Introduction: Why Motor Shaft Reliability Defines Supply Chain Success

In the global manufacturing ecosystem, one small failure can ripple across an entire production network. For industrial procurement managers, mechanical engineers, and OEM buyers, the most disruptive failures often stem not from complex systems—but from simple rotating parts like the motor shaft. A single shaft malfunction can lead to production downtime, warranty claims, and reputational damage. For overseas buyers in Europe and North America, finding a reliable custom motor shaft manufacturer in China that delivers precision and consistency is vital for protecting both cost efficiency and product quality.

At its core, the motor shaft is the bridge between electrical power and mechanical motion. It must deliver torque, endure dynamic loads, and maintain alignment under stress. This article explores the technical and quality principles that determine shaft reliability—from design and material selection to machining, heat treatment, and final inspection. Written from an engineering and supply chain perspective, it helps OEM and ODM buyers make informed sourcing decisions with long-term performance and quality assurance in mind.

Chapter 1: Failure Scene Investigation—Why Motor Shafts Fail (and How to Prevent It)

To engineer reliability, you must first understand failure. The most common motor shaft failure causes include fatigue, overload, and vibration-induced wear. These failure modes not only affect performance but can lead to sudden system collapse. Identifying and addressing these factors in the design and production stages is critical.

The Silent Killer: Fatigue Failure

Fatigue failure is the gradual and cumulative process of crack initiation and propagation due to cyclic stresses. It often starts in micro-defects—small surface scratches, tool marks, or keyway corners—where stress concentrates. These tiny imperfections expand under repeated loading until the shaft fractures completely. The fracture surfaces typically show concentric beach marks, the hallmark of progressive crack growth.

Prevention begins with proper design geometry and precise machining. Rounded fillets, smooth transitions, and high-quality surface finishing (Ra < 0.4 µm) significantly reduce stress concentration. Choosing the correct heat treatment also improves fatigue resistance by refining the microstructure and increasing surface hardness.

The Sudden Catastrophe: Overload Failure

Overload failure occurs when a shaft experiences torque or impact beyond its yield strength—usually due to equipment jams or operational shocks. The fracture is rough and fibrous, lacking the beach marks seen in fatigue. While less frequent, overload failures highlight the need for built-in safety factors during design. For industrial buyers, specifying accurate torque limits and verifying through finite element analysis (FEA) can prevent such incidents.

The Hidden Menace: Vibration and Geometric Defects

Even minor geometric defects—such as eccentricity or poor straightness—can cause imbalance and vibration. These vibrations propagate through bearings and couplings, accelerating fatigue. Implementing strict GD&T (Geometric Dimensioning & Tolerancing) controls and dynamic balancing standards like ISO 1940-1 ensures concentricity and rotational stability. A qualified shaft manufacturer in China should always perform CMM (Coordinate Measuring Machine) inspections to verify geometry before shipment.

Chapter 2: Building the Blueprint for Reliability—Design and Material Engineering

Design and material selection define a shaft’s mechanical integrity. A proactive motor shaft design guide considers geometry, load types, and working conditions, while material choice balances strength, machinability, and corrosion resistance.

Choosing the Right Material for Industrial Use

- AISI 1045 (Medium Carbon Steel): Economical and machinable; ideal for general-purpose shafts in machinery and pumps.

- AISI 4140 (Chromium-Molybdenum Steel): Excellent fatigue resistance and toughness; perfect for high-torque applications and EV components.

- AISI 4340 (Nickel-Chromium-Molybdenum Steel): Combines high tensile strength and impact resistance; used in aerospace and heavy industrial systems.

- AISI 316 Stainless Steel: Offers superior corrosion resistance for marine, food processing, or medical applications.

| Material Grade | Tensile Strength (MPa) | Hardness (HRC) | Key Benefit | Typical Application |

|---|---|---|---|---|

| 1045 | 570–700 | 45–55 | Cost-effective balance | Industrial motors, pumps |

| 4140 | 930–1080 | 54–60 | High fatigue strength | EV drivetrains, gearboxes |

| 4340 | 850–1130 | 35–45 | Impact resistance | Aerospace & heavy-duty shafts |

| 316 SS | ~580 | — | Corrosion protection | Marine & medical equipment |

Design Geometry and Stress Reduction

A well-engineered shaft geometry spreads loads evenly. Use fillets instead of sharp corners, avoid sudden diameter transitions, and ensure proper keyway dimensions. Employing FEA simulations during the design phase identifies potential weak points. For buyers, collaborating with suppliers offering design-for-manufacturability (DFM) feedback can reduce cost and improve durability.

Chapter 3: Machining Precision—Turning Blueprints into Reality

Precision machining turns theoretical design into a tangible, reliable component. For OEM buyers, verifying that your shaft manufacturer in China maintains consistent tolerances is vital.

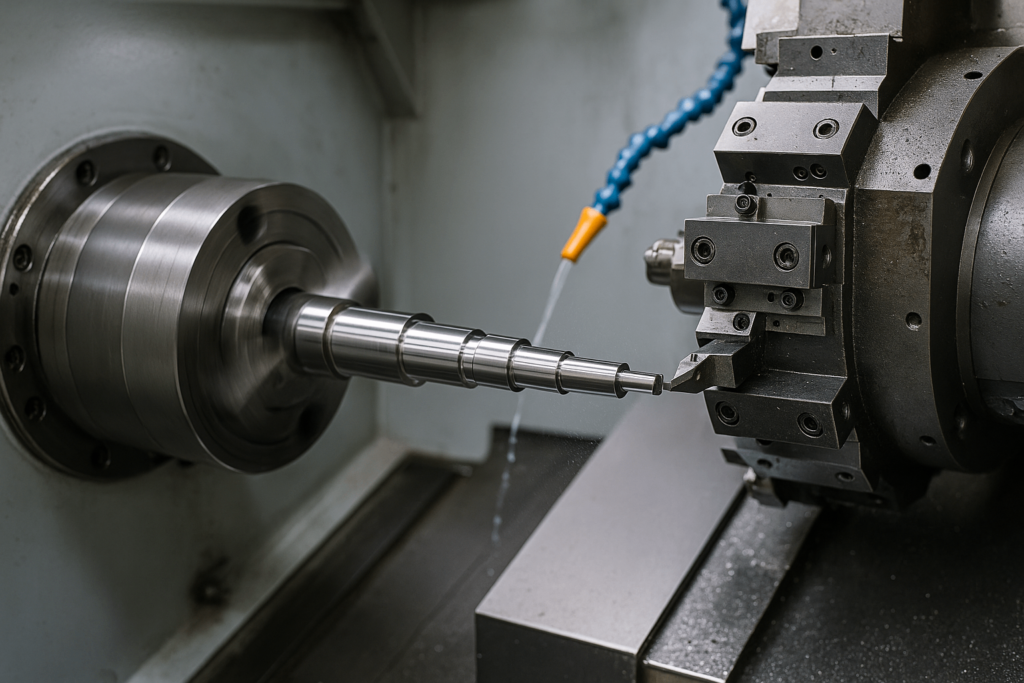

Modern CNC shaft machining integrates turning, milling, grinding, and drilling to achieve micron-level precision. Centerless grinding achieves perfect cylindrical form, while honing refines surface finishes to prevent premature wear. Typical tolerances are ±0.01 mm for diameter and <0.02 mm for runout. For high-speed motors, even minute deviations can cause destructive imbalance.

Batch consistency matters most in high-volume orders. A factory’s capability in tool calibration, fixturing accuracy, and process repeatability determines production quality. Deep-hole drilling and keyway broaching require vibration-free setups to preserve concentricity. Every step—from raw bar preparation to final packaging—must follow an SPC (Statistical Process Control) plan to guarantee dimensional repeatability.

Buyer Tip: Always request machining capability data, including CMM inspection reports and batch deviation logs. This transparency demonstrates the supplier’s maturity in process control.

Chapter 4: Heat Treatment—Optimizing Hardness and Longevity

Heat treatment is the backbone of shaft performance. It tailors the steel’s internal structure for strength, wear resistance, and fatigue life. The most common treatments include quenching & tempering (Q&T), induction hardening, and case hardening.

- Q&T increases hardness and tensile strength by forming martensite and then tempering for ductility.

- Induction hardening targets only surface areas like bearing seats, creating a hardened shell with a tough core.

- Case hardening adds a wear-resistant surface ideal for shafts under high sliding contact.

Precision in temperature control, soak time, and quenching rate ensures microstructural uniformity. Variations cause warping, cracking, or inconsistent hardness. Top-tier suppliers perform Rockwell hardness tests, metallographic inspection, and non-destructive crack testing after each batch.

Quality Assurance Note: Request full traceability with batch heat-treatment certificates. For European and North American buyers, such documentation is crucial for regulatory and warranty compliance.

Chapter 5: Inspection and Quality Assurance—From Verification to Certification

True reliability is verified, not assumed. A complete motor shaft quality control system covers dimensional, mechanical, and surface integrity inspections.

- Dimensional Accuracy: Verified by CMMs, laser micrometers, and roundness testers for GD&T compliance.

- Surface Integrity: Measured by profilometers to ensure Ra < 0.8 µm on bearing areas.

- Mechanical Verification: Conducted via tensile and hardness tests to confirm material performance.

Advanced factories implement PPAP (Production Part Approval Process) and FAIR (First Article Inspection Reports) to validate consistency before mass production. Statistical sampling under ISO 2859-1 standards ensures confidence in every shipment.

FAQ – Frequently Asked Questions:

- What causes motor shaft vibration? → Typically geometric imbalance or poor balancing during machining.

- What tolerance levels are acceptable? → Most industrial shafts maintain ±0.01 mm and <0.02 mm runout.

- Can YISHANG provide OEM and ODM customization? → Yes, all shaft designs are custom-engineered to your print or sample.

Conclusion: Partnering for Precision and Performance

A failure-proof motor shaft results from synergy between design, material science, and disciplined manufacturing. Every step—from geometry optimization to precision machining, heat treatment, and QA—contributes to consistent performance. For global OEM and ODM buyers, partnering with a supplier that treats tolerance as a science rather than a promise ensures stability across thousands of units.

YISHANG, with over 26 years of expertise in metal fabrication and certified under ISO 9001 and RoHS, provides custom motor shaft manufacturing in China for industries including automotive, construction, medical, vending, and energy. Our vertically integrated production ensures total control—from raw material to surface treatment and packaging.

📩 Contact us today for a quote or design consultation. Let’s engineer precision together—turning your motor shafts into the foundation of your product’s global reliability.