In the world of industrial manufacturing, a component’s failure can halt a multi-million-dollar production line. Often, the culprit isn’t a complex system but a single, overlooked metal spring. This scenario highlights a critical truth: selecting a spring is a high-stakes engineering decision that directly impacts product reliability, safety, and the total cost of ownership.

This guide moves beyond a simple catalog of spring types. Instead, we explore the distinct “personality” of each spring—its behavior under stress, its endurance over millions of cycles, and its suitability for specific tasks. For engineers and procurement professionals, understanding these traits is key to preventing costly failures and making the most intelligent sourcing decisions when working with a trusted custom metal spring manufacturer in China.

Part 1: The Physical “Bottom Line”—A Spring’s Unbreakable Performance Boundaries

Before choosing a spring, it’s essential to understand the physical rules that govern its performance. These are not abstract theories but non-negotiable constraints that dictate how a spring behaves under load. A miscalculation here can directly result in failure, downtime, and rework.

At the core of spring physics lies Hooke’s Law, which provides both predictability and a cautionary boundary. Within its elastic limit, a spring obeys the linear formula (F = -kx), where force is proportional to displacement. This reliable predictability is what allows engineers to design around springs with confidence. However, exceeding that elastic limit leads to permanent deformation—the spring won’t return to its original shape, and the system that relies on it may be compromised.

Two parameters critically define a spring’s functional character: stiffness and fatigue life. Stiffness (or spring rate) is the resistance a spring offers against deformation, typically defined by its material, wire diameter, coil diameter, and active coil count. It determines how much load the spring can handle without excessive compression or extension.

Fatigue life is equally vital—perhaps more so in applications where repetitive motion is involved. A spring may not break from one-time overloading but can fail after a million small cycles if not properly engineered. Fatigue life is influenced by material selection, surface finish, operating environment, and stress ranges. This is why treatments like shot peening—creating a compressive layer that impedes crack propagation—are often used in high cycle torsion springs for industrial systems.

Part 2: Design Evolution Under Three Basic Forces—The Helical Spring Showdown

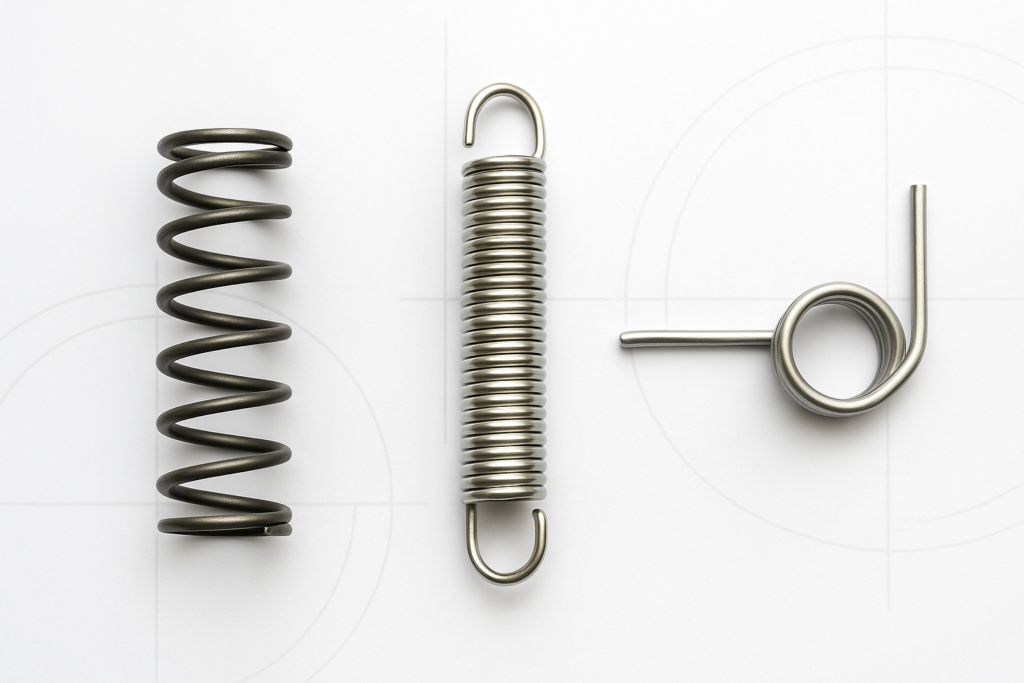

Helical springs dominate the mechanical world, not because they are simple, but because they’ve been refined to meet diverse and demanding requirements. Understanding their application is understanding how mechanical energy is managed in three distinct modes: compression, extension, and torsion.

Compression springs resist axial loads that push them inward. Their open-coil structure stores energy as they’re compressed. The cylindrical form is most common, but variations like conical or barrel shapes exist to solve real-world challenges. Conical springs allow coils to telescope into each other, reducing height under load. Barrel or hourglass forms reduce lateral deflection and the tendency to buckle under axial loads—essential in long or narrow configurations often found in spring components for vending machines.

Extension springs operate in the opposite direction. They absorb energy when pulled apart. But more than the spring body, it’s the hook design that dictates reliability. Standard hooks are simple but prone to stress concentration, particularly in high-cycle environments. Machine hooks offer improved strength, and double-loop designs distribute the stress more evenly. For truly critical applications, eliminating hooks altogether in favor of threaded inserts provides unmatched durability, especially for OEM extension springs used in energy or transportation applications.

Torsion springs work by twisting rather than stretching or compressing. They are typically used in hinges, counterbalances, and clutches. One of the most overlooked factors in torsion spring design is winding direction. Torsion springs must be loaded in the direction that tightens the coil; loading it backwards can cause premature failure. In high-torque systems or where load balance is needed, double torsion springs—with two coils wound in opposite directions—are used to provide symmetry and strength.

Part 3: The Rule Breakers—Specialty Metal Springs for Extreme Engineering Problems

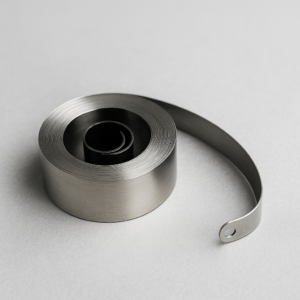

Standard springs can’t always meet performance requirements. Some applications call for a force that remains constant throughout a motion range, or a design that can handle very high axial loads in a compact space. In these cases, specialized springs fill the gap.

Constant force springs solve the problem of force variation. Built from pre-stressed steel strips, they uncoil to provide nearly uniform force—ideal for smooth retraction in cable reels or adjustable counterbalances. These springs behave differently from helical ones, acting more like tape measures than coils. They are especially effective in medical-grade spring assemblies and precise automation devices.

Belleville washers—also called disc springs—excel in space-constrained environments where very high force is needed. Their conical shape allows multiple washers to be stacked, customizing both load and deflection behavior. Stacked in parallel, they increase force. In series, they allow greater movement. Their ability to be “programmed” makes them indispensable in bolted joints or vibration damping systems.

Heavy-duty applications often require springs that bear immense loads without failing. Leaf springs are iconic in this category, used for decades in truck suspensions. Their multi-layered flat bar design provides flexibility with robustness. Volute springs, often overlooked, offer both high load capacity and compression into a minimal space, thanks to their sliding coil architecture—found in heavy presses and railway buffers.

Part 4: From Metal to Masterpiece—How Manufacturing Defines a Spring’s Final Performance

The blueprint is only the beginning. A spring’s performance is heavily influenced by how it’s manufactured. Two key processes—cold and hot coiling—are chosen based on wire diameter and desired characteristics.

Cold coiling is ideal for precision. Wire is wound at room temperature, allowing tighter tolerances and better surface finish. It’s commonly used for industrial compression springs, electronics, and small mechanical assemblies. In contrast, hot coiling is necessary for wire diameters beyond ~30 mm. The wire is heated above 850°C, made pliable, then formed into shape. This is typical in rail, mining, and heavy industrial use. However, it often requires additional heat treatment and finishing due to surface oxidation.

Shot peening, while technically a post-process treatment, plays a massive role in real-world performance. By bombarding the spring surface with small spherical media, a compressive stress layer is formed, greatly improving resistance to fatigue. In high-cycle applications—like robotic actuators or vibration-isolation systems—specifying shot peening can extend operational life by up to ten times.

Material also matters. High-carbon steels like A228 offer strength and cost-effectiveness but must be protected from corrosion. Stainless steels (302, 304, 316)—particularly 316 stainless steel springs for medical use—provide corrosion resistance but trade off some strength. Chrome silicon alloys resist high temperatures and shocks, making them perfect for extreme mechanical loads. Specialty metals like beryllium copper add non-magnetic and conductive properties for use in electronics or explosive environments.

Part 5: The Engineer’s Decision Checklist—Matching the Spring to the Application

Spring selection is never just about shape. It’s a multi-variable decision involving load conditions, space, environment, and lifecycle expectations. The most effective way to avoid failure—and ensure performance—is to walk through a disciplined set of engineering questions:

- What type of load will the spring experience—compression, extension, or torsion?

- What are the dimensional constraints—maximum solid height, diameter, and available installation space?

- What load must the spring bear, and how far should it travel?

- Will it be exposed to heat, moisture, chemicals, or other harsh conditions?

- How many cycles must it withstand? What’s the acceptable failure risk?

Answering these questions is critical when sourcing from an ISO 9001 spring supplier or evaluating options for custom metal springs for industrial applications. These considerations drive material choice, geometry, treatment processes, and ultimately cost.

Conclusion: Beyond “Type Selection,” Embracing “Engineering Matching”

Springs are deceptively simple. But the wrong choice—made without due diligence—can introduce catastrophic weak points into otherwise robust systems. The real goal isn’t to pick from a catalog, but to engineer a match between task and component. When that match is exact, the spring becomes an asset. When it’s not, it becomes a liability.

Why Work with YISHANG for Custom Spring Manufacturing?

With over 26 years in precision sheet metal and spring fabrication, YISHANG delivers high-quality, RoHS-compliant, ISO 9001-certified bulk spring supply and OEM spring manufacturing for industrial customers. We support global B2B partners in automotive, vending systems, energy storage, medical devices, and more.

Whether you’re sourcing industrial compression springs, high-cycle torsion springs, or OEM extension springs, YISHANG ensures your product’s reliability from design to delivery. As a trusted custom metal spring manufacturer in China, we understand the engineering that goes into every coil.

Need custom springs tailored to your application? Contact our team today to get a quote or request a prototype.

FAQ

Q1: What are the different types of mechanical springs?

A: Common types include compression springs, extension springs, torsion springs, and specialty springs such as constant force and disc springs.

Q2: How do I choose the right spring for my application?

A: Consider load type, space, environmental conditions, material, fatigue life, and required force-displacement ratio.

Q3: Does YISHANG provide OEM custom spring services?

A: Yes, YISHANG supports bulk OEM spring manufacturing with ISO 9001 and RoHS compliance, serving 50+ countries.