Redefining Metal Fabrication for Next-Gen Data Centers

The evolution of digital infrastructure is no longer gradual—it’s exponential. AI computing, edge devices, IoT integration, and streaming platforms are reshaping how and where data centers are built. But this growth is not only measured in megawatts or rack counts; it’s reflected in the changing expectations for the metal structures that enable these centers to operate.

For global procurement teams sourcing enclosures, cabinets, mounting systems, or structural frames, this shift means more than meeting specifications. The key challenge lies in sourcing engineered, standards-compliant, and deployment-ready systems that address application-specific challenges. YISHANG responds to this demand not with off-the-shelf metalwork, but with collaborative, precision-driven fabrication solutions that align with your operational goals. As an experienced OEM data center enclosure manufacturer, we specialize in long-term procurement partnerships tailored to hyperscale and modular facilities.

Moving Beyond Classification: What Actually Informs Fabrication Decisions

Why Traditional Data Center Categories Don’t Drive Sourcing

Terms like “hyperscale,” “colocation,” or “edge” may define IT strategies—but for B2B buyers focused on metal systems, those labels offer little guidance. Instead, physical deployment scenarios, environmental variables, and integration workflows determine what materials and fabrication methods are required.

Deployment Format Defines Structural Needs

Hyperscale deployments prioritize uniformity and mass manufacturing—requiring streamlined production of identical steel racks, cable trays, and bulk mounting assemblies. Edge applications, by contrast, often demand compact, weatherproof enclosures engineered for limited footprints and remote maintenance. Our IP67 outdoor enclosure data center solutions are particularly suited for extreme edge locations.

Physical Build Constraints Drive Design

Is the application wall-mounted, pole-mounted, or containerized? Each format shifts the tolerances and material demands. For instance, IP66/IP67-sealed outdoor units must integrate moisture-resistant finishes and NEMA-rated gaskets. Transportable containerized systems require lightweight metals and reinforced bracing.

Environmental Exposure Shapes Material Choices

Humidity, UV exposure, salinity, and ambient vibration are critical drivers. Coastal edge sites benefit from 316 stainless steel, while indoor hyperscale environments may rely on cost-effective galvanized steel with powder coatings. Material choices directly influence maintenance intervals and lifecycle cost. YISHANG supports you in optimizing these decisions with custom stainless steel enclosure manufacturing for data centers.

At YISHANG, we support technical reviews during the RFQ phase to guide metal selection and structure planning—ensuring precision before production ever begins.

Structural Shifts: How Design Evolution Is Reshaping Metal Requirements

From Static Infrastructure to Modular, High-Precision Systems

Modular Design = Manufacturing Precision

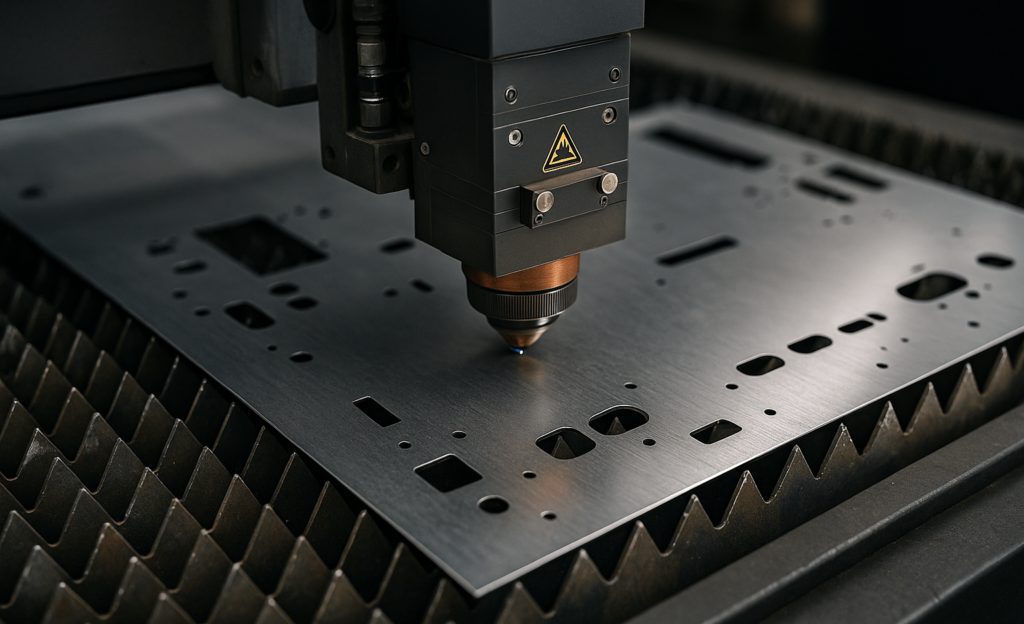

Today’s data centers increasingly use prefabricated modules shipped directly to site for plug-in deployment. This manufacturing model demands pre-cut, pre-drilled, powder-coated panels fabricated with sub-millimeter precision. Buyers now expect CNC tolerances of <±0.5 mm, batch traceability, and plug-ready hardware interfaces. YISHANG’s modular server rack cabinets supplier model is optimized for these fast-moving builds.

Higher Power Density = Increased Load Tolerance

Thermal loads per rack have increased dramatically, reaching beyond 30 kW per cabinet in some environments. This necessitates robust frame assemblies, airflow-compatible ducting support, and vibration-tolerant builds. Structural metal not only holds servers—it supports advanced cooling and integrated monitoring systems.

Quality Data Isn’t a Bonus, It’s a Requirement

Global procurement demands traceability—from MTRs (Material Test Reports) and salt spray test results to weld inspection logs and surface coating thickness records. Without ISO-certified QA processes, projects risk customs delays or compliance rejection.

At YISHANG, we don’t just provide bent metal. We deliver fully engineered metal systems with validation data aligned to procurement audits.

Application-Focused Data Center Types That Matter to Sourcing

Hyperscale Campuses: Repeatability and Speed

These mega-sites house thousands of racks and consume upwards of 100 MW. Their scale creates a need for:

- Pre-assembled rack frames

- Cable ladder supports

- Floor-mounted frames

- Equipment mounting kits with global compliance

Key Buyer Concern: Repeatability and certification. Batch documentation, predictable lead times, and consistent tolerances are non-negotiable.

Common Materials:

- Galvanized steel for strength and modular joining

- Aluminium for non-load-bearing infrastructure

- 304/316 stainless steel in cooling zones

YISHANG’s integrated ERP tracks orders from cutting to shipment, ensuring project timelines and conformance. As a trusted galvanized steel enclosure for data center builds, we support batch-standardized infrastructure needs.

Modular Data Centers: Compact Integration, High Customization

Procurement professionals dealing with modular builds must juggle high system density with diverse mechanical needs—from vented panels and heat shields to load-bearing structures and hinged access.

Typical Components:

- CNC-drilled control panel housings

- Powder-coated aluminium brackets

- Pre-wired subrack frames

- Dual-metal assemblies with grounding elements

The complexity of modular builds means fewer suppliers can meet full-cycle demands. YISHANG handles fabrication, coating, assembly, and testing under one roof—eliminating third-party risk and streamlining logistics. Our modular data center manufacturing capabilities include complete rack system integration.

Edge Deployments: High Variability, Harsh Conditions

Edge data centers are deployed near users—at EV charging stations, telecom towers, and urban microgrids. These applications demand:

- Anti-vibration chassis

- IP68-rated ingress protection

- EMI shielding for sensitive zones

Form factors vary widely. Buyers need a partner who can support rapid prototyping and ODM-level customization.

YISHANG’s edge enclosure line includes pole-, wall-, and surface-mounted enclosures with heat-reflective coatings, vented airflow options, and brand-specific form factors. Our edge data center metal enclosure custom options are engineered for region-specific conditions and rapid deployments.

Material Selection: Procurement Strategy for Lifecycle Performance

Selecting material isn’t just a sourcing decision—it’s a strategy. Proper materials affect not just strength, but installation speed, transport costs, and long-term maintenance.

| Material | Ideal Use | Benefits | Considerations |

|---|---|---|---|

| 316 Stainless Steel | Coastal or corrosive areas | High resistance, long life | Costlier, heavier |

| Galvanized Steel | Indoor structural frames | Affordable, durable | Requires treated coating |

| Aluminium | Modular & light transport | Light, corrosion-resistant | Less rigid, needs EMI finish |

| Brass/Copper | EMI zones, grounding | High conductivity | High raw material price |

YISHANG engineers consult buyers early to balance budget, weight, and performance. For instance, switching from steel to aluminium can reduce shipping weight by up to 35%, which impacts customs costs and installation lead time. Our role as a precision-focused OEM enclosure supplier makes this optimization seamless.

Regional Procurement Trends & Sourcing Responses

North America & Europe: ESG & Lifecycle Documentation

Buyers prioritize:

- RoHS & REACH compliance

- Lifecycle tracking and recycling programs

- Pre-configured modular delivery

YISHANG supports this with ISO 9001 processes, UL/NEMA/IP certifications, and digital batch reporting systems for end-to-end traceability.

Asia-Pacific: Fast Turnaround, High Urban Density

Metro growth drives demand for:

- Small-batch flexible production

- ODM-branded units

- Tight form factors for telecom & smart city use

Our fast prototyping and modular platform design give APAC buyers short lead times and precise fitment.

Middle East & Africa: Environmental Resilience

With high heat, dust, and salinity, buyers demand sealed builds with UV-reflective coatings and thermal expansion protection. Certification is key for customs clearance (e.g., G-Mark, SASO).

YISHANG offers pre-tested IP67/IP68 enclosures with custom coatings and region-specific labeling for seamless import.

What B2B Buyers Should Look For Beyond the Product

Why Integration Beats Individual Parts

Procurement is shifting away from buying separate items—what buyers want is systems. A valuable supplier today should:

- Review specs & adjust designs

- Fabricate to multi-standard compliance

- Assemble, label, and pre-kit for plug-in install

YISHANG offers:

- CNC precision fabrication

- NEMA/IP-rated enclosure sealing

- Full QA reports with every batch

- Labeling, kitting, logistics support

As a modular server rack cabinets supplier, we deliver end-to-end support across every production phase.

Certification Must Be Verifiable

From ISO 9001 audits to coating thickness sheets, what’s promised must be delivered. YISHANG simplifies compliance workflows with digital logs for:

- Welds and coatings

- MTRs and material specs

- NEMA/IP tests

- RoHS/UL/CE declarations

Final Thoughts: Why Metal Matters in Data Infrastructure

The data center supply chain is no longer about parts—it’s about engineered systems built for performance, compliance, and deployment agility. Sourcing teams need manufacturers who understand global data infrastructure demands—not just how to bend steel.

YISHANG builds enclosure systems that meet regulatory standards, reduce installation complexity, and perform reliably in the field. Whether it’s a high-volume hyperscale order or a complex modular ODM build, we help global buyers de-risk their sourcing and streamline deployment.

Reach out to YISHANG to discuss your enclosure procurement needs today.