification for audits |

With complete inspection packets shipped digitally and physically, clients reduce internal QA burden.

Procurement Strategy: Partnering for Lifecycle Success

Beyond Unit Cost: Considering TCO

For global buyers, the lowest quote is not always the best choice. Stainless steel tanks from unreliable suppliers may fail prematurely due to:

- Porous welds

- Mismatched port threads

- Undocumented material substitutions

Conversely, investing in quality tanks lowers:

- Maintenance costs

- Field failure incidents

- Downtime due to replacements

The YISHANG Value Proposition (Soft-Sell)

Instead of hard-selling, here’s what buyers say:

“What impressed us wasn’t just the tank quality—but the documentation readiness, packaging detail, and responsiveness during design iterations.” — German OEM client

With scalable production, full customization, and English-language tech support, YISHANG is positioned not just as a vendor, but a strategic metal partner.

Conclusion: Buying Tanks Shouldn’t Be a Guessing Game

In high-demand systems, stainless steel expansion tanks are not interchangeable commodities. They’re technical components that demand specification, certification, and accountability.

When the goal is project success—not just component sourcing—industrial buyers turn to partners who understand both the manufacturing floor and the procurement matrix.